Preparation method of TiO2/porphyrin/MOFs (metal-organic frameworks) ultra-thin heteroplasmon

A heterogeneous and porphyrin technology, which is applied in the field of preparation of inorganic-organic composite functional materials, can solve problems such as narrow spectral response range and poor carbon dioxide capture ability, and achieve the effect of optimizing comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) TiO 2 Preparation of nanosheets

[0027] Put 25 mL of tetrabutyl titanate in a beaker, slowly add 5 mL of hydrofluoric acid into the beaker, stir evenly, transfer the obtained white jelly to a 100 ml polytetrafluoroethylene autoclave, and then The reactor is placed at 200 o After reacting for 20 h in a C oven, it was slowly cooled to room temperature. Remove the white precipitate from the lower layer and centrifuge and wash it several times with deionized water until the supernatant is neutral, then place it at 80 o C drying in a vacuum drying oven to obtain TiO 2 Nanosheets.

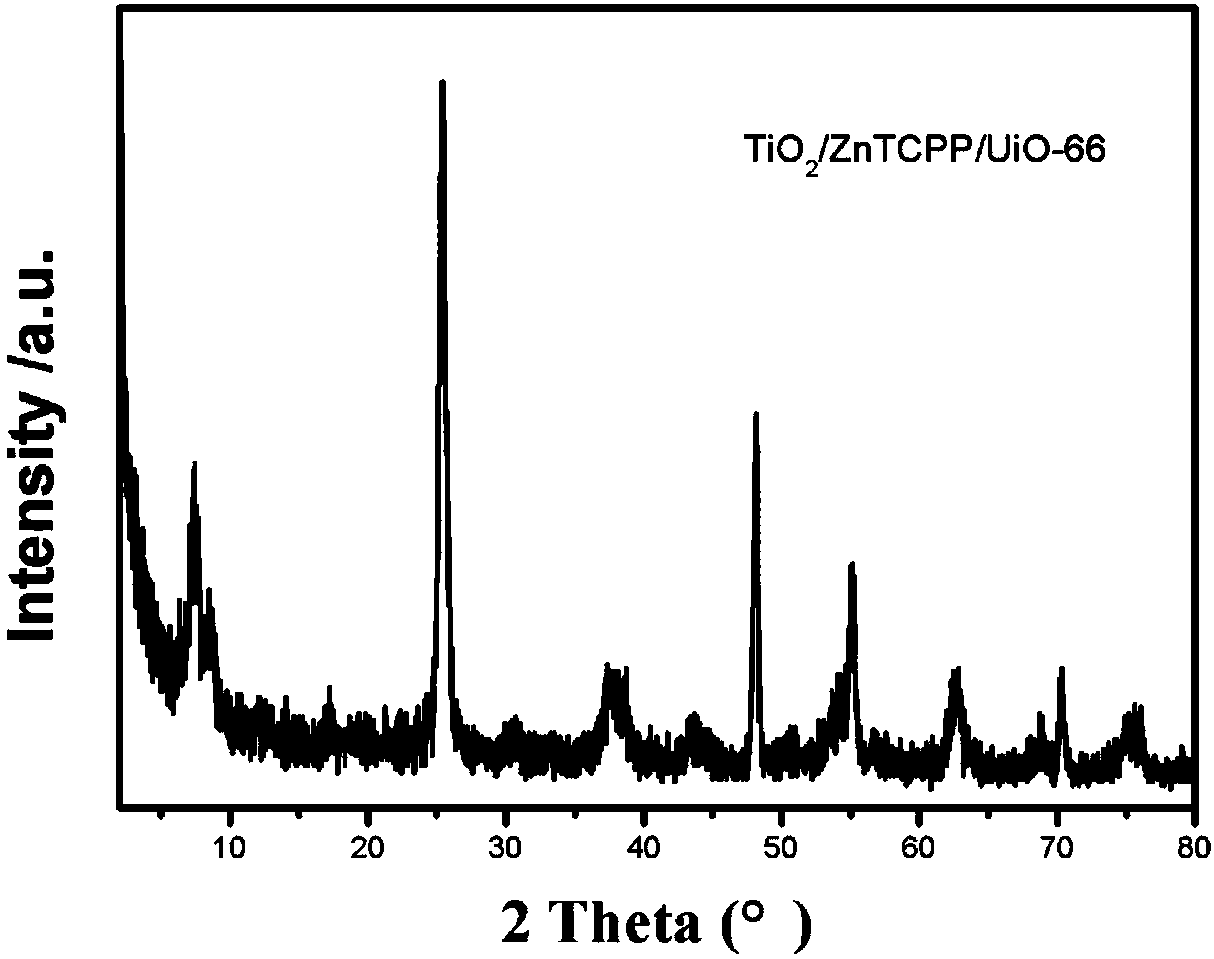

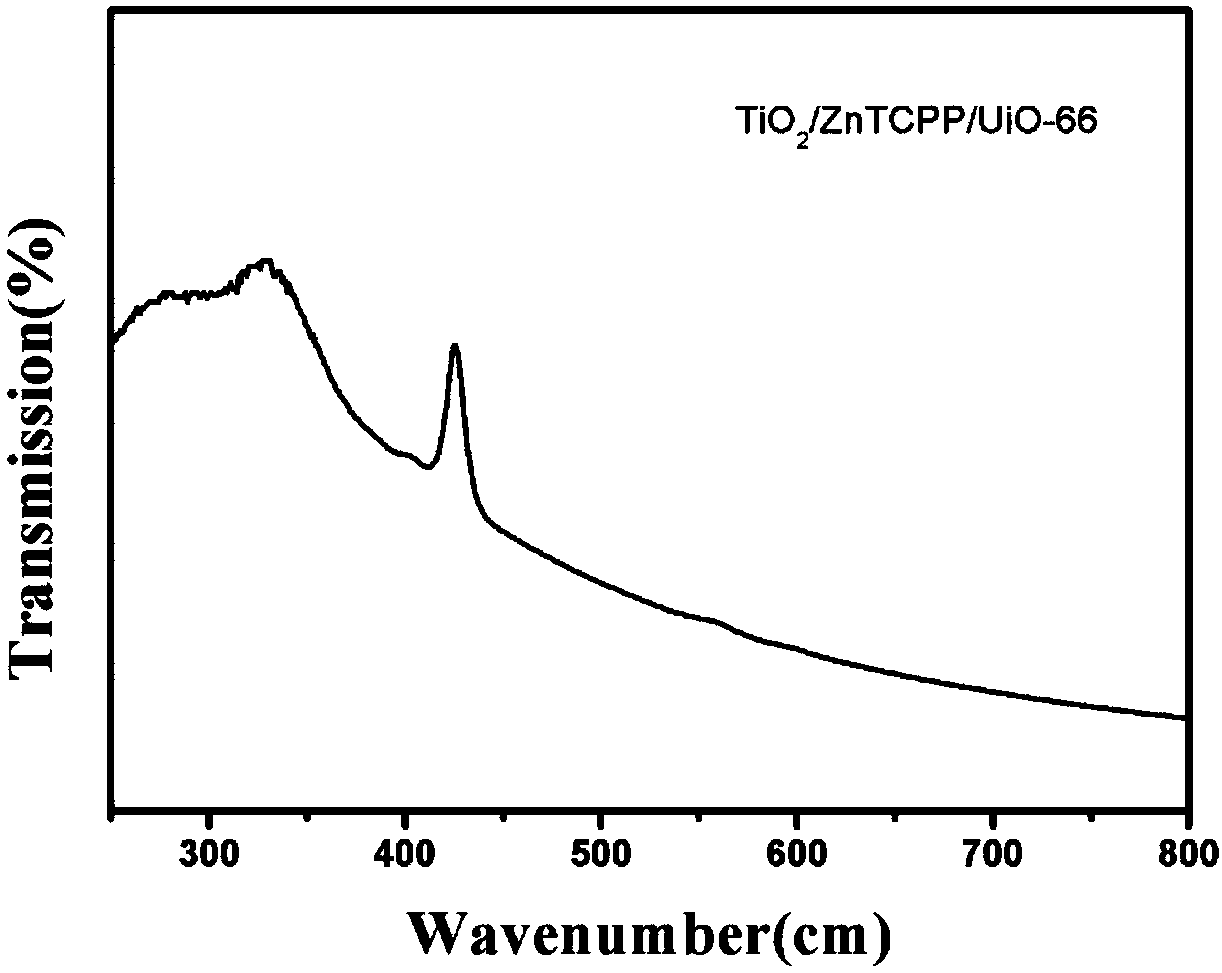

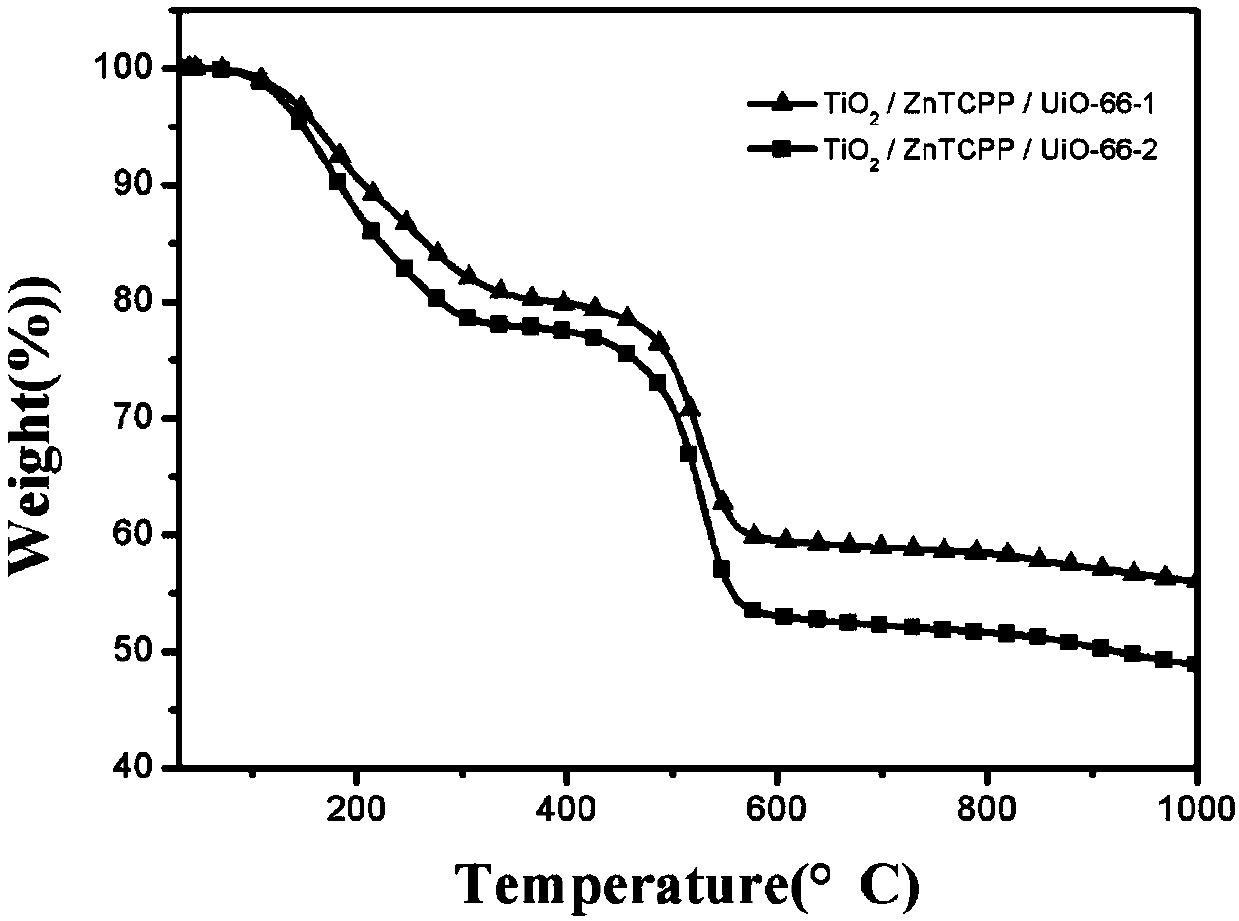

[0028] 2) TiO 2 / Preparation of porphyrin / MOFs

