Etching and cleaning integrated equipment for flexible circuit boards

A flexible circuit board and etching technology, applied in printed circuit, printed circuit manufacturing, printed circuit drying, etc., can solve problems such as inability to clean and dry in time, and achieve good etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

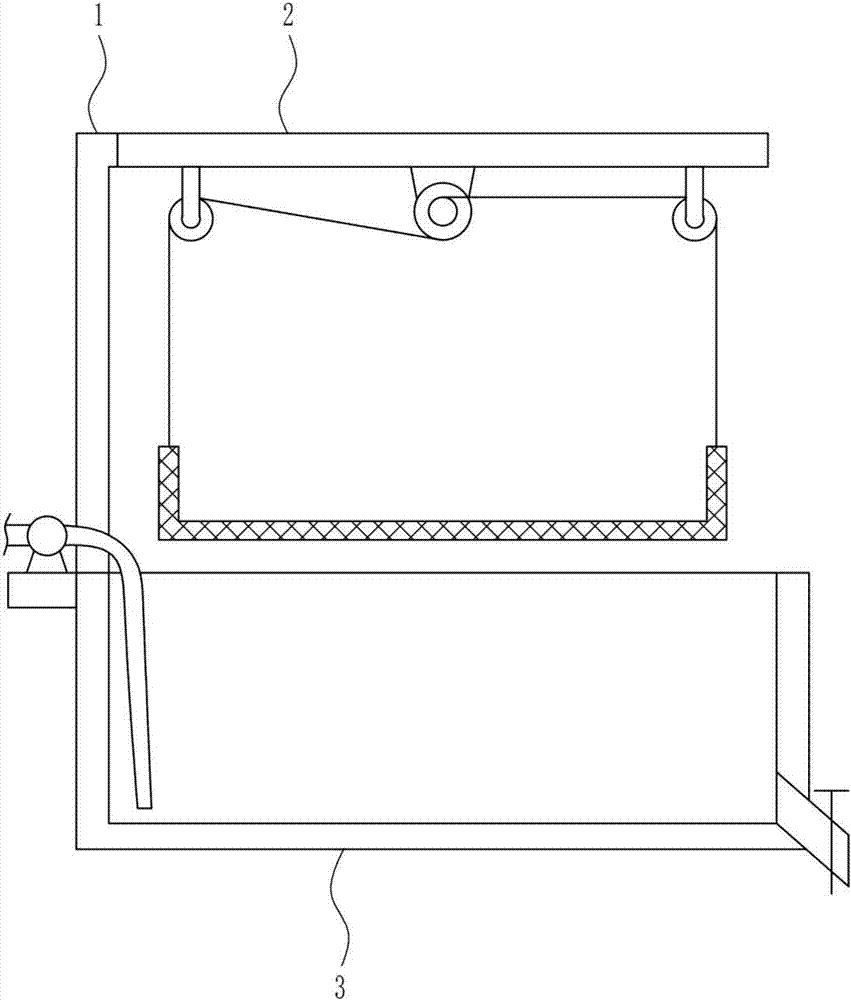

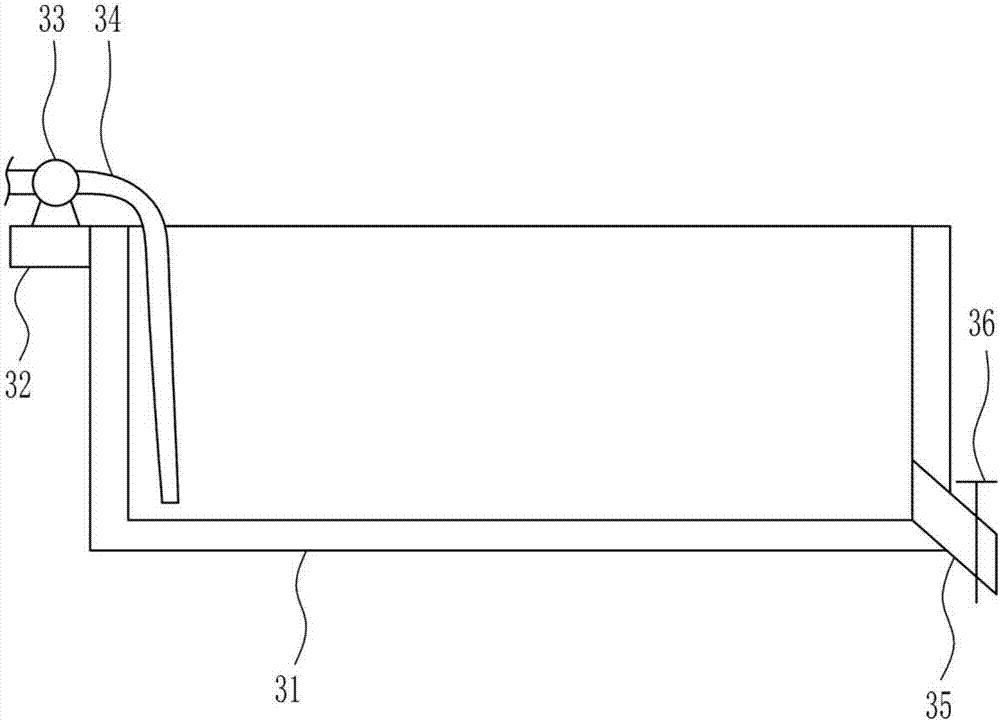

[0037] An integrated equipment for etching and cleaning flexible circuit boards, such as Figure 1-7 As shown, it includes a mounting frame 1 , a lifting mechanism 2 and a reaction mechanism 3 , the bottom of the mounting frame 1 is connected with the reaction mechanism 3 , and the right end of the mounting frame 1 is connected with the lifting mechanism 2 .

