Non-doped white light luminous layer series organic light-emitting device

An electroluminescent device, non-doped technology, applied in electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of unfavorable device spectral stability, high color rendering index, complex structure, etc., to improve production repeatability and Production efficiency, simplification of the production process, and the effect of facilitating commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

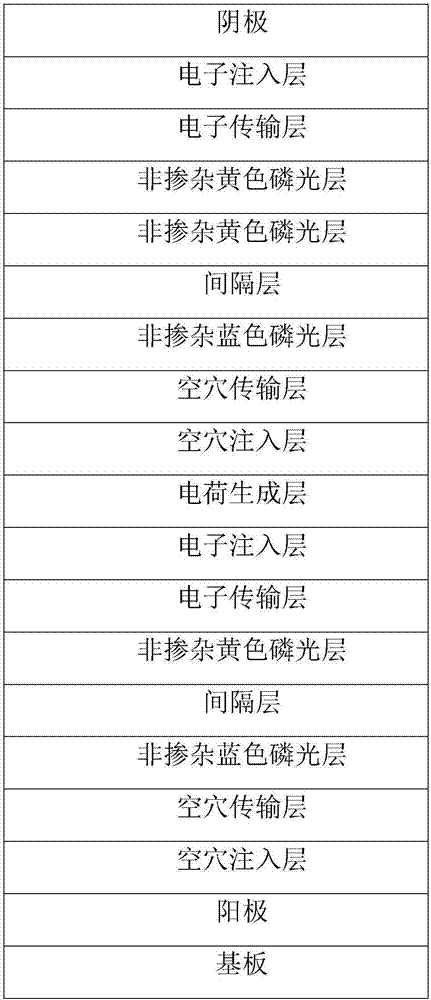

[0029] Such as Figure 1-2 As shown, a non-doped white light emitting layer is connected in series with an organic electroluminescent device. The structure of the device is: ITO / HAT-CN(100nm) / NPB(15nm) / TCTA(5nm) / FIrpic(0.2nm) / TCTA (1nm)Ir(dmppy) 2 (dpp)(0.9nm) / Bepp 2 (15nm) / Bepp 2 :KBH 4 (10nm, 15%) / HAT-CN(120nm) / NPB(15nm) / TCTA(5nm) / FIrpic(0.2nm) / TCTA(1nm)Ir(dmppy) 2 (dpp)(0.9nm) / TmPyPB(50nm) / Cs 2 CO 3 (1nm) / Al(200nm).

[0030] The structure of the device is sequentially superimposed by the following functional layers:

[0031] Substrate, anode, hole injection layer, hole transport layer, undoped blue phosphor layer, spacer layer, undoped yellow phosphor layer, electron transport layer, electron injection layer, charge generation layer, hole injection layer, void Hole transport layer, undoped blue phosphorescent layer, spacer layer, undoped yellow phosphorescent layer, undoped yellow phosphorescent layer, electron transport layer, electron injection layer, cathode.

[0032] The abo...