[0029] TiO 2 / Porphyrin / MOFs preparation process is as follows: Take the above TiO 2 Nanosheets 0.1g were placed in a DMF solution of tetracarboxyphenyl cobalt porphyrin with a concentration of 1 M, and placed in an ultrasonic cleaner for 30 minutes to make the TiO 2 The nanosheets were fully dispersed, followed by magnetic stirring ...

Embodiment 2

[0035] 1) TiO 2 Preparation of nanosheets

[0036] Put 25 mL of tetrabutyl titanate in a beaker, slowly add 3 mL of hydrofluoric acid into the beaker, stir evenly, transfer the obtained white jelly into a 100 ml polytetrafluoroethylene autoclave, and then put the reaction Kettle placed at 180 o After reacting for 20 h in a C oven, it was slowly cooled to room temperature. Remove the white precipitate from the lower layer and centrifuge and wash it several times with deionized water until the supernatant is neutral, then place it at 80 o C drying in a vacuum drying oven to obtain TiO 2 Nanosheets.

[0037] 2) TiO 2 / Preparation of porphyrin / MOFs

[0038] TiO 2 / Porphyrin / MOFs preparation process is as follows: Take the above TiO 2 Nanosheets 0.3g were placed in a DMF solution of tetracarboxyphenyl zinc porphyrin with a concentration of 3M, placed in an ultrasonic cleaner for 30min, and the TiO 2 The nanosheets were fully dispersed, followed by magnetic stirring at r...

Embodiment 3

[0040] 1) TiO 2 Preparation of nanosheets

[0041] Put 25 mL of tetrabutyl titanate in a beaker, slowly add 5 mL of hydrofluoric acid into the beaker, stir evenly, transfer the obtained white jelly into a 100 ml polytetrafluoroethylene autoclave, and then put The reactor is placed at 220 o After reacting for 20 h in a C oven, it was slowly cooled to room temperature. Remove the white precipitate from the lower layer and centrifuge and wash it several times with deionized water until the supernatant is neutral, then place it at 80 o C drying in a vacuum drying oven to obtain TiO 2 Nanosheets.

[0042] 2) TiO 2 / Preparation of porphyrin / MOFs

[0043] TiO 2 / Porphyrin / MOFs preparation process is as follows: Take the above TiO 2 Nanosheets 0.5g were placed in a DMF solution of tetracarboxyphenyl cobalt porphyrin with a concentration of 5M, placed in an ultrasonic cleaner for 40min, and the TiO 2 The nanosheets were fully dispersed, followed by magnetic stirring at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com