Steam flooding additive

An additive, steam flooding technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of narrow application range, limited thermal stability, poor adaptability of steam flooding additives, etc., to improve wetting and penetration ability , the effect of reducing the adhesion work and increasing the wetting contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 70 g of dimer fatty acid, 20 g of emulsifier octylphenol polyoxyethylene ether and 10 g of mutual solvent methanol in sequence in the container, stir on a magnetic stirrer, and compound to obtain a steam flooding additive. The obtained steam flooding additive is light yellow liquid.

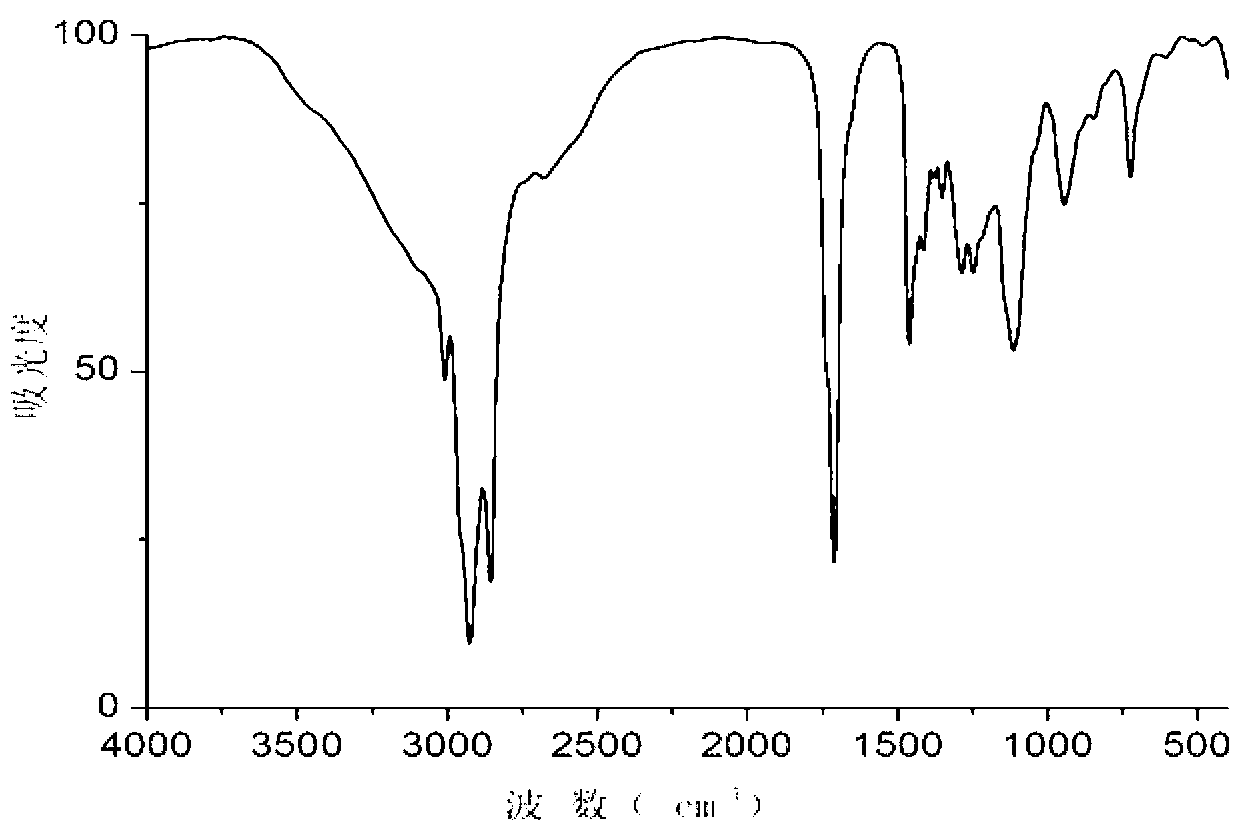

[0017] In order to analyze the composition of the compounded steam flooding additive, its composition and structure can be analyzed by infrared spectroscopy, and the purity of the compounded surfactant can be determined by the method of measuring the acid value. Infrared spectrum such as figure 1 shown. exist figure 1 Medium, 3200~2800cm -1 It is a broad peak, which is the characteristic peak of carboxylic acid; 2921 and 2855cm -1 It is the contraction vibration peak of methyl methylene; 1711cm -1 It is C=O double bond vibration; 1500~1400cm -1 is the bending vibration of methylmethylene; 1112cm -1 It is C-O-C asymmetric stretching vibration of fatty ether. It can be seen from ...

Embodiment 2

[0022] Similar to Example 1, the difference is that 80 g of dimer fatty acid, 15 g of emulsifier nonylphenol polyoxyethylene ether, and 5 g of mutual solvent ethanol are sequentially added in the container.

Embodiment 3

[0024] Similar to Example 1, the difference is that 67g of dimer fatty acid, 25g of emulsifier laurylphenol polyoxyethylene ether and 8g of mutual solvent isobutanol are added sequentially in the container.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com