Method for testing corrosivity of solid chemical product on metal

A test method and chemical technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, scientific instruments, etc., can solve the problems of inaccurate test results, etc., and achieve the effect of convenient testing, good technical effect, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

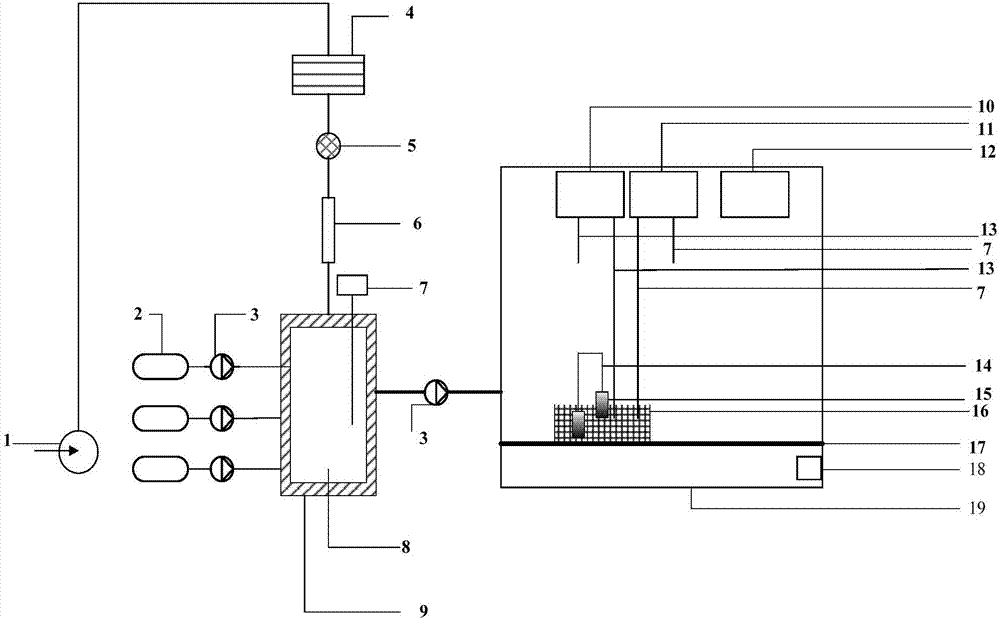

[0029] A test method for the corrosivity of solid chemicals to metals, such as figure 1 As shown, the test device for the corrosivity of solid chemicals to metals is used to test the corrosivity of solid chemicals to metals. The test device for the corrosivity of solid chemicals to metals includes air inlets, other gas intake systems, filters, Regulating valve, flow valve, flow meter, gas mixing chamber with heated outer layer, humidity control system, temperature control system, humidity probe, pressure control system, thermocouple, bracket, plastic mesh cage, support plate, box; The samples to be tested are filled in a plastic square cage and placed in a corrosion test chamber. One of the polished metal test pieces is buried in the sample to be tested, and the other is half buried in the sample to be tested. Set the test temperature, humidity and pressure and Test time: open the intake system, air or the mixture of air and other gases enters the gas mixing chamber with a hea...

Embodiment 2

[0060] Adopt solid chemical of the present invention for the test method and device test of metal corrosion solid polyaluminum chloride at normal temperature, normal pressure, air atmosphere, humidity is under 40%RH, within 168 hours for aluminum sheet (non-composite type 7075-T6) corrosivity. The specific implementation process is as follows:

[0061] (1) After polishing the 2 pieces of aluminum sheet, weigh and record. Take the solid polyaluminium chloride sample and put it into a plastic square cage, bury one piece of polished aluminum sheet in the sample of the plastic square cage, and one piece of aluminum sheet half-buried in the sample of the plastic square cage, and wrap it with a polytetrafluoroethylene wire. The aluminum sheet is fixed on the bracket of the plastic square cage to prevent sinking during the test.

[0062] (2) Place the square cage containing the samples and metal test pieces in the corrosion test chamber, and insert the thermocouple and humidity pro...

Embodiment 3

[0071] Adopt solid chemical of the present invention for the test method and device test of metal corrosion phthalic anhydride at 50 ℃, 2 atmospheres, nitrogen atmosphere, humidity is under 60%RH, within 168 hours for steel sheet (SAE1020 ) corrosiveness. The specific implementation process is as follows:

[0072] (1) Weigh and record the 2 pieces of steel sheet after grinding. Take a sample of phthalic anhydride and put it into a plastic square cage, bury one piece of polished steel sheet in the sample of the plastic square cage, and one half-buried in the sample of the plastic square cage, and wrap it with a polytetrafluoroethylene wire. The steel sheet is fixed on the bracket of the plastic square cage to prevent sinking during the test.

[0073] (2) Place the square cage containing the samples and metal test pieces in the corrosion test chamber, and insert the thermocouple and humidity probe into the square cage.

[0074] (3) Turn on the power of the corrosion test cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com