SAGD mudstone interlayer jet-fluidic squeeze-acid reforming method

A technology for interlayer and mudstone, applied in the field of oil and gas field development, can solve the problem that the shallow oil sand is difficult to achieve acid liquid flowback, etc., and achieves the improvement of circulation preheating effect, porosity and uniformity, and ultimate recovery factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

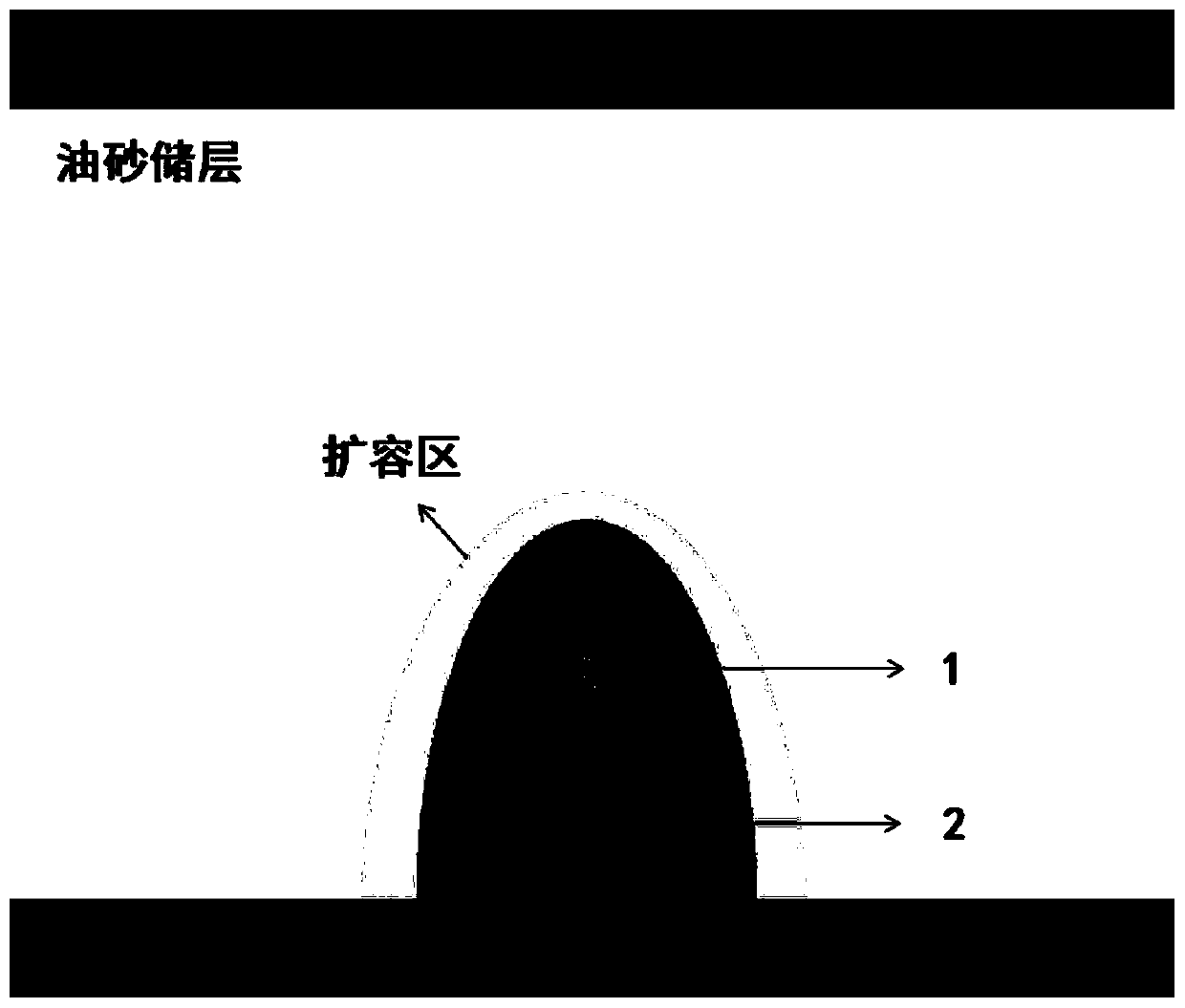

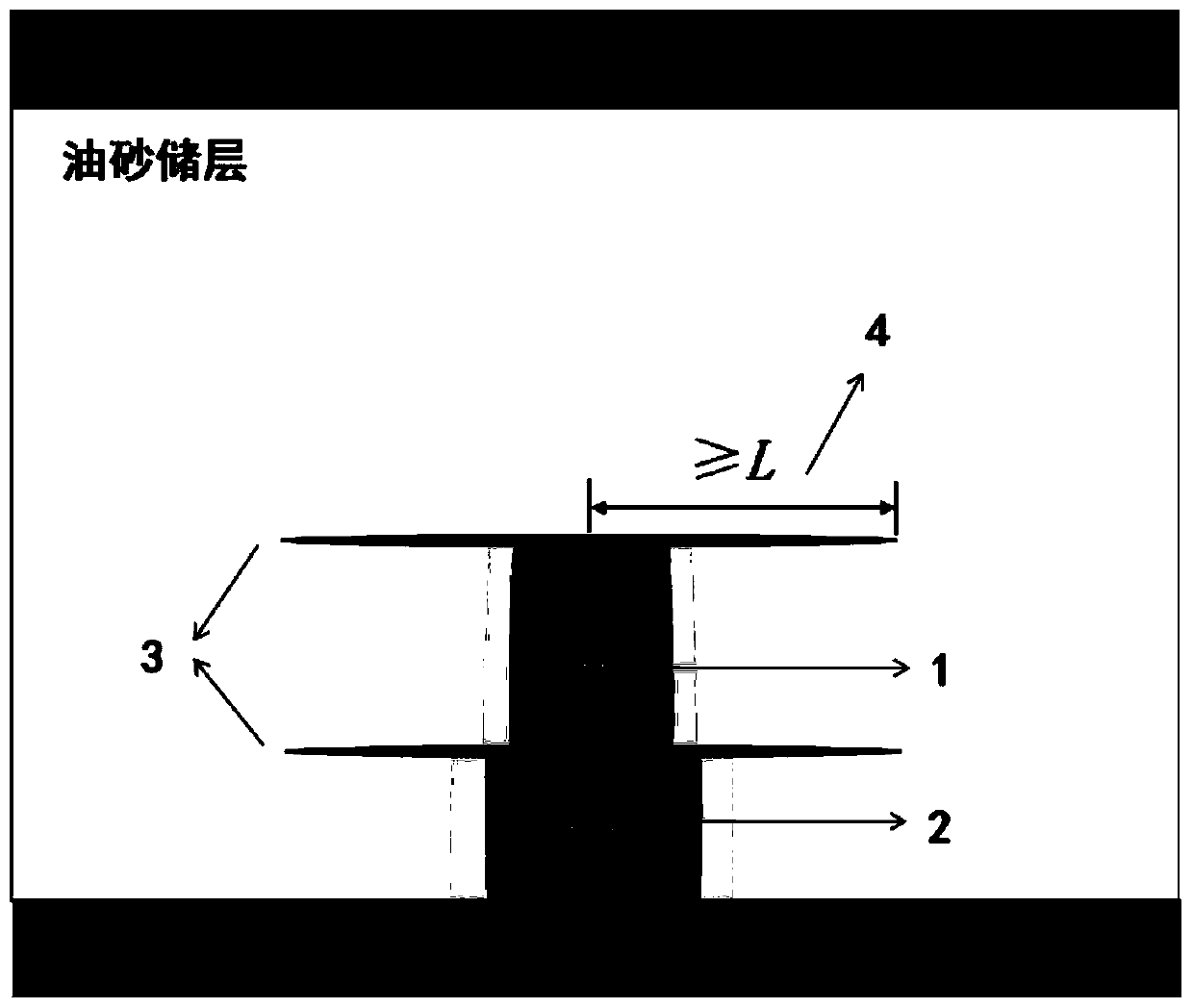

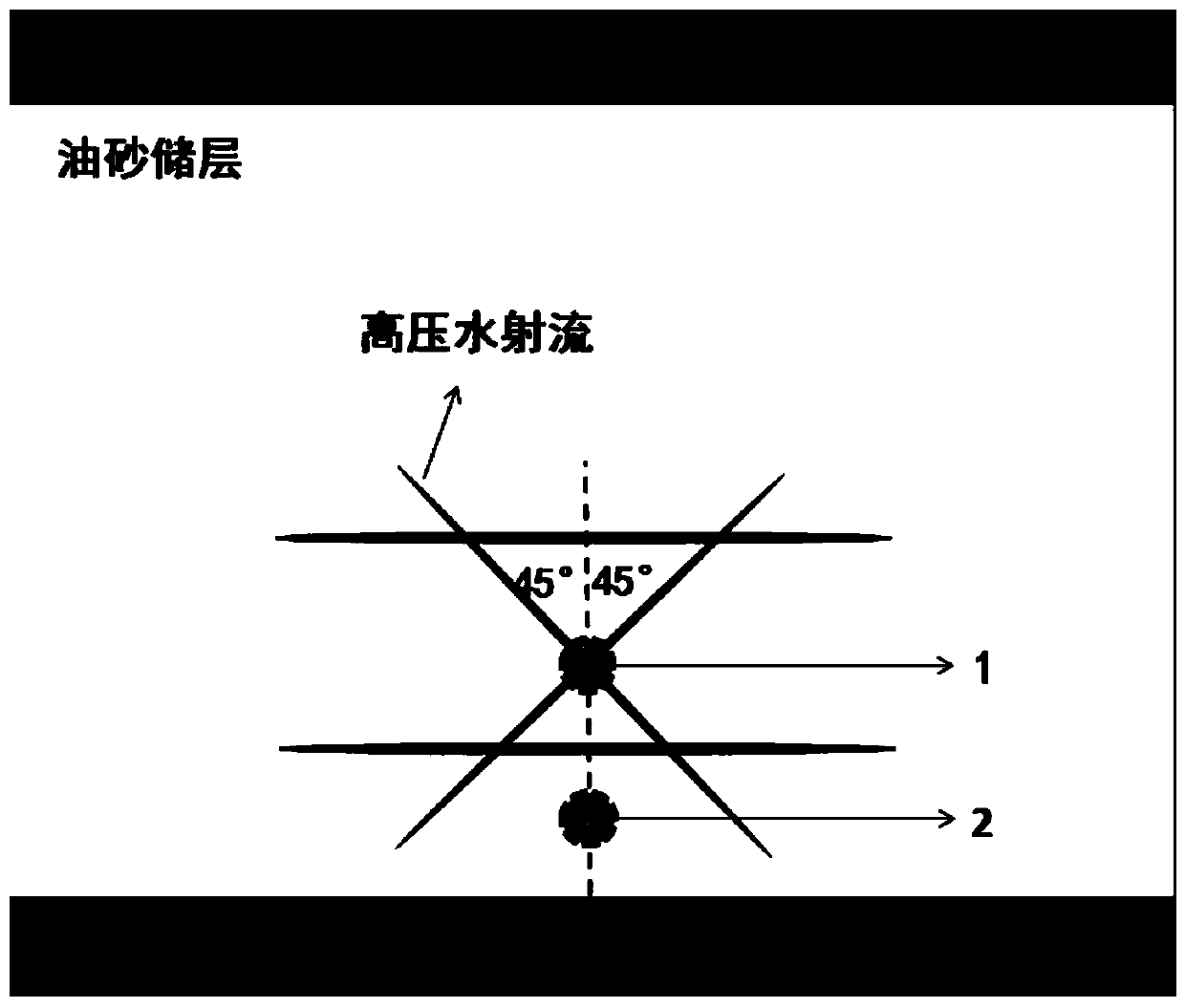

[0043] figure 1 It is a schematic diagram of the fluid squeeze expansion effect of SAGD well without mudstone interlayer reservoir, because there is no obstruction of mudstone interlayer, the expansion area is relatively large; figure 2 It is a schematic diagram of the expansion effect of SAGD wells with