Glass manufacture device and manufacture method for high-transmittance optical glass

A glass manufacturing and glass liquid technology, applied in the field of glass manufacturing, can solve problems such as affecting production and electrode corrosion, and achieve the effects of prolonging service life, reducing corrosion, and not easy to oxidize and corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The composition of an optical glass is as follows, in mass percentage: SiO 2 : 30%, BaO: 20%, TiO 2 : 15%, Nb 2 o 5 : 15%, Na 2 O: 13%, CaO: 3%, ZrO 2 : 3%, Sb 2 o 3 : 1%, the refractive index is 1.84444, the Abbe dispersion coefficient is 23.90, and the 400nm transmittance is 0.74.

[0051] The process of making above-mentioned optical glass by the inventive method is as follows:

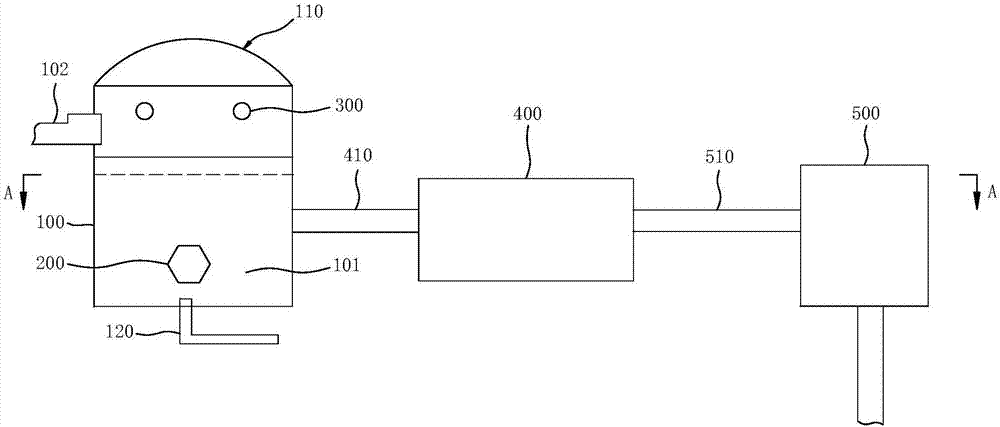

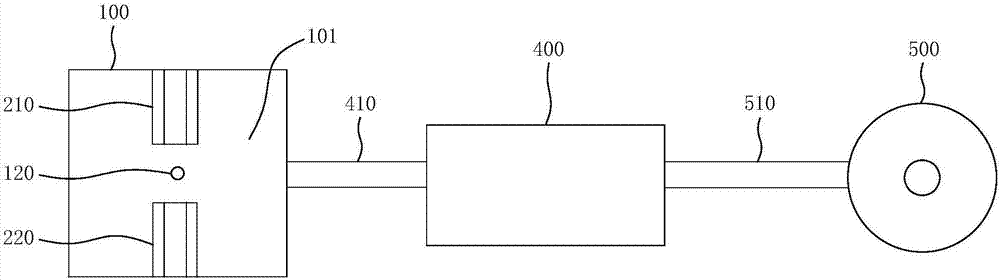

[0052] The glass manufacturing device with the following structure is used for manufacturing, and the glass manufacturing device includes a melting tank 100, an electrode 200, a clarifying tank 400 and a discharge tank 500;

[0053] The melting pool 100 is provided with a melting chamber 101 for melting glass raw materials into molten glass, and the melting pool 100 is provided with a feeding part 102 communicating with the melting chamber 101; the top of the melting pool 100 is provided with a melting pool Cover 110, the bottom of the melting pool 100 is provided with an air injecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com