Method for simulating dendritic crystal growth of laser welding pool

A simulation method and laser welding technology, applied in laser welding equipment, welding equipment, instruments, etc., can solve problems such as prediction of laser welding molten pool solidification process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

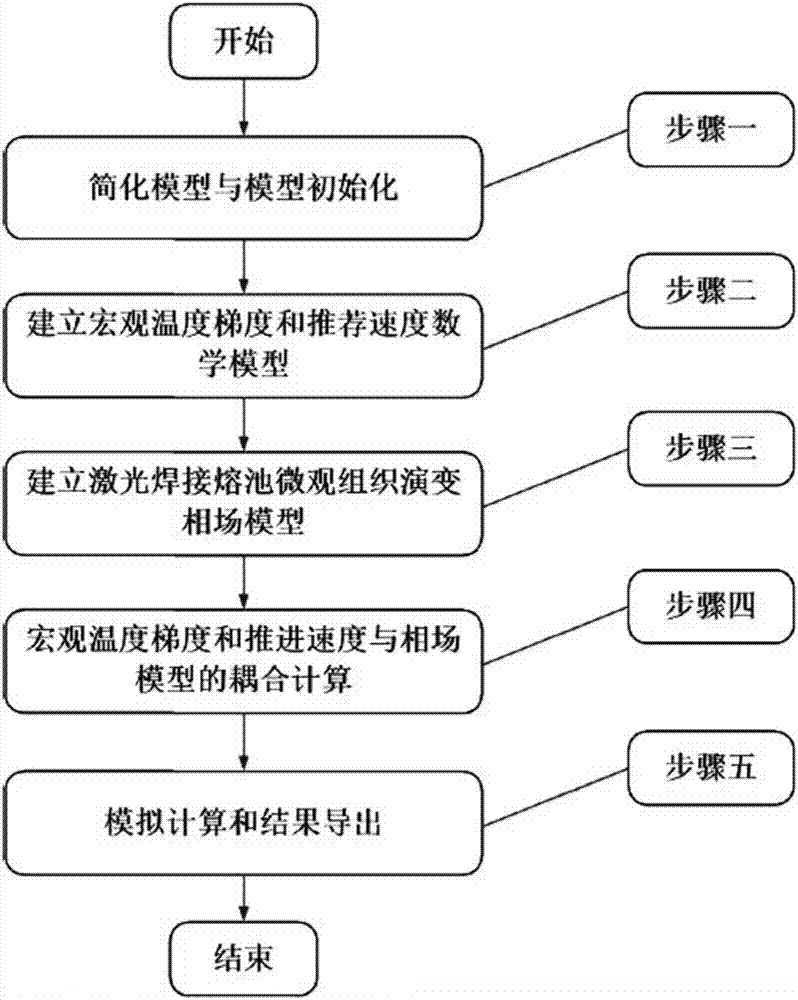

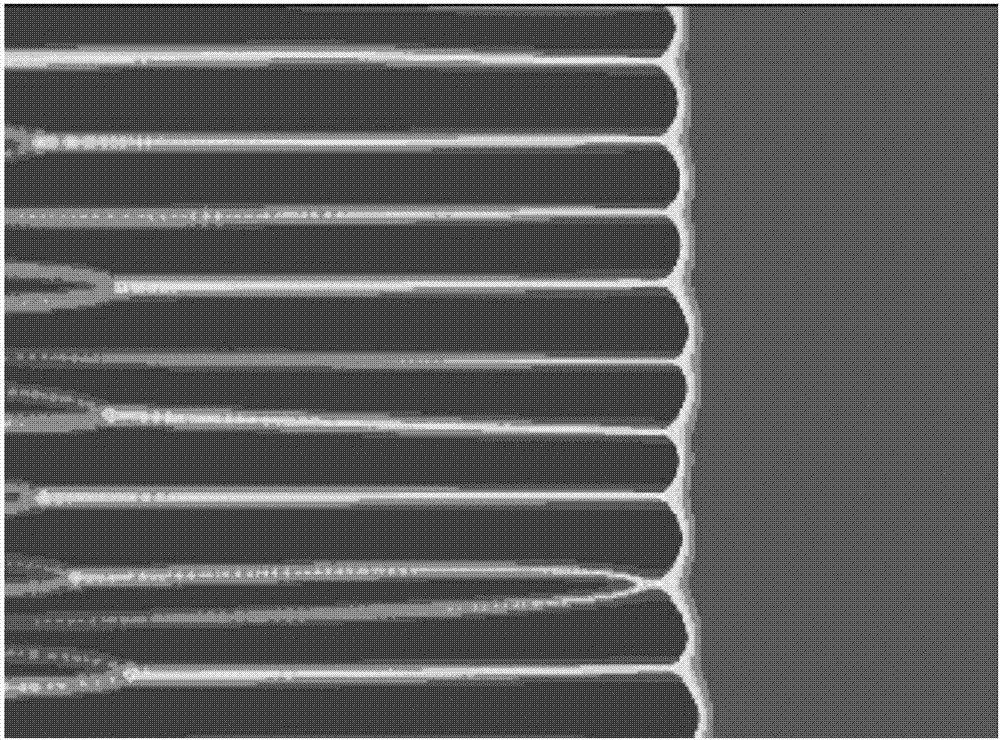

[0052] As shown in the figure, a method for simulating dendritic growth in a laser welding pool of the present invention includes the following steps:

[0053] Step 1: Simplify conditions and model initialization;

