Integrated pulverizing and mixing assembly for acid pickling sludge treatment

A technology of mixing components and pickling sludge, which is applied in the integrated processing of crushing and mixing, and the field of integrated crushing and mixing components, can solve the problem of increasing manpower, time and equipment, increasing production and processing costs, and low efficiency of pickling sludge treatment. and other problems, to achieve the effect of easy cleaning and maintenance, saving processing steps, and excellent explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

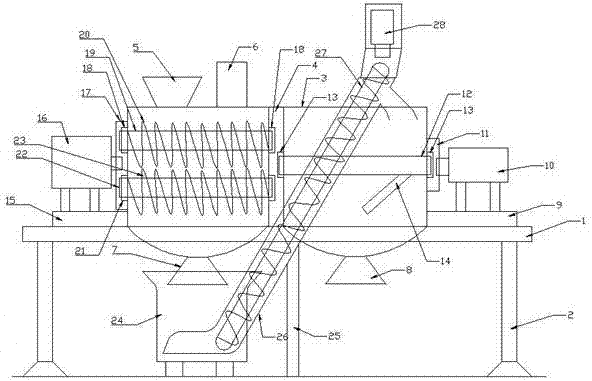

[0013] Such as figure 1 The shown integrated crushing and mixing assembly for pickling sludge treatment consists of a bottom plate 1, a leg 2 arranged under the bottom plate 1, a sealed box 3 set on the bottom plate 1, and a sealed box 3 Partition plate 4, and the feed inlet 5 that is arranged on the sealing box 3, the treatment agent feed opening 6, and the first discharge opening 7, the second discharge opening 8 that are arranged on the sealing box 3 below, and the sealing box is set 3 and located on both sides of the partition 4, the crushing assembly, the mixing assembly, and the conveying assembly used in conjunction with the crushing assembly and the mixing assembly; the crushing assembly includes symmetrically arranged on the sealed box 3 and the partition 4 and cooperate One group of first bearings 18 used, one group of second bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com