Device capable of improving power station boiler combustion value

A boiler combustion and power plant technology, applied in the direction of using a variety of fuel combustion, combustion methods, combustion types, etc., can solve the problems of short flame stroke, poor peak shaving performance, long ignition time, etc., to increase contact and flame propagation speed. , The effect of reducing slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

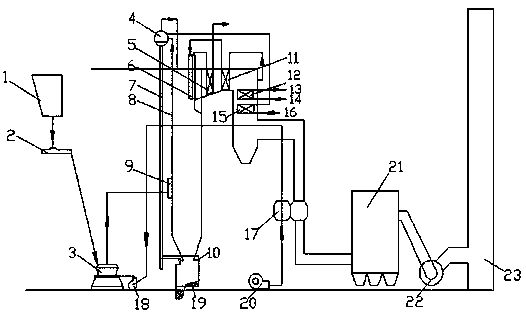

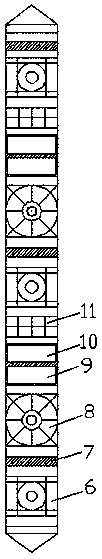

[0032] Examples of the invention are Figure 4 As shown, the combustor of the power plant boiler adopts the technology of impinging flow, four nozzles, primary air opposing impingement and double secondary quadrangular tangential arrangement.

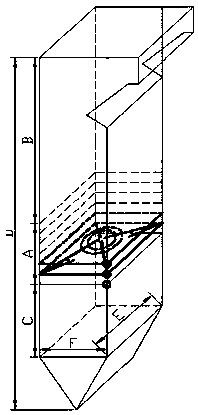

[0033] figure 2 and image 3 As shown, the specific method is as follows: the primary air flow type 3 of the four nozzles of the impingement flow is located in the center of the furnace, and the impact area is located in the center of the furnace. Using the four-corner tangential combustion technology, two imaginary tangent circles with the same rotation direction and different diameters are formed in the center of the furnace, and the smaller diameter tangent circles are close to the impact area.

[0034] figure 2As shown, the outlet jet centerline of the primary air nozzle and the water wall centerline form an upward angle (the angle is small), so the four nozzles collide against each other with a certain upward inclination angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com