Paint special for wickerwork and preparation method of paint

A technology of willow weaving and deionized water, which is applied to paints, coatings, anti-fouling/underwater coatings containing biocide, etc. It can solve the problems of service life of willow products that are susceptible to corrosion, poor paint spraying effect, and paint peeling off. , to achieve the effect of natural color, strong adhesion and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

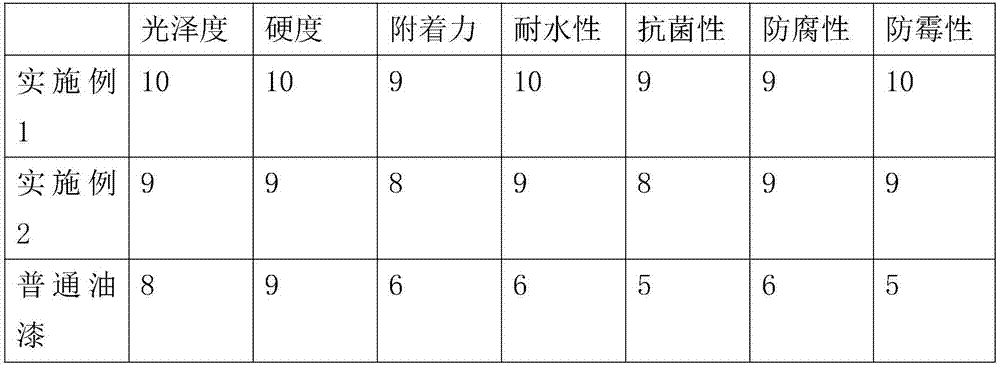

Examples

Embodiment 1

[0015] Get each raw material by weight as follows: 60 parts of deionized water, 38 parts of polyketone resin, 28 parts of dammar resin, 22 parts of maleic acid resin, 23 parts of chlorinated polypropylene resin, 25 parts of glycerin, 7 parts of polyvinyl alcohol , 4 parts of α-cyanoacrylate, 4 parts of stearic acid, 4 parts of magnesium hydroxide, 17 parts of titanium dioxide, 3 parts of antibacterial and antifungal liquid, 0.8 parts of dispersant, 0.6 parts of defoamer, and 1 part of thickener .

[0016] First add deionized water, polyketone resin, dammar resin, maleic acid resin, chlorinated polypropylene resin, glycerin, polyvinyl alcohol, α-cyanoacrylate, stearic acid and dispersant into the container Heat to 80-85 degrees Celsius, stir at 500-600 rpm for 10-15 minutes; then add the formula amount of magnesium hydroxide, titanium dioxide, defoamer and thickener, keep the temperature at 70-75 degrees Celsius, continue Stir at a speed of 500-600 rpm for 10-15 minutes; final...

Embodiment 2

[0018] Get each raw material by weight as follows: 70 parts of deionized water, 40 parts of polyketone resin, 30 parts of dammar resin, 20 parts of maleic acid resin, 23 parts of chlorinated polypropylene resin, 25 parts of glycerin, 6 parts of polyvinyl alcohol , 3.5 parts of α-cyanoacrylate, 4.5 parts of stearic acid, 4 parts of magnesium hydroxide, 18 parts of titanium dioxide, 4 parts of antibacterial and antifungal liquid, 0.5 part of dispersant, 0.5 part of defoamer, 0.5 part of thickener .

[0019] First add deionized water, polyketone resin, dammar resin, maleic acid resin, chlorinated polypropylene resin, glycerin, polyvinyl alcohol, α-cyanoacrylate, stearic acid and dispersant into the container Heat to 80-85 degrees Celsius, stir at 500-600 rpm for 10-15 minutes; then add the formula amount of magnesium hydroxide, titanium dioxide, defoamer and thickener, keep the temperature at 70-75 degrees Celsius, continue Stir at a speed of 500-600 rpm for 10-15 minutes; final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com