Embodiment 2

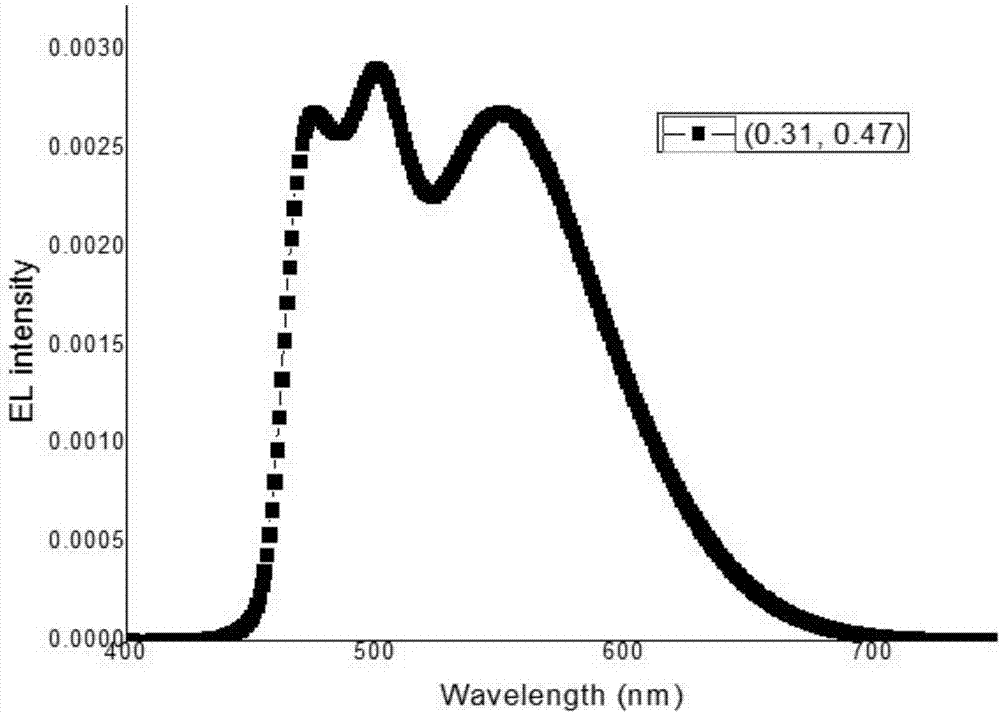

[0070] Such as image 3 As shown, a non-doped white light emitting layer is connected in series with an organic electroluminescent device. The device includes a substrate, an anode, a hole injection layer, a hole transport layer, a non-doped yellow phosphorescent layer, and a non-doped blue from bottom to top. Color phosphorescent layer, electron transport layer, electron injection layer, charge generation layer, hole injection layer, hole transport layer, non-doped yellow phosphor layer, non-doped blue phosphor layer, electron transport layer, electron injection layer and cathode .

[0071] The above-mentioned substrate is glass.

[0072] The above-mentioned anode is an ITO film.

[0073] The above hole injection layer is a 100 nm thick HAT-CN thin film.

[0074] The above hole transport layer includes a first hole transport layer and a second hole transport layer stacked in sequence, the first hole transport layer is a 10nm thick NPB film, and the second hole transport layer is a 1...

Embodiment 3

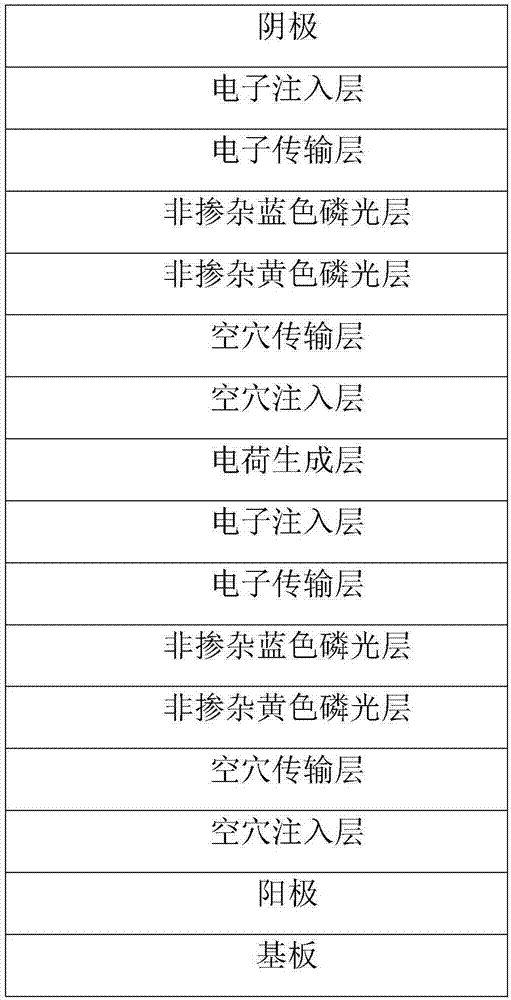

[0087] Such as Figure 4 As shown, a non-doped white light emitting layer is connected in series with an organic electroluminescent device. The device includes a substrate, an anode, a hole injection layer, a hole transport layer, a non-doped yellow phosphorescent layer, a spacer layer, and a non-doped yellow phosphor layer from bottom to top. Doped blue phosphor layer, electron transport layer, electron injection layer, charge generation layer, hole injection layer, hole transport layer, undoped yellow phosphor layer, spacer layer, undoped blue phosphor layer, electron transport layer , Electron injection layer and cathode.

[0088] The above-mentioned substrate is glass.

[0089] The above-mentioned anode is an ITO film.

[0090] The above hole injection layer is a 100 nm thick HAT-CN thin film.

[0091] The above-mentioned hole transport layer includes a first hole transport layer and a second hole transport layer stacked in sequence, the first hole transport layer is a 10 nm thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com