Processing method of Folium Cylocaryae Paliuri tea

A processing method and technology of willow tea, which is applied in the processing field of paliurus paliurus, can solve the problem that the beneficial components of papaya paliurus cannot be leached well, achieve golden color, meet quality requirements, and increase the effect of leaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

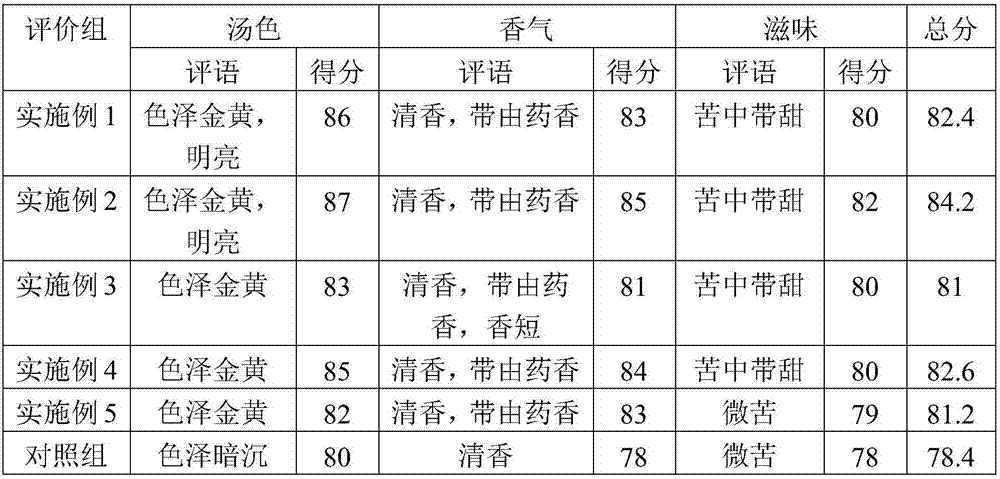

Examples

Embodiment 1

[0028] A processing method of Cyclocarya paliurus tea, comprising the following steps:

[0029] 1) material selection: the fresh leaves taken are the tea raw materials;

[0030] 2) Light irradiation: UV irradiation is carried out on the selected tea leaves;

[0031] 3) drying blue;

[0032] 4) Withering: the tea leaves are spread on the withering tank, the thickness is 9cm, the temperature of the hot air is controlled at 28°C, and the water content of the tea leaves is 75%;

[0033] 5) Shaking green: Shake green leaves after mixing the withered tea leaves and additives at a mass ratio of 30:1. The first shake green vibration frequency is 100r / min, last for 20min, pause for 30min, and the second shake green vibration frequency is 200r / min, last for 10 minutes, pause for 60 minutes;

[0034] 6) Finishing: including pressurization and decompression, the tea leaves are depressurized immediately after finishing under high temperature and high pressure;

[0035] 7) Spreading to...

Embodiment 2

[0047] A processing method of Cyclocarya paliurus tea, comprising the following steps:

[0048] 1) material selection: the fresh leaves taken are the tea raw materials;

[0049] 2) Light irradiation: UV irradiation is carried out on the selected tea leaves;

[0050] 3) drying blue;

[0051] 4) Withering: the tea leaves are spread on the withering trough with a thickness of 11cm, the temperature of the hot air is controlled at 299°C, and the water content of the tea leaves is 76%;

[0052] 5) Shaking green: Shake green leaves after mixing the withered tea leaves and additives at a mass ratio of 35:1. The first shake green vibration frequency is 110r / min, last for 22min, pause for 35min, and the second shake green vibration frequency is 220r / min, last for 12 minutes, pause for 62 minutes;

[0053] 6) Finishing: including pressurization and decompression, the tea leaves are depressurized immediately after finishing under high temperature and high pressure;

[0054] 7) Spread...

Embodiment 3

[0066] A processing method of Cyclocarya paliurus tea, comprising the following steps:

[0067] 1) material selection: fresh leaves are taken as tea raw materials;

[0068] 2) Light irradiation: UV irradiation is carried out on the selected tea leaves;

[0069] 3) drying blue;

[0070] 4) Withering: the tea leaves are spread on the withering tank, the thickness is 12cm, the temperature of the hot air is controlled at 299°C, and the water content of the tea leaves is 77%;

[0071] 5) Shaking green: Shake green leaves after mixing the withered tea leaves and additives at a mass ratio of 40:1. The first shake green vibration frequency is 120r / min, last for 24min, pause for 38min, and the second shake green vibration frequency is 240r / min, last for 14 minutes, pause for 64 minutes;

[0072] 6) Finishing: including pressurization and decompression, the tea leaves are depressurized immediately after finishing under high temperature and high pressure;

[0073] 7) Spreading to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com