Battery and fabrication method, charging method and application thereof

A battery and electrolyte technology, which is applied in the manufacture of secondary batteries, secondary batteries, circuits, etc., can solve the problems such as the need to improve the charging efficiency, the difficulty in realizing the battery capacity, the charging time and the charging method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0116] Preparation Example: Preparation of Solid Electrolyte - Polyvinyl Alcohol-Potassium Chloride Composition

[0117] Dissolve 10 g of polyvinyl alcohol in 10 mL of aqueous solution, heat at 85° C., and stir for 2 h to obtain an aqueous solution of polyvinyl alcohol.

[0118] Dissolve 8.5g of potassium chloride in 8.5mL of aqueous solution, heat at 80°C, and stir for 2h to obtain an aqueous solution of potassium chloride.

[0119] The potassium chloride aqueous solution is added to the polyvinyl alcohol aqueous solution to form a mixed solution of polyvinyl alcohol-potassium chloride composition.

[0120] The mixed solution of the polyvinyl alcohol-potassium chloride composition was dried under vacuum at 50° C. for 2 hours to obtain a polyvinyl alcohol-potassium chloride composition, that is, a solid electrolyte.

Embodiment 1

[0122] This embodiment provides a battery that can indicate battery power and energy storage status according to color change, and its preparation method is as follows:

