Milk fat determination system

A measurement system, milk fat technology, applied in the direction of analysis of materials, instruments, etc., can solve the problems of poor repeatability and accuracy, large influence of human factors, high test failure rate, etc., achieve operational specifications, reduce the influence of human factors, test high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

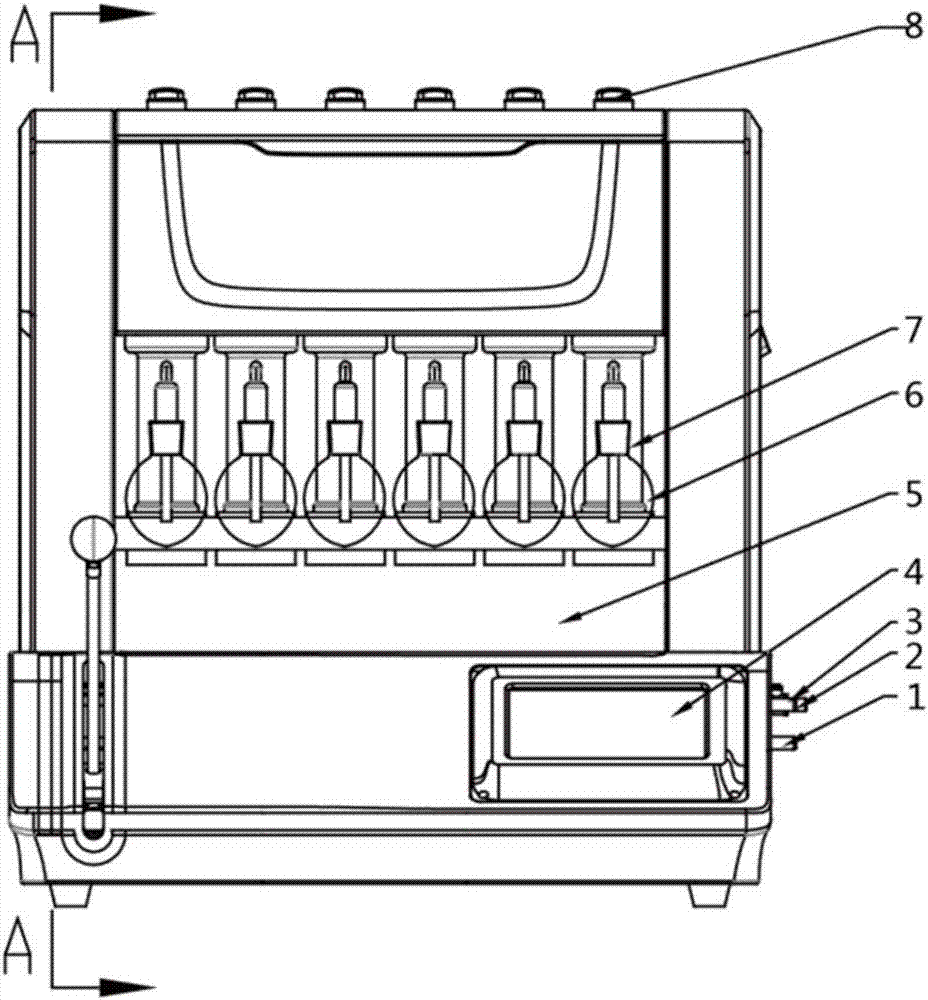

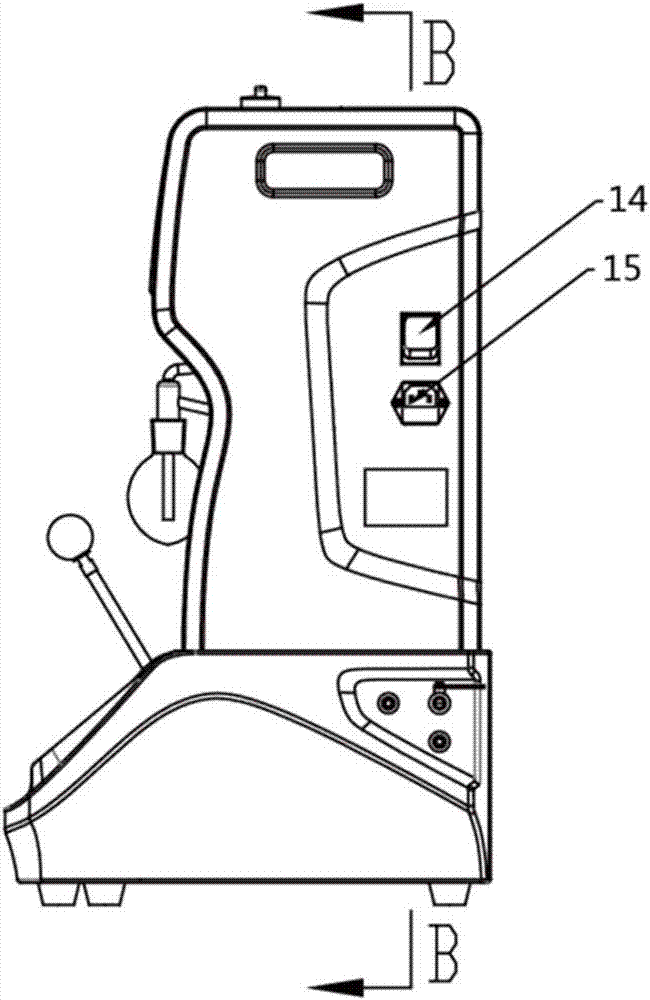

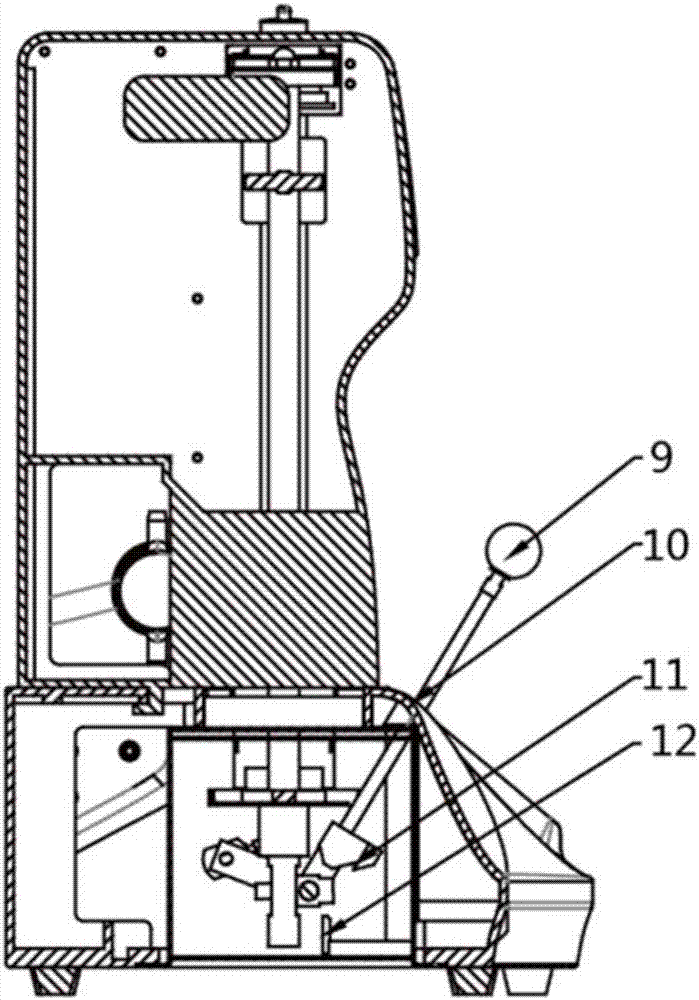

[0022] refer to Figure 1-8 , a kind of milk fat measuring system proposed by the present invention, comprises a stirring device, a chiller and a milk fat measuring instrument arranged in sequence, and the milk fat measuring instrument includes a first body and a second body arranged at the lower end of the first body, so The first body and the second body are integrally formed, and the side wall of the second body is provided with a water outlet 1, a liquid discharge port 2 and a water inlet 3, and the liquid discharge port 2 and the water inlet 3 are located on the same horizontal plane. The water outlet 1 is located directly below the liquid discharge port 2, and the front side of the second body is provided with a lifting rod 10 and a display screen 4 sequentially along the horizontal direction, and the upper end of the lifting rod 10 is provided with a lifting handle 9. The lower end of the lifting rod 10 runs through the second body and extends to the inside of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com