High-temperature resistant cable

A high-temperature-resistant cable technology, applied in the field of high-temperature-resistant cables, can solve the problems of not meeting the non-toxic requirements and endangering peripheral equipment, etc., and achieve the effects of simple structure, environmental resistance, salt spray resistance, and excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

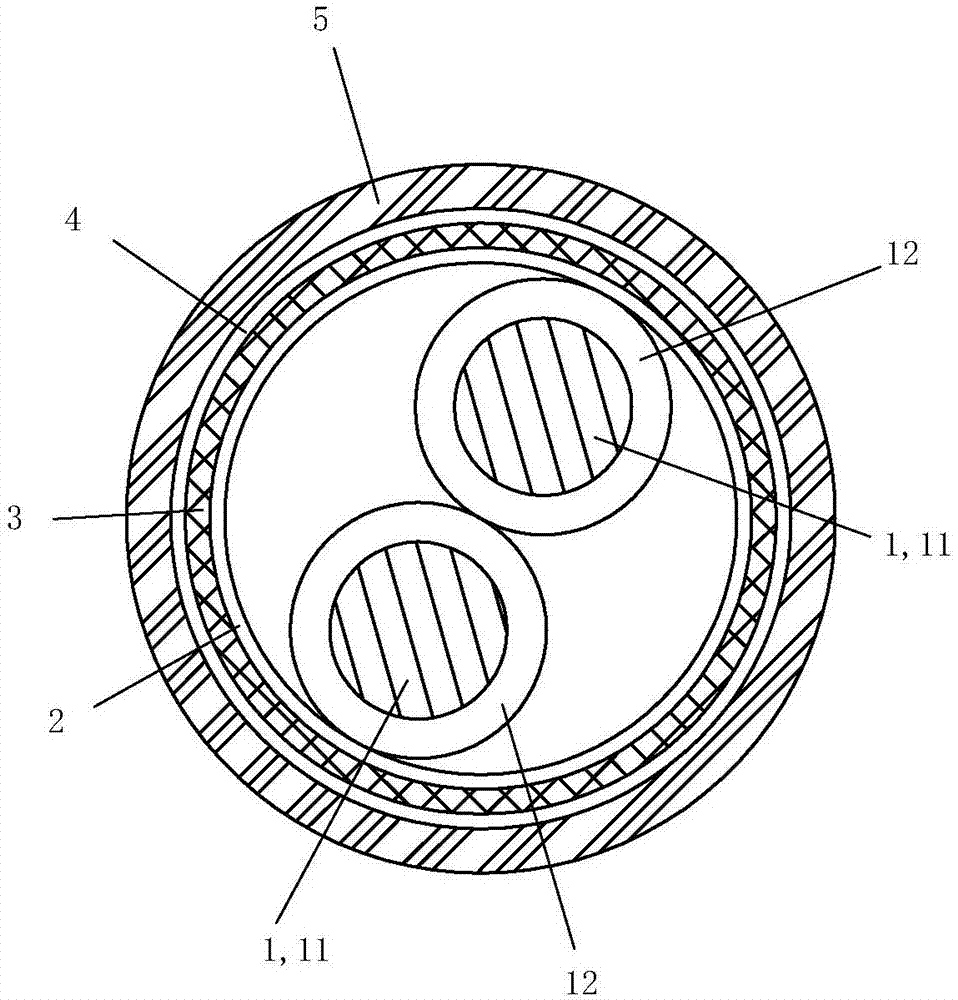

[0020] See figure 1 , The high temperature resistant cable of this embodiment includes a main core 1 , a wrapping layer 2 , a shielding layer 3 , a second wrapping layer 4 and a sheath 5 .

[0021] See figure 1 , There are two main cores 1, the two main cores 1 have the same structure, and the two main cores 1 are provided with conductors 11 and insulating layers 12 in turn along their respective radial directions from inside to outside. The two main cores 1 are twisted into cables.

[0022] See figure 1 , the conductor 11 is made of a number of metal-plated copper wires with the same monofilament diameter twisted in the same direction, and the adjacent layers are twisted in reverse. This embodiment uses 19 tinned copper wires with a nominal diameter of 0.16 mm in the same direction. Twisted, adjacent layers twisted in reverse, the outermost layer is left.

[0023] See figure 1 , The insulating layer 12 is made of polyether ether ketone. The insulating layer 12 is extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com