Three-dimensional piezoelectric cantilever beam vibration energy acquisition system

A vibration energy harvesting, three-dimensional piezoelectric technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. , the effect of low structural energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

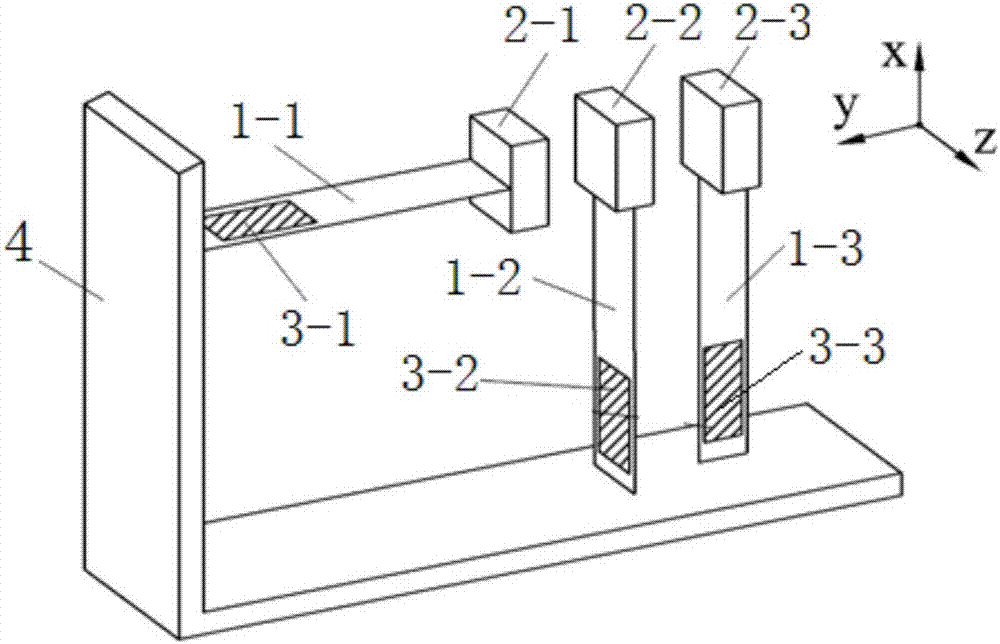

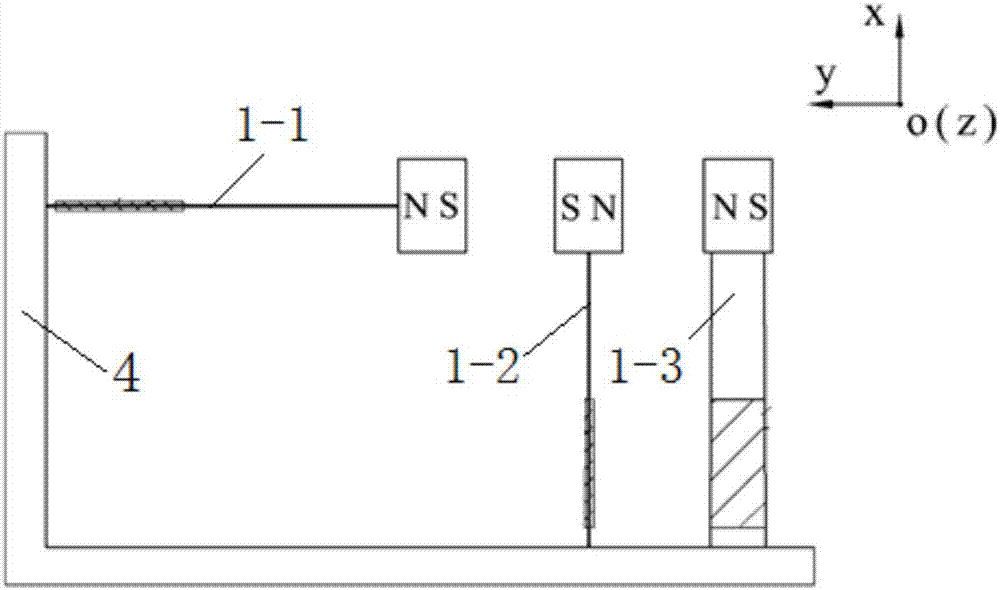

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through embodiments. The three-dimensional piezoelectric cantilever beam vibration energy harvesting system has the following structural features: three cantilever beams are arranged on the right-angle base 4, and the first cantilever beam 1-1 is horizontally fixed on the facade of the right-angle base; the working surface is an up-and-down structure ; The second cantilever beam 1-2 and the third cantilever beam 1-3 are vertically fixed on the horizontal plane of the right-angle base, but the working surfaces of the second and the third cantilever beam are perpendicular to each other (as figure 1 ). A first permanent magnet 2-1, a second permanent magnet 2-2, and a third permanent magnet 2-3 are respectively provided at the free ends of each cantilever beam. The first piezoelectric sheet 3-1, the second piezoelectric sheet 3-2 and the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com