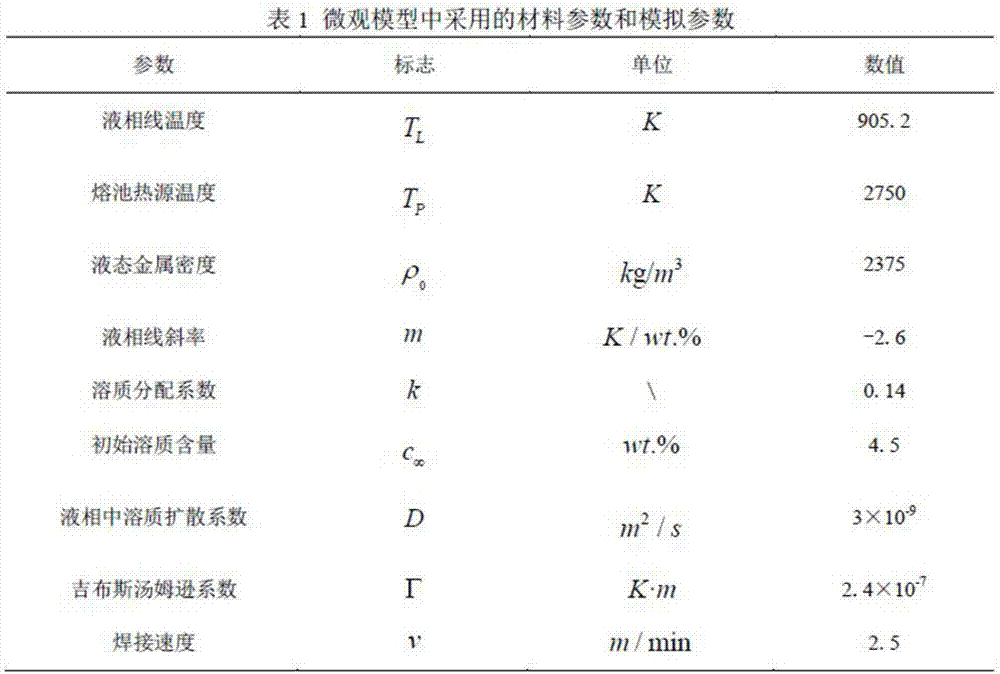

[0054]In order to ensure the computability of the model, some assumptions were made in the process of building the model: cogeneration crystallization will occur at the fusion line of the weld pool, which is equivalent to the directional solidification process, so the initial state of the calculation is assumed to be a planar crystal form. The effect of latent heat on the dendrite growth process was ignored in the simulation calculation. A phase field parameter is introduced, and the change of this para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com