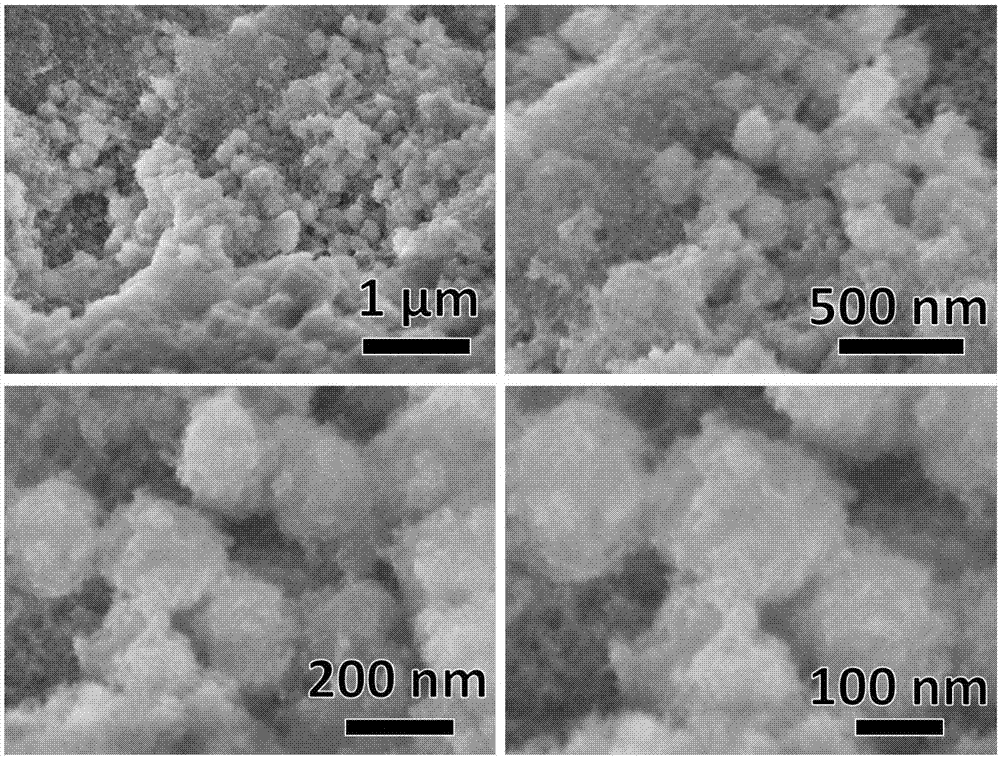

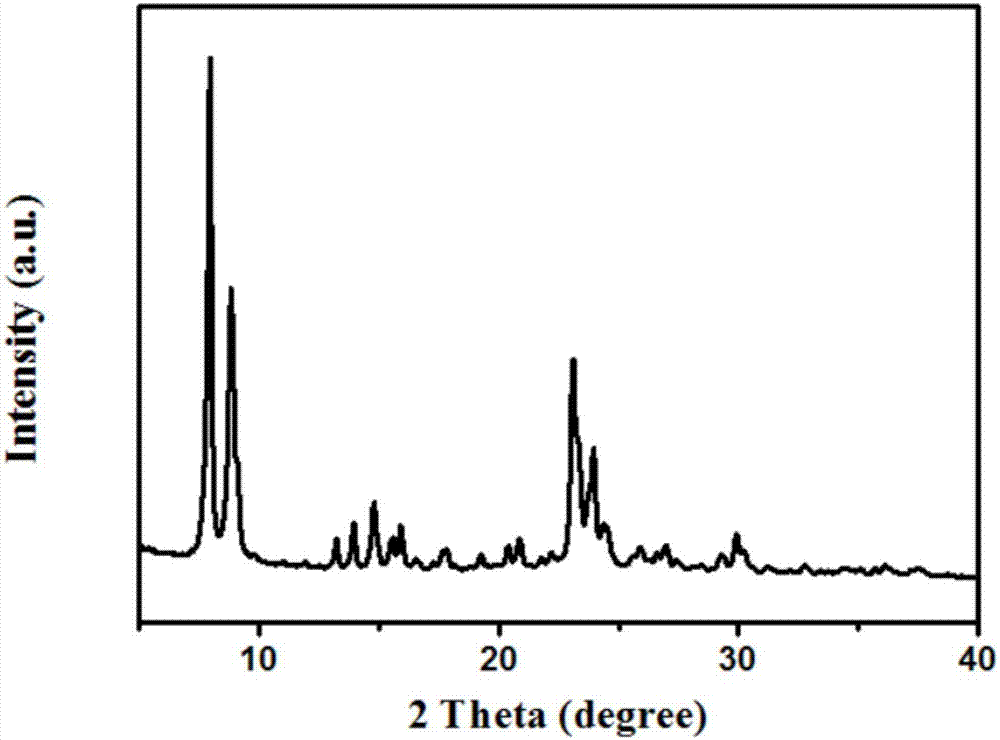

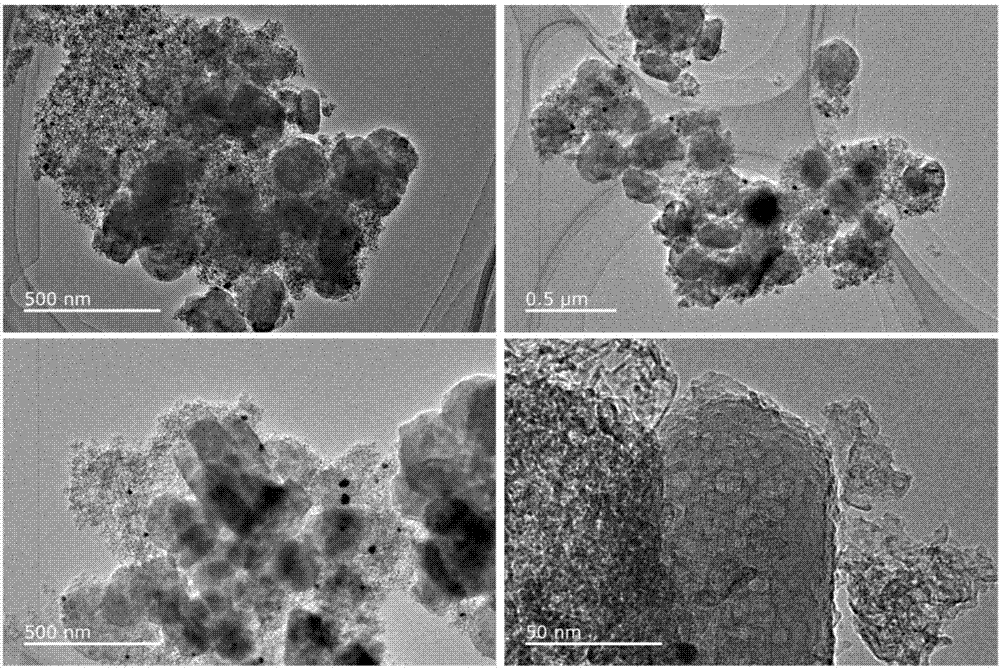

Wormlike mesoporous Al2O3/molecular sieve composite material and preparation method thereof

A composite material and molecular sieve technology, applied in the field of worm-like mesoporous Al2O3/molecular sieve composite material and its preparation, can solve the problems of complex preparation method, low flow diffusivity of microporous molecular sieve, increased synthesis cost, etc., and achieves broad application prospects, The method is simple, feasible and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A worm-like mesoporous Al 2 o 3 / Molecular sieve composite material, its preparation method comprises the steps:

[0035] 1) Synthesis of microporous nano-molecular sieves: 11.4g TPAOH (40wt%) solution and 20g TEOS were added to 30g deionized water successively, stirred for 3h, and allowed to mix uniformly to obtain a clear solution, and the resulting solution was poured into a reaction kettle, Heating to 100°C for crystallization for 24 hours, washing the crystallized product, drying it, and roasting it in a muffle furnace at 550°C for 6 hours to obtain a microporous nanomolecular sieve;

[0036] 2) Add 0.2 g of the obtained microporous nano-molecular sieve to 100 mL of ethanol, and sonicate for 5 hours to obtain a monodisperse uniform mixed solution I;

[0037] 3) Add 2g of aluminum sec-butoxide to 100mL of ethanol, stir for 5min to fully mix to obtain the mixed solution II;

[0038] 4) Slowly add the obtained mixed solution II into the mixed solution I, keep the s...

Embodiment 2

[0042] A worm-like mesoporous Al 2 o 3 / Molecular sieve composite material, its preparation method comprises the steps:

