Tasty Chinese yam beverage formula and preparation technology

A preparation process and refreshing type technology, which is applied in the direction of food ingredients as taste improvers, food homogenization, food science, etc., can solve the problems of easy browning and aging of starch, poor stability of drinks, and short shelf life, so as to speed up grinding Pulping speed, saving labor and production costs, excellent taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment one is made up of following components by weight:

[0055] 4 parts of erythritol, 2 parts of white sugar, 5 parts of yam, 0.3 parts of condensed milk, 0.2 parts of wheat protein, 0.2 parts of cream, 0.6 parts of dextrin, 0.25 parts of microcrystalline cellulose, 0.02 parts of xanthan gum, carrageenan 0.02 part, 0.12 part of sucrose fatty acid ester, 0.05 part of monostearic acid glyceride, 0.1 part of sodium tripolyphosphate, 0.1 part of sodium hexametaphosphate, 0.03 part of sodium carbonate, 0.035 part of sodium isoVC, 0.1 part of flavoring.

[0056] Embodiment 1 preparation process is:

[0057] A: According to the proportion of the formula, a certain amount of yam will be removed from the sick and disabled, and the sediment will be cleaned. For the first time, it will be refined through the colloid mill. The output particle size of the colloid mill will be adjusted to 2-3 mm. 3 times the amount of water, centrifuged through a filter centrifugal separator,...

Embodiment 2

[0065] Embodiment two is made up of following components by weight:

[0066] 5.5 parts of erythritol, 3.5 parts of white sugar, 6 parts of yam, 0.4 parts of condensed milk, 0.35 parts of wheat protein, 0.35 parts of cream, 0.8 parts of dextrin, 0.3 parts of microcrystalline cellulose, 0.03 parts of xanthan gum, carrageenan 0.03 part, 0.13 part of sucrose fatty acid ester, 0.06 part of monostearic acid glyceride, 0.11 part of sodium tripolyphosphate, 0.12 part of sodium hexametaphosphate, 0.04 part of sodium carbonate, 0.038 part of sodium isoVC, 0.1 part of food flavoring, preparation process Same as embodiment one.

Embodiment 3

[0067] Embodiment three is made up of following components by weight:

[0068] 7 parts of erythritol, 5 parts of white sugar, 7 parts of yam, 0.5 part of condensed milk, 0.5 part of wheat protein, 0.5 part of cream, 1 part of dextrin, 0.35 part of microcrystalline cellulose, 0.04 part of xanthan gum, carrageenan 0.04 part, 0.15 part of sucrose fatty acid ester, 0.07 part of monostearic acid glyceride, 0.12 part of sodium tripolyphosphate, 0.15 part of sodium hexametaphosphate, 0.05 part of sodium carbonate, 0.04 part of sodium iso-VC, 0.1 part of food flavoring, production process Same as embodiment one.

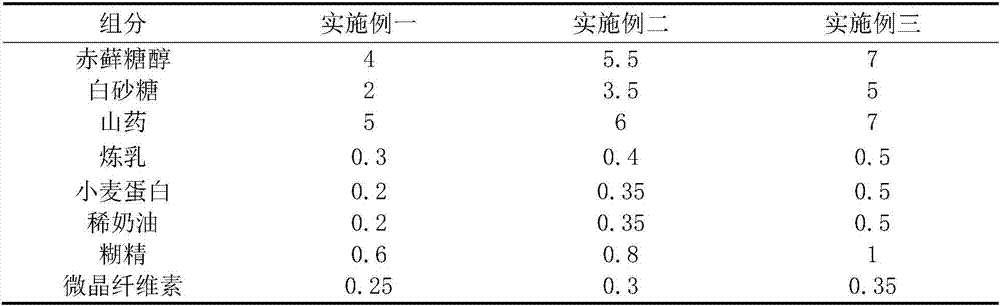

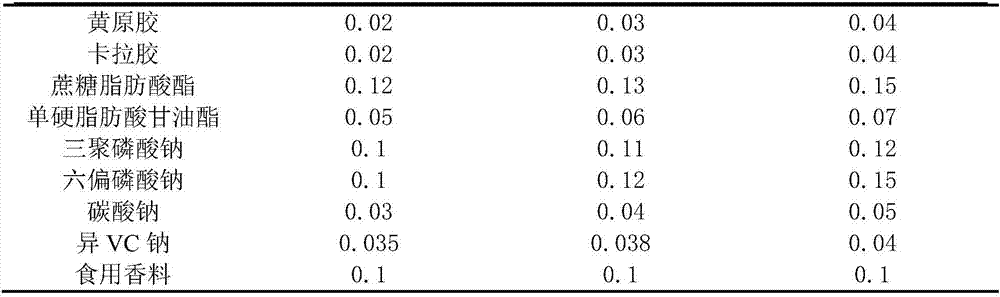

[0069] The formula of embodiment one, embodiment two and embodiment three is as shown in table 1:

[0070] Formulation data of table 1 embodiment one, embodiment two and embodiment three

[0071]

[0072]

[0073] Embodiment 1, Embodiment 2 and Embodiment 3 compared with existing yam beverage, have removed the link of peeling in the beverage production, have saved la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com