Energy-saving and heat-insulating putty powder and preparation method thereof

A technology of thermal insulation putty and putty powder, applied in the direction of filling slurry, etc., can solve problems such as poor thermal insulation effect and poor waterproof performance, achieve uniform thermal insulation and waterproof performance, prevent delamination and cracking, and improve waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

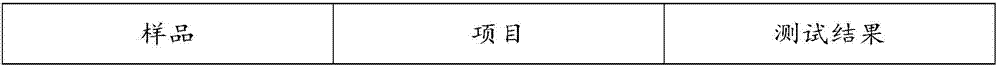

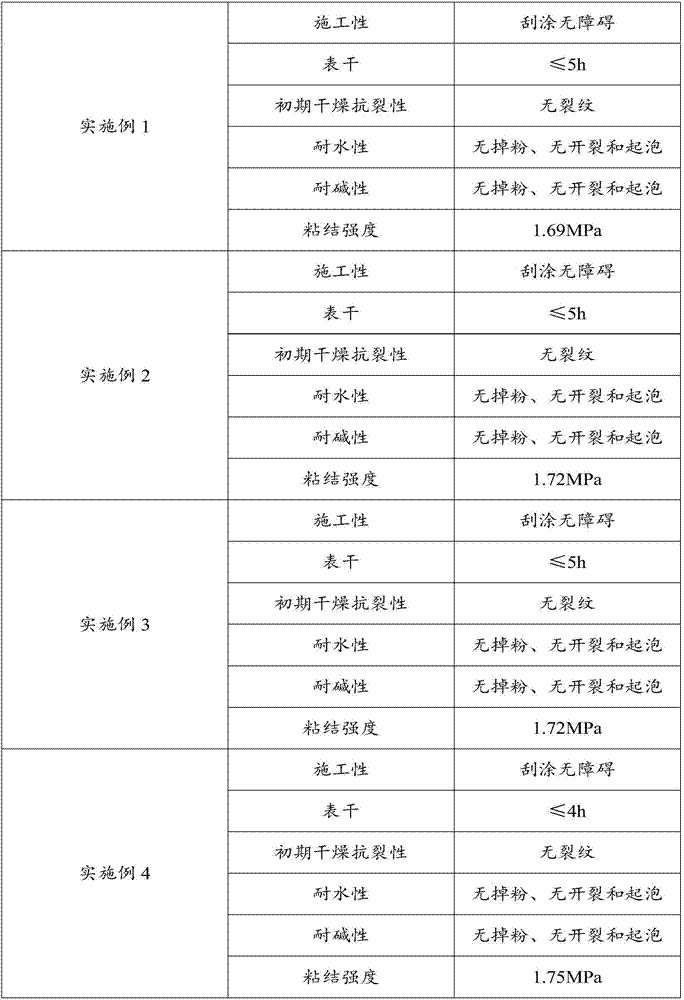

Examples

Embodiment 1

[0048] This embodiment provides an energy-saving and heat-preserving putty powder, which is made of various raw materials. Parts of hollow glass microspheres, 10 parts of polypropylene fiber and 2 parts of mixing aid, wherein the mixing aid includes emulsified silicone oil, and the water-resistant mixing powder includes water-resistant rubber powder.

[0049] This embodiment also provides a method for preparing energy-saving and thermal insulation putty powder, which includes the following steps:

[0050] Firstly, 30 parts of hollow glass microspheres and 10 parts of polypropylene fibers were uniformly mixed at a temperature of 40° C., and then ground to 1000 mesh with 70 parts of talc powder and 100 parts of white cement respectively to obtain the first mixed powder.

[0051] Next, stir and mix the above-mentioned first mixed powder with 20 parts of starch glue and 30 parts of water-resistant blending powder at a temperature of 50-60° C. to obtain a second mixed powder.

[0...

Embodiment 2

[0054] This embodiment provides an energy-saving and heat-preserving putty powder, which is made of various raw materials. Parts of hollow glass microspheres, 20 parts of polypropylene fibers and 10 parts of mixing aids, wherein the mixing aids include polydimethylsiloxane and cyanoacrylate-polyethylene glycol, and polydimethylsiloxane and The mass ratio of cyanoacrylate-polyethylene glycol is 1.5:1; the water-resistant mixing powder includes water-resistant rubber powder and polyurethane, and the mass ratio of water-resistant rubber powder and polyurethane is 2:1.

[0055] This embodiment also provides a method for preparing energy-saving and thermal insulation putty powder, which includes the following steps:

[0056] Firstly, 60 parts of hollow glass microspheres and 20 parts of polypropylene fibers were uniformly mixed at a temperature of 50° C., and then ground to 1200 mesh with 90 parts of talc powder and 200 parts of white cement respectively to obtain the first mixed p...

Embodiment 3

[0060] This embodiment provides an energy-saving and heat-preserving putty powder, which is made of various raw materials. Parts of hollow glass microspheres, 12 parts of polypropylene fibers and 3 parts of mixing aids, wherein the mixing aids include polyoxypropylene glyceryl ether, dibutyltin dilaurate and cyanoacrylate-polyethylene glycol, and polydimethyl The mass ratio of siloxane, dibutyltin dilaurate and cyanoacrylate is 1.5:1:1; the water-resistant mixing powder includes water-resistant rubber powder and polyurethane, and the mass ratio of water-resistant rubber powder and polyurethane is 6:1.

[0061] This embodiment also provides a method for preparing energy-saving and thermal insulation putty powder, which includes the following steps:

[0062] Firstly, 40 parts of hollow glass microspheres and 12 parts of polypropylene fibers were uniformly mixed at a temperature of 45°C, and then ground to 1200 mesh with 75 parts of talc powder and 150 parts of white cement respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com