Cremator tail gas multistage incinerator

A cremation furnace and incinerator technology, which is applied in incinerators, combustion methods, combustion types, etc., can solve the problems of dioxin emission hazards and incomplete treatment of dioxins, and achieve the effect of ensuring compliance with emission standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

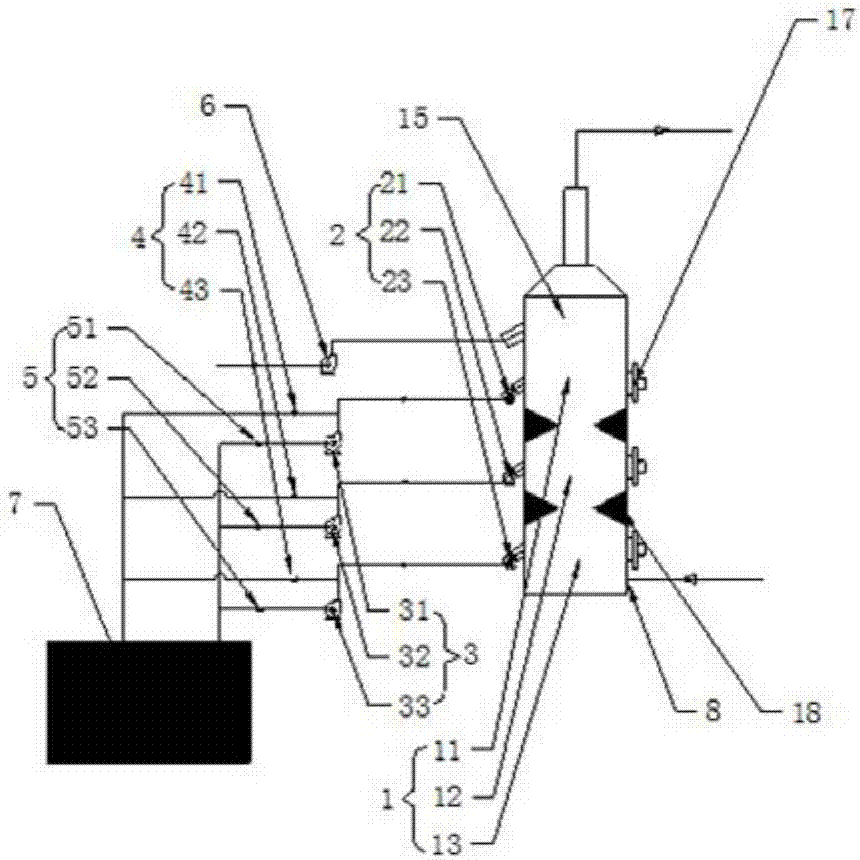

[0015] Such as figure 1 As shown, a multi-stage incinerator for the tail gas of a cremation furnace includes a combustion chamber 1, a burner 2, an oil pump 3, an oil supply pipe 5, an oil return pipe 4, an air mixing fan 6, an oil tank 7, and a tail gas inlet 8. The tail gas The inlet 8 is located at the bottom of the combustion chamber 1, and is characterized in that the oil pumps 3 are the No. 1 oil pump 33, the No. 2 oil pump 32, and the No. 3 oil pump 31 respectively. Each oil pump is connected with an oil supply pipe 5 and an oil return pipe 4. The oil supply pipe 5 and the oil return pipe 4 are connected to the oil tank 7. The burners 2 are respectively a first-stage burner 23, a second-stage burner 22, and a third-stage burner 21, which are connected to the No. 1 oil pump 33, the No. 2 oil pump 32, and the No. 3 oil pump respectively. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap