Dual-curing adhesive and adhesive tape

An adhesive and dual-curing technology, applied in adhesive types, conjugated diene adhesives, polyurea/polyurethane adhesives, etc., can solve the problem of thick and deep curing, good bonding performance, and weather resistance It can achieve the effect of strong bond strength, low yellowing rate and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1~3

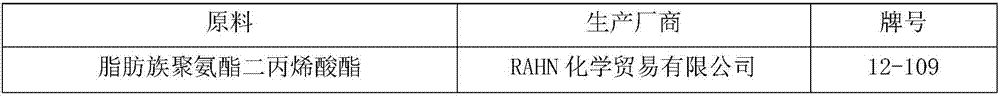

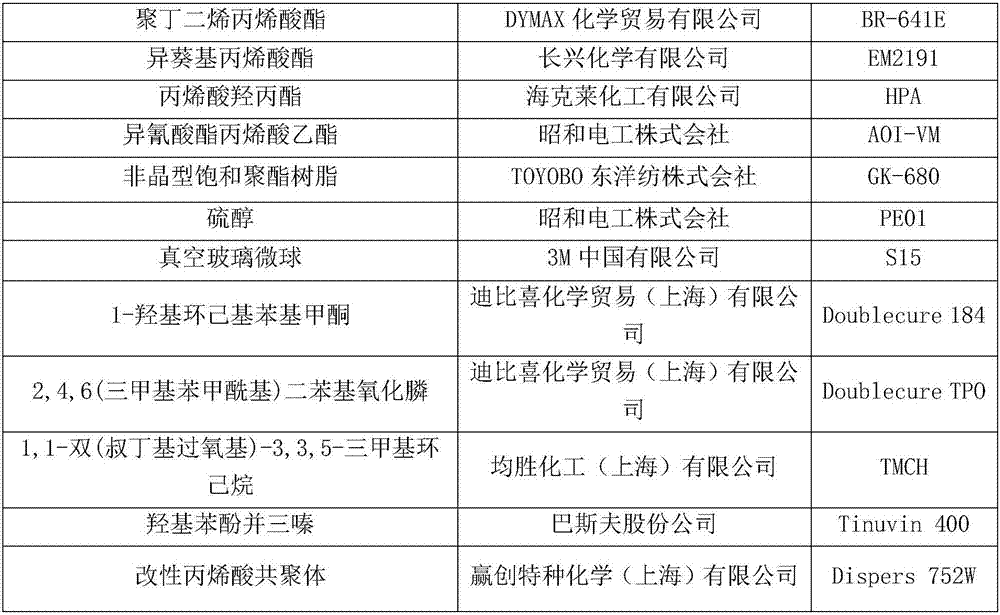

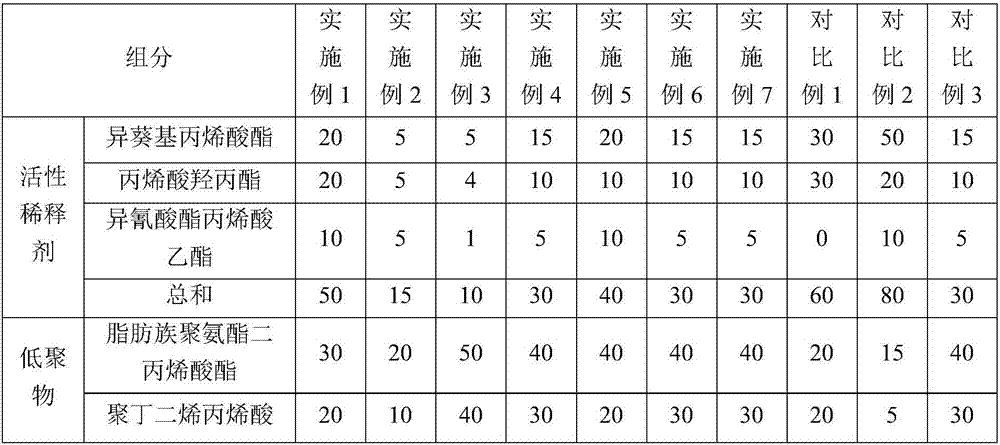

[0044] At normal temperature and pressure, add the reactive diluent into the container according to the components specified in Table 2 and mix evenly; then slowly add oligomers, tackifying resins, mercaptans, vacuum glass micro Stir the ball at the same time to prevent agglomeration until the oligomer and reactive diluent are completely dissolved into a uniform liquid; then add photoinitiator and thermal initiator to the container, heat to 50°C, and stir at the same time until the photoinitiator is completely Dissolve into a uniform liquid; then add ultraviolet absorber and dispersant to the container and continue to stir for 2 hours, after standing still for 1 hour, the sampling test is qualified, and the adhesive of each embodiment and comparative example is made by filtering. During the production process, it is necessary to pay attention to moisture-proof and light-proof.

[0045] Table 2

[0046]

[0047]

[0048] The adhesive properties obtained by the above Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com