Amphoteric two-dimensional nanosheet as well as preparation method and application thereof

A two-dimensional nano and amphoteric technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as difficult to meet the requirements of oil displacement operations, the influence of reservoir heterogeneity, and low microscopic oil displacement efficiency. To facilitate large-scale production, improve the displacement effect, and expand the swept volume of water flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

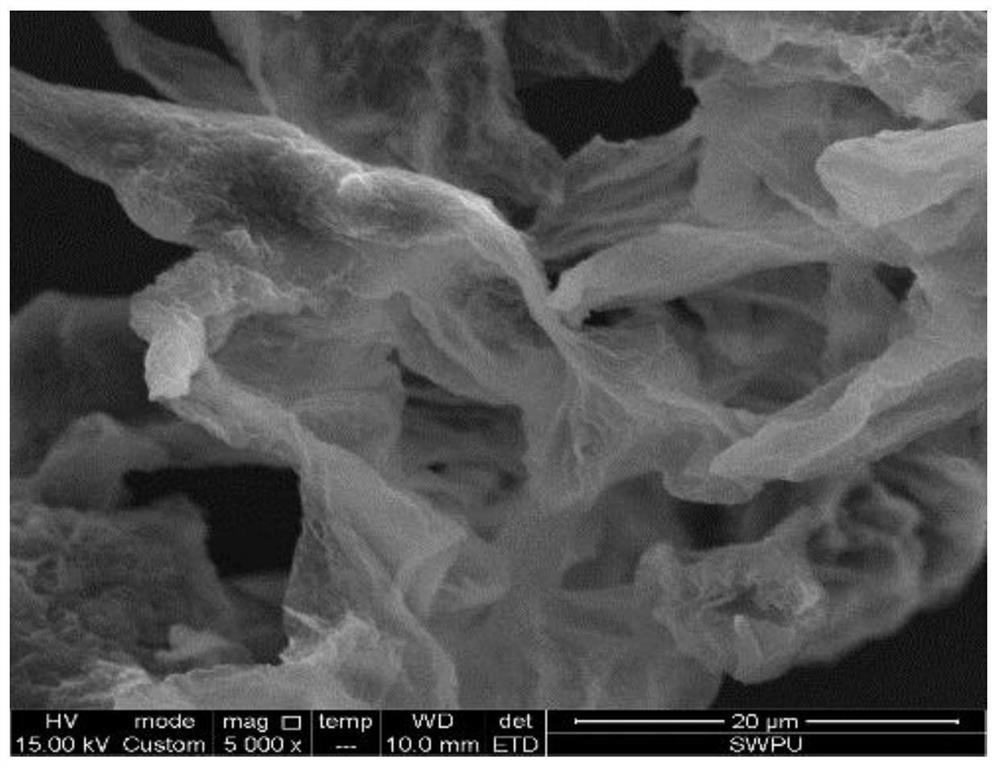

[0033] Add 6g of oligolayer graphite oxide into a 500mL three-necked bottle with a layer thickness of 20nm, then add 40g of toluene, stir in a water bath at 65°C for 60min to ensure that the oligolayer graphite oxide is fully dispersed, and ultrasonicate for 30min; The coupling agent N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane was added to the three-necked bottle dispersed with oligolayer graphite oxide, sealed and stirred, and the combined reaction was carried out in a water bath at 80°C for 4h , suction filtration, purification, and drying to obtain an amino-terminated graphene oxide dispersion;

[0034] Then add 3g of the prepared amine-terminated graphene oxide dispersion in a 500mL three-necked bottle, then add 20g of toluene and dimethylformamide solvent (weight and number ratio 1:1), and stir in a water bath at 80°C 60min; Add 1.2g of tert-butylphenyl glycidyl ether into the three-necked bottle of graphene oxide dispersion dispersed with amine groups at 65°C in ...

Embodiment 2

[0036] Add 8g of oligolayer graphite oxide into a 500mL three-neck flask with a layer thickness of 150nm, then add 50g of toluene, stir in a water bath at 70°C for 60min to ensure that the oligolayer graphite oxide is fully dispersed, and ultrasonicate for 30min; The coupling agent γ-aminopropyltriethoxysilane was added to a three-necked bottle dispersed with oligolayer graphite oxide, sealed and stirred, and combined reaction was carried out in a water bath at 70°C for 4.5 hours, then suction filtered, purified, and dried to obtain an amino-sealed bottle. terminal graphene oxide dispersion;

[0037] Then add 3.5g of the prepared amine-terminated graphene oxide dispersion in a 500mL three-necked bottle, then add 20g of toluene and dimethylformamide solvent (ratio of parts by weight 1:1.2), in a water bath at 80°C Stir for 60 minutes; add 1.5 g of butyl glycidyl ether into a three-necked bottle of graphene oxide dispersion dispersed with amino groups at 80°C in a water bath, se...

Embodiment 3

[0039]Add 9g of oligolayer graphite oxide into a 500mL three-necked bottle with a layer thickness of 400nm, then add 60g of toluene, stir in a water bath at 75°C for 60min to ensure that the oligolayer graphite oxide is fully dispersed, and ultrasonicate for 30min; The coupling agent N-2-(aminoethyl)-3-aminopropyltrimethoxysilane was added to the three-necked bottle dispersed with oligolayer graphite oxide, sealed and stirred, and the combined reaction was carried out in a water bath at 75°C for 5h, and suction filtered , purifying, and drying to obtain an amino-terminated graphene oxide dispersion;

[0040] Then add 4g of the prepared amine-terminated graphene oxide dispersion in a 500mL three-necked bottle, then add 30g of toluene and dimethylformamide solvent (ratio of parts by weight 1:1.3), and stir in a water bath at 85°C 60min; Add 1.8g of octyl glycidyl ether into the three-necked bottle of graphene oxide dispersion dispersed with amino groups at 85°C in a water bath, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com