Oil bubble-based column flotation device and method

An oil bubble and column technology, applied in flotation, solid separation, etc., can solve problems such as high oxygen content, waste of coal resources, and poor buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

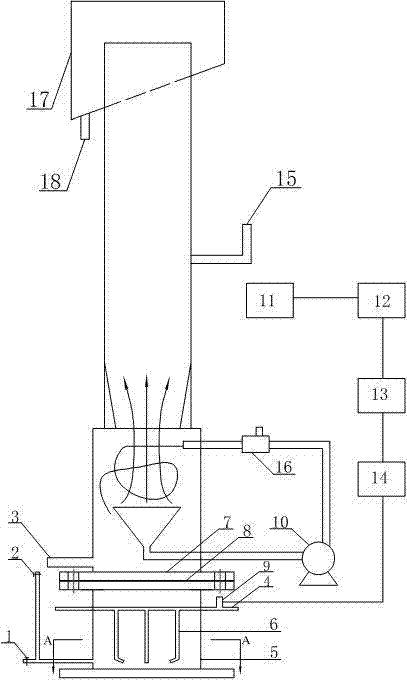

[0012] The present invention will be further described below in conjunction with accompanying drawing:

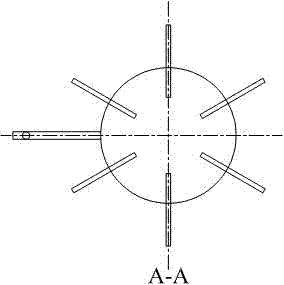

[0013] A column flotation device based on oil bubbles, including an oil inlet valve 2, an oil discharge valve 1, an oil chamber 5, a sintered plate 8, a flange 7, a main inlet pipe 4, a branch inlet pipe 6, and an air inlet 9. Circulation pump 10, bubble generator 16, tailings port 3, overflow tank 17, concentrate discharge port 18, feed port 15, gas flow meter 14, air compressor 11, gas storage tank 13 and steam-water separation The device 12 is characterized in that the oil chamber 5 is arranged in the column type flotation equipment and is divided into a flotation section, a scavenging section and an oil chamber, the oil chamber is located at the lower part of the scavenging area, and the bottom of the column is fixed in the middle of the flange 7 The sintered plate 8 isolates the oil chamber 5 from the pulp in the flotation column; the gas storage tank 13 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com