Photocuring environment-friendly type weather resistance PVD (physical vapor deposition) finishing coat and preparation method and application thereof

An environmentally friendly and weather-resistant technology, applied in the field of coatings, can solve the problems of insufficient comprehensive performance such as environmental pollution, adhesion and weather resistance, and achieve the effect of improving curing speed, enhancing wear resistance and ensuring service life.

Active Publication Date: 2017-11-03

湖南宏泰新材料有限公司

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the serious environmental pollution problem that the coating process represented by water-based chrome plating and the PVD topcoat preparation process based on traditional solvent-based PVD topcoats produce, and the attachment of current UV photocurable PVD topcoats. Focusing on the lack of comprehensive performance such as strength and weather resistance, an environmentally friendly light-curing weather-resistant PVD topcoat is provided, which can be used in fields with high weather resistance requirements, and can meet the needs of light-curing PVD topcoats in mobile phones and automotive lamp reflectors. , ocean engineering and other high-end fields with demanding weather resistance requirements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

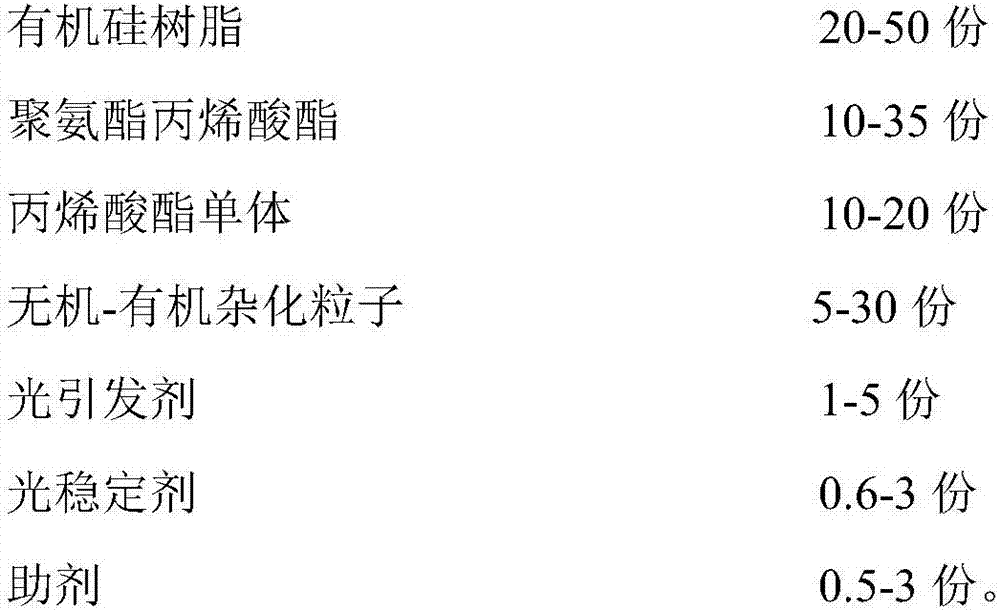

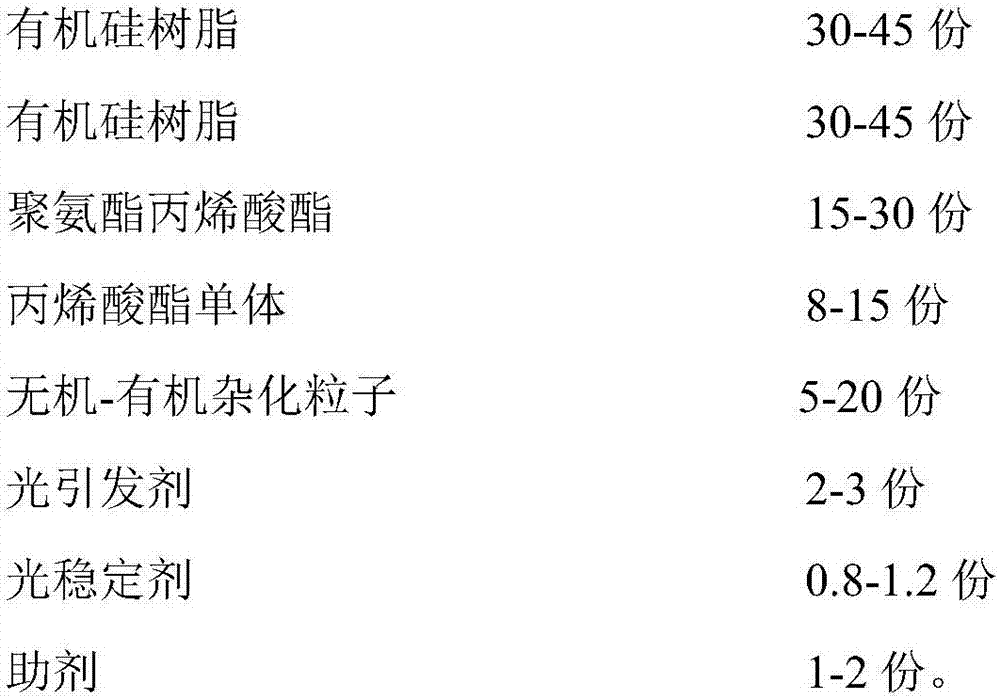

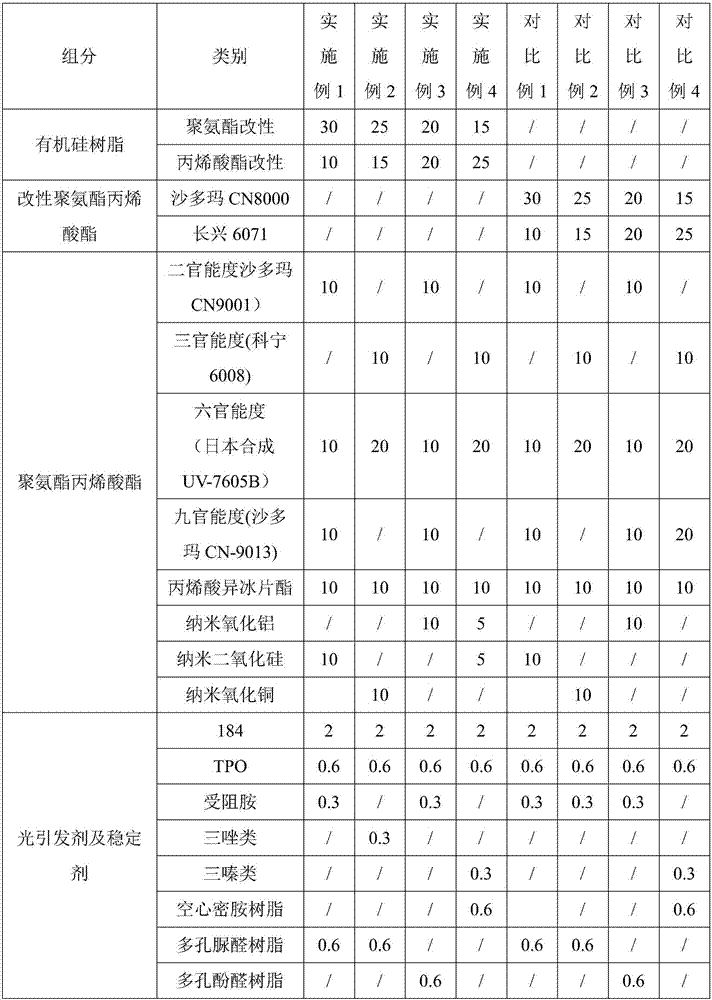

[0035] The components of Examples 1-4 and Comparative Examples 1-4 and their amounts in parts by weight are shown in Table 1.

[0036] Table 1

[0037]

[0038]

[0039] Inorganic-organic hybrid particles can be obtained by sol-gel method, in-situ dispersion polymerization method, intercalation method, blending method and other methods.