Method of piping continuous production for fatty acid monoethanolamide

A technology of monoethanolamide and fatty acid, which is applied in the field of pipeline continuous production of fatty acid monoethanolamide, achieving the effects of less side reactions, large production capacity and high reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

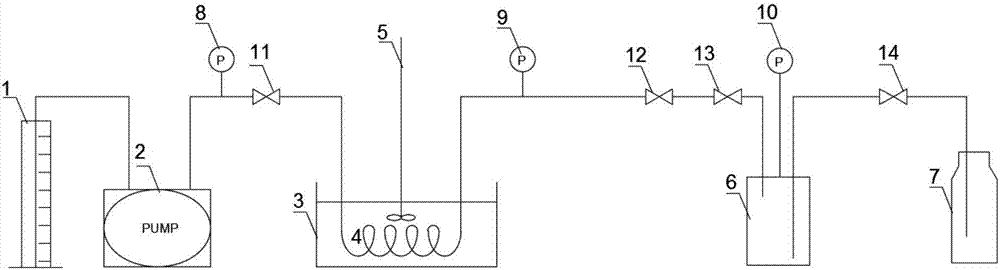

Image

Examples

Embodiment 1

[0065] Embodiment 1, a kind of method of pipeline continuous production fatty acid monoethanolamide, adopts figure 1 The shown device, with methyl laurate and ethanolamine as raw material, carries out the following steps successively:

[0066] 1) Add 300mL of methanol into measuring cylinder 1, fully open the valves (needle valves 11-13, valve 14) in the system, and use a large flow rate of 10mL / min to fill the reaction coil 4 with methanol; Methanol recovery; then add reaction raw material--450mL of methanol solution of methyl laurate and ethanolamine in graduated cylinder 1.

[0067] The methanol solution of methyl laurate and ethanolamine is as follows: firstly methyl laurate and ethanolamine are mixed according to a molar ratio of 1:0.8, and then 1.2 times the volume of methanol is added to dissolve and configure a solution; that is, the volume of methyl laurate and ethanolamine Sum: volume of methanol = 1:1.2.

[0068] 2), charge the internal pressure of the system to 1...

Embodiment 2

[0078] Embodiment 2, a kind of method of pipeline continuous production fatty acid monoethanolamide:

[0079] In step (1), in methanol solution, the mol ratio of methyl laurate and ethanolamine is 1.0:1.0;

[0080] The rest are equal to Example 1.

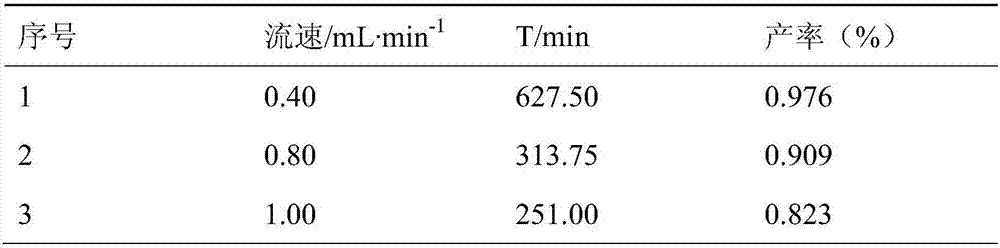

[0081] Under different flow rate conditions, the reaction yields are shown in Table 2 below:

[0082] Table 2, embodiment 2 reaction result

[0083]

[0084]

[0085] The purity of fatty acid monoethanolamide is ≥98%.

Embodiment 3

[0086] Embodiment 3, a kind of method of pipeline continuous production fatty acid monoethanolamide,

[0087] In step (1), in the methanol solution, the molar ratio of methyl laurate and ethanolamine is 1:1.3; then add 1.2 times the volume of methanol to dissolve and configure a solution; that is, the sum of the volumes of methyl laurate and ethanolamine: methanol Volume = 1:1.2;

[0088] The rest are equal to Example 1.

[0089] Under different flow rate conditions, the reaction yields are shown in Table 3 below:

[0090] Table 3, embodiment 3 reaction result

[0091]

[0092] The purity of fatty acid monoethanolamide is ≥98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com