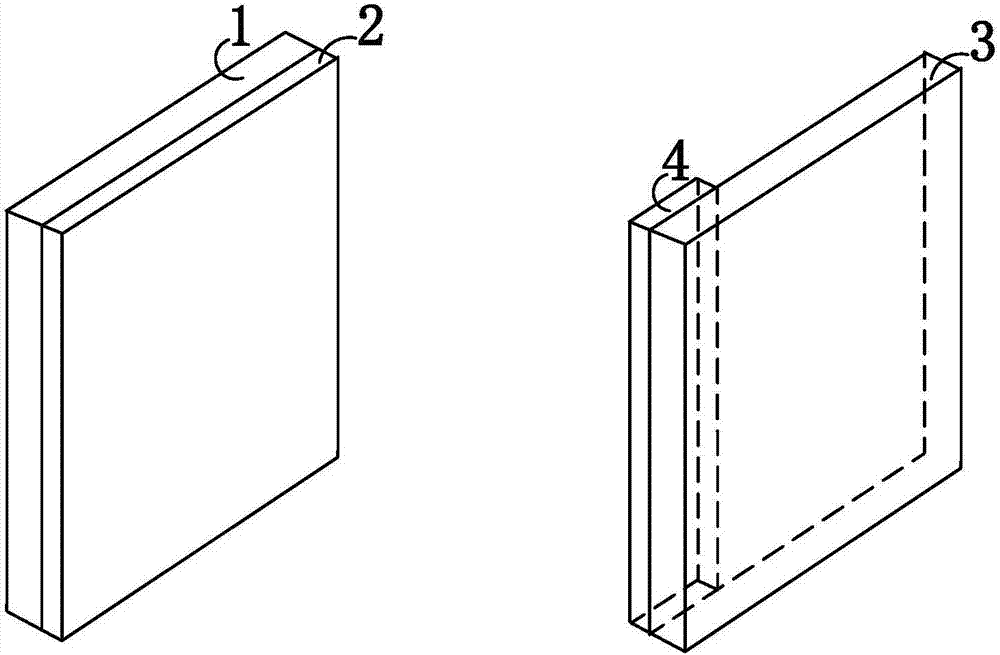

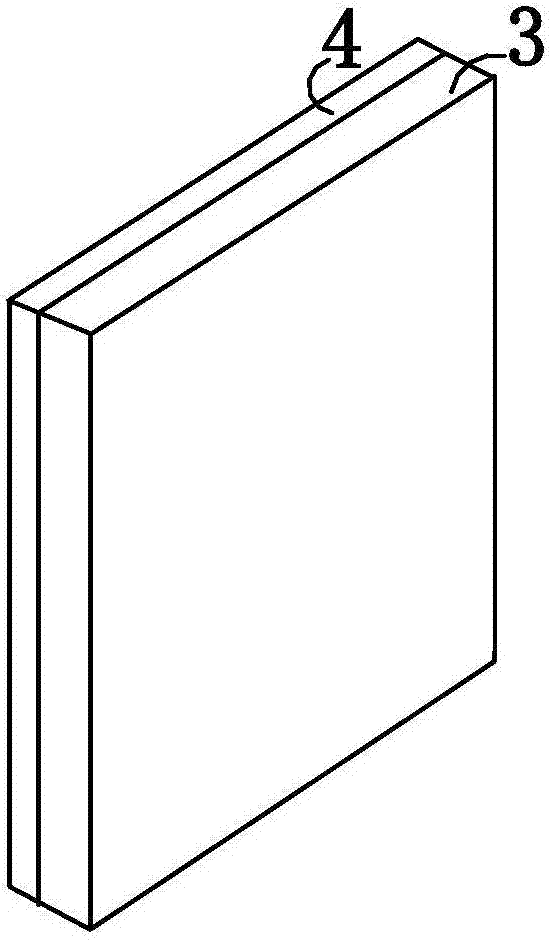

[0123] S1. As shown in Figure 1 (a), provide FTO film (fluorine-doped tin oxide) as the first substrate 1, adopt solvothermal method to grow W on the first substrate 1 18 o 49 As the first active material layer 2 , it is annealed by Ar atmosphere; a second substrate 3 of FTO film is provided, and a metal aluminum foil is set on the second substrate 3 as the second active material layer 4 . It can be understood that, in this embodiment, the metal aluminum foil only partially covers the second substrate, but when other electrochromic materials and conductive composite materials are used as the second active material layer, as shown in Figure 1(b), it can also be The second active material layer 4 is completely covered on the second substrate 3 .

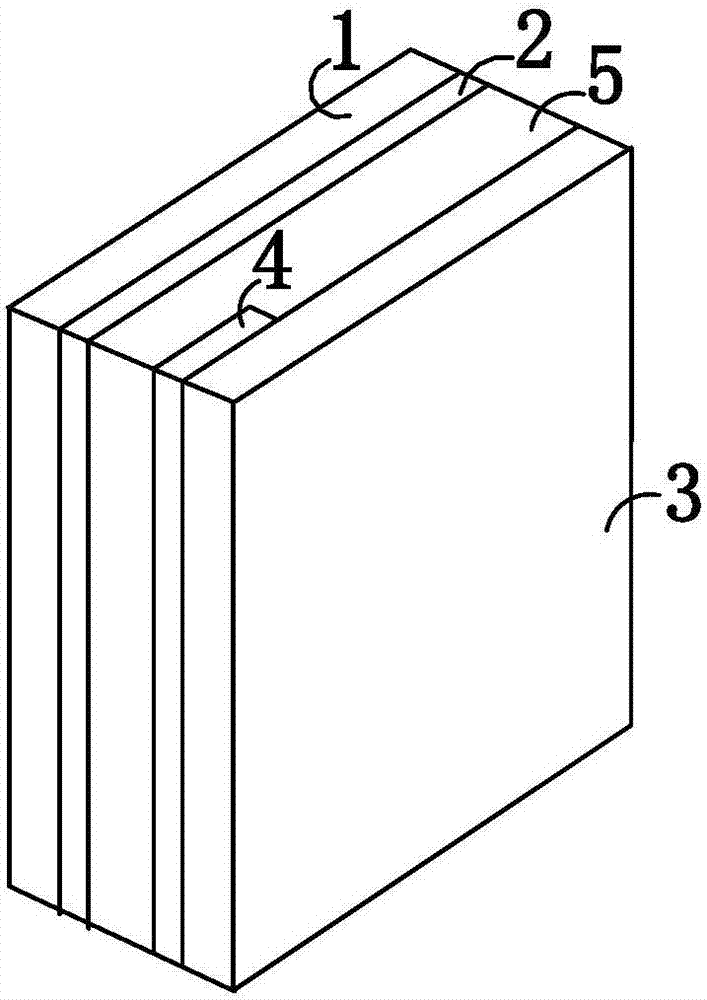

[0124] S2. If figure 2 As shown, the electrolyte 5 is applied...

Embodiment 2

[0130] The difference between this embodiment and embodiment 1 is that in the battery manufacturing method, step S3 only partially seals the edge of the battery.

[0131] The battery in this embodiment can also realize self-charging. Specifically, since only the edge of the battery is partially sealed in this embodiment, the battery can be charged by the contact between air and the battery. Use air to charge the battery three times, the capacity of the battery is about: 100mAh / g, specifically as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com