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses photocuring environment-friendly type weather resistance PVD (physical vapor deposition) finishing coat and a preparation method and application thereof. The finishing coat is prepared from the following ingredients in parts by weight: 20 to 50% of organic silicon resin, 10 to 35% of urethane acrylate, 10 to 20% of acrylate monomer, 5 to 30% of inorganic-organic hybrid particle, 1 to 5% of photoinitiator, 0.6 to 3% of light stabilizer and 0.5 to 3% of additive. Weather resistance of the PVD finishing coat disclosed by the invention is improved from multiple paths. According to the photocuring environment-friendly type weather resistance PVD finishing coat disclosed by the invention, a UV photocuring technology is utilized to solve the problem of serious pollution caused by water chromium plating and a traditional solvent type PVD finishing coat technology. The PVD finishing coat disclosed by the invention can be applied to the fields of mobile phone, automobile metal exterior, marine equipment and the like which have strict requirements for weather resistance.

Description

technical field [0001] The invention relates to the field of coatings, in particular to a light-curing environment-friendly weather-resistant PVD topcoat and its preparation and application. Background technique [0002] Physical vapor deposition (Physical Vapor Deposition, PVD) technology refers to the use of low-voltage, high-current arc discharge technology under vacuum conditions, using gas discharge to evaporate the target material and ionize the evaporated substance and gas, and use the electric field The accelerated action of the vaporized material and its reaction products are deposited on the workpiece. Vacuum coating materials obtained by using PVD technology have both metal texture and light plastic properties. In recent years, they have been widely used in daily-use fields such as 3C products (mobile phones, computers, TVs), automotive lamp reflectors and decorative parts, and cosmetic packaging. application. [0003] In the premise of the application of PVD te...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D183/10C09D183/06C09D175/14C09D7/12

Inventor 陈朝岚吴玉民施扬吴刚强彭叶郭猛刘晓明卢礼灿

Owner 湖南宏泰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com