[0043]1) Synthesis of microporous nano-molecular sieves: sequentially add 11g TPAOH (40wt%) solution, 20g silica sol (30wt%) to 16g deionized water, stir for 4h, make it evenly mixed, obtain a clear solution, pour the resulting solution into In a reaction kettle, heat to 110°C for crystallization for 20 hours, wash the crystallized product, dry it, and place it in a muffle furnace at 550°C for 7 hours to obtain a microporous nanomolecular sieve;

[0044] 2) Add 0.2 g of the obtained microporous nano-molecular sieve to 100 mL of ethanol, and sonicate for 6 hours to obtain a monodisperse uniform mixed solution I;

[0045] 3) Add 2g of aluminum sec-butoxide to 100mL of ethanol, stir for 2min to fully mix to obtain the mixed solution II;

[0046] 4) Slowly add the obtained mixed solution II to the mixed solution I, keep the solution I stirring continuously, ...

Embodiment 3

[0050] A worm-like mesoporous Al 2 o 3 / Molecular sieve composite material, its preparation method comprises the steps:

[0051] 1) Synthesis of microporous nano-molecular sieves: 11.4g TPAOH (40wt%) solution, 5.9g white carbon black (i.e. 5.9g nanometer SiO 2 Particles) were added to 50g of deionized water, stirred for 5 hours, and mixed uniformly to obtain a clear solution. The resulting solution was poured into a reaction kettle, heated to 100°C for 24 hours to crystallize, and the crystallized product was washed and dried. Place it in a muffle furnace at 550°C for 6 hours to obtain microporous nanomolecular sieves;

[0052] 2) Add 0.2 g of the obtained microporous nano-molecular sieve to 100 mL of ethanol, and sonicate for 5 hours to obtain a monodisperse uniform mixed solution I;

[0053] 3) Add 1.5g of aluminum sec-butoxide to 80mL of ethanol, stir for 3 minutes to mix thoroughly, and obtain the mixed solution II;

[0054] 4) Slowly add the obtained mixed solution II...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Micropore specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com