mudstone interlayer reservoirs. Due to the barrier effect of mudstone interlayers, the expansion area is affected, which in turn affects the oil production. This embodiment proposes a new concept of hydraulic pulse expansion, which realizes pressurization and expansion of oil sand reservoirs through hydraulic pulse generators, and realizes vibration and crushing of dissolved interlayers, fundamentally solving the hindrance effect of mudstone interlayers.

[0044] The SAGD reservoir of this embodiment is located in Fengcheng Oilfield, Xinjiang. The reservoir is an oil sand reservoir, and there are multiple mudstone interlayers at different depths in the reservoir.

[0045] Su...

Embodiment 2

[0064] According to another embodiment of the SAGD mudstone interlayer's jet-squeezing acid transformation method, its steps, principles, beneficial effects, etc. are the same as those in Embodiment 1, except that:

[0065] The reservoir in this embodiment is located in the Guantao Formation Oilfield, Block Du 84, Shuyi District, Liaohe Oilfield, and the interlayer is a physical interlayer in the sand layer.

[0066] In Step 1, the lateral extension of the mudstone interlayer is 4m. In step 3, the jet pressure used is 30MPa, and the pressure difference is 25MPa; the abrasive with a concentration of 8% is added to the jet liquid; the flow rate of the jet liquid is 2.5m 3 / min, and the jetting time is 15 minutes; the diameter of the wellbore opened by the hydraulic jet is 200 times the diameter of the screen hole on the screen. In Step 5, the foaming agent is cetyltrimethylammonium bromide, and the diverting agent is benzoic acid; the flow rate of the foam acidification reformi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com