Embodiment 2

[0039] An integrated equipment for etching and cleaning flexible circuit boards, such as Figure 1-7 As shown, it includes a mounting frame 1 , a lifting mechanism 2 and a reaction mechanism 3 , the bottom of the mounting frame 1 is connected with the reaction mechanism 3 , and the right end of the mounting frame 1 is connected with the lifting mechanism 2 .

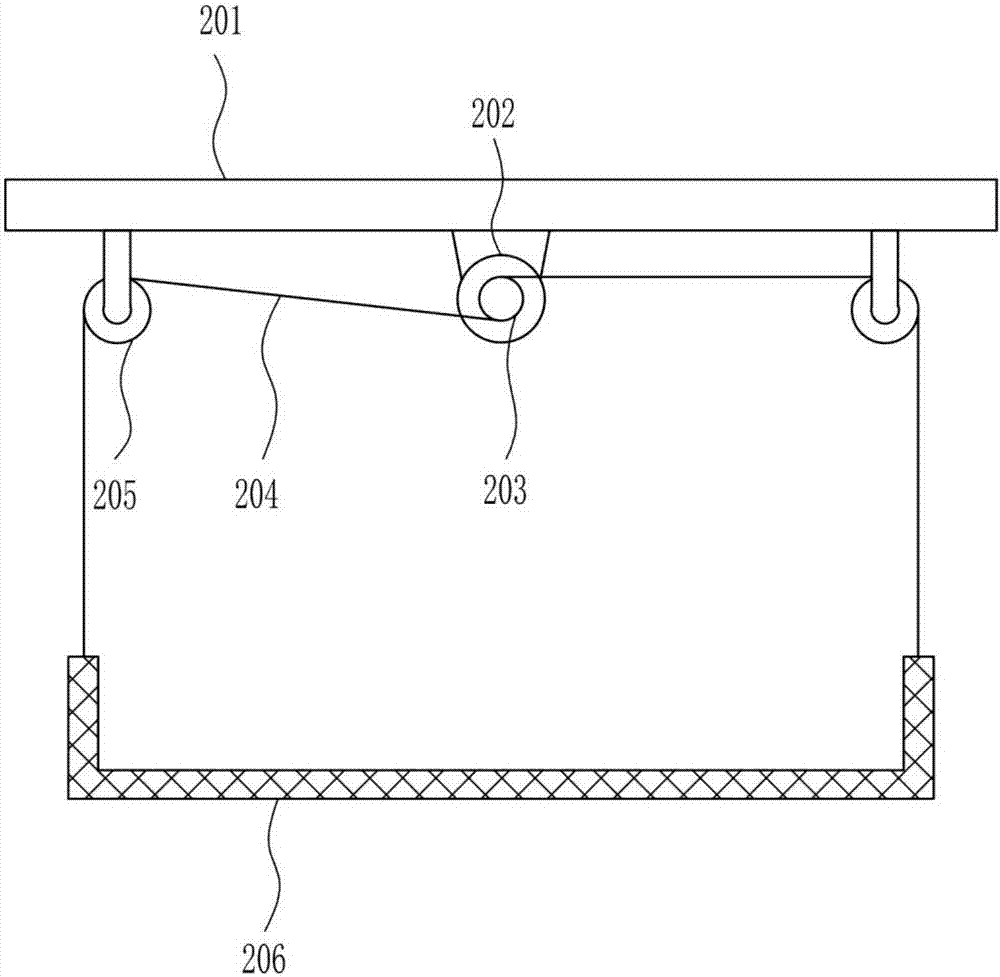

[0040] Elevating mechanism 2 comprises top plate 201, motor 202, reel 203, steel wire rope 204, fixed pulley 205 and filter screen frame 206, and the top right end of installation frame 1 is connected with top plate 201, and the bottom middle of top plate 201 is connected with motor 202, and the motor The front end of the output shaft of 202 is connected with a winding wheel 203, and a steel wire rope 204 is wound on the winding wheel 203. The left and right sides of the bottom of the top plate 201 are symmetrically connected with a fixed pulley 205, and the left and right sides of the steel rope 204 all go around the fix...

Embodiment 3

[0042] An integrated equipment for etching and cleaning flexible circuit boards, such as Figure 1-7 As shown, it includes a mounting frame 1 , a lifting mechanism 2 and a reaction mechanism 3 , the bottom of the mounting frame 1 is connected with the reaction mechanism 3 , and the right end of the mounting frame 1 is connected with the lifting mechanism 2 .

[0043] Elevating mechanism 2 comprises top plate 201, motor 202, reel 203, steel wire rope 204, fixed pulley 205 and filter screen frame 206, and the top right end of installation frame 1 is connected with top plate 201, and the bottom middle of top plate 201 is connected with motor 202, and the motor The front end of the output shaft of 202 is connected with a winding wheel 203, and a steel wire rope 204 is wound on the winding wheel 203. The left and right sides of the bottom of the top plate 201 are symmetrically connected with a fixed pulley 205, and the left and right sides of the steel rope 204 all go around the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com