Drawing protein and preparation method thereof

A technology of drawing protein and plant protein, which is applied in plant protein processing, protein food ingredients, protein food processing, etc., and can solve problems such as poor taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

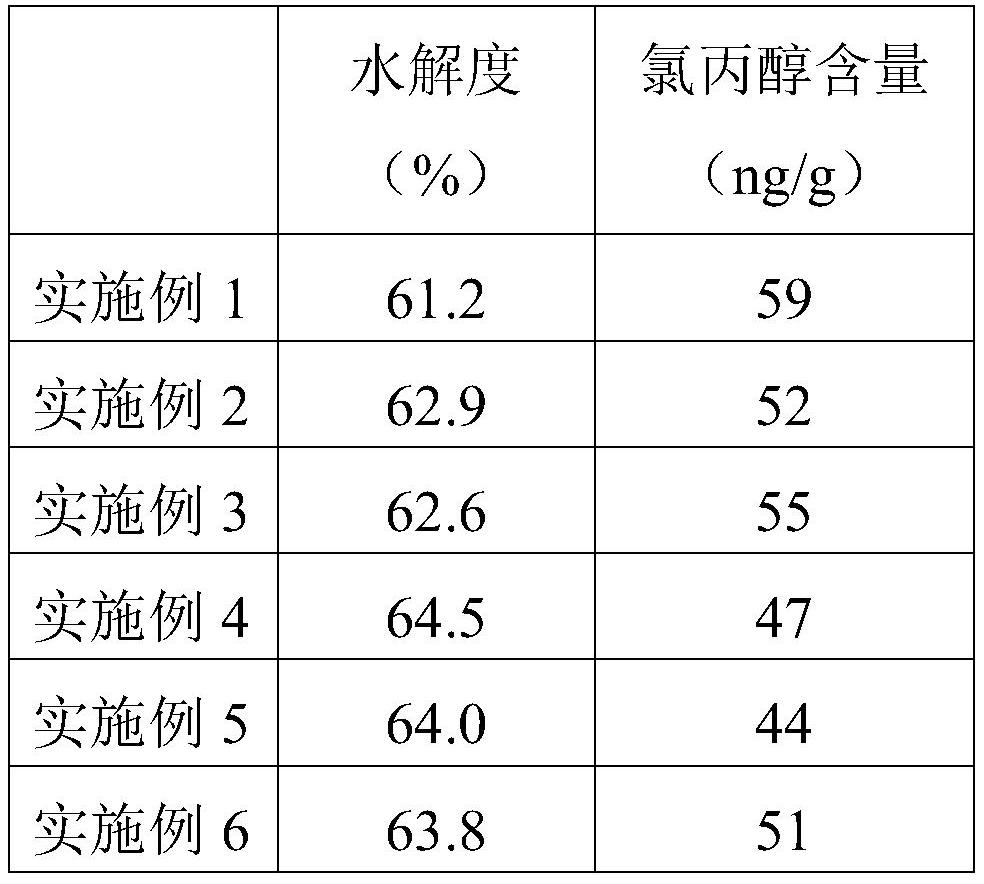

Examples

Embodiment 1

[0043] The preparation method of drawing protein, comprises the following steps:

[0044] (1) 10kg of gluten powder, 20kg of edible soybean meal, 10kg of soybean protein isolate, 2kg of acid hydrolyzed rice protein, 2kg of maltodextrin, and 6kg of drinking water were mixed uniformly for 10 minutes at a speed of 300 rpm to obtain a mixture;

[0045] (2) Extrude and expand the mixture with a twin-screw extruder (Jinan Degu Machinery Equipment Co., Ltd., model DGD70-1), the temperature in the high temperature zone is 180°C, and the temperature in the low temperature zone is 120°C to obtain puffed products;

[0046] (3) cut the puffed product into sections according to the length of 6.5cm;

[0047] (4) Dry the puffed product after cutting in continuous microwave wire-drawing protein drying equipment (Zhuzhou Weilang Technology Co., Ltd., model WLKJ-A70) with a microwave power of 50KW and a transport speed of 3 m / min. Obtain dried embryo material;

[0048] (5) Heat 70kg of drinking...

Embodiment 2

[0052] The preparation method of drawing protein, comprises the following steps:

[0053] (1) 10kg of gluten powder, 20kg of edible soybean meal, 10kg of soybean protein isolate, 2kg of acid hydrolyzed rice protein, 2kg of maltodextrin, and 6kg of drinking water were mixed uniformly for 10 minutes at a speed of 300 rpm to obtain a mixture;

[0054] (2) Extrude and expand the mixture with a twin-screw extruder (Jinan Degu Machinery Equipment Co., Ltd., model DGD70-1), the temperature in the high temperature zone is 180°C, and the temperature in the low temperature zone is 120°C to obtain puffed products;

[0055] (3) cut the puffed product into sections according to the length of 6.5cm;

[0056] (4) Dry the puffed product after cutting in continuous microwave wire-drawing protein drying equipment (Zhuzhou Weilang Technology Co., Ltd., model WLKJ-A70) with a microwave power of 50KW and a transport speed of 3 m / min. Obtain dried embryo material;

[0057] (5) Heat 70kg of drinki...

Embodiment 3

[0061] The preparation method of drawing protein, comprises the following steps:

[0062] (1) 10kg of gluten powder, 20kg of edible soybean meal, 10kg of soybean protein isolate, 2kg of acid hydrolyzed rice protein, 2kg of maltodextrin, and 6kg of drinking water were mixed uniformly for 10 minutes at a speed of 300 rpm to obtain a mixture;

[0063] (2) Extrude and expand the mixture with a twin-screw extruder (Jinan Degu Machinery Equipment Co., Ltd., model DGD70-1), the temperature in the high temperature zone is 180°C, and the temperature in the low temperature zone is 120°C to obtain puffed products;

[0064] (3) cut the puffed product into sections according to the length of 6.5cm;

[0065] (4) Dry the puffed product after cutting in continuous microwave wire-drawing protein drying equipment (Zhuzhou Weilang Technology Co., Ltd., model WLKJ-A70) with a microwave power of 50KW and a transport speed of 3 m / min. Obtain dried embryo material;

[0066] (5) Heat 70kg of drinki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com