Production line for extremely-thin conductors and production process

A production process and conductor production technology, applied in the manufacture of cables/conductors, used to reduce the size of conductors/cables, electrical components, etc., to achieve high yield, low failure rate, and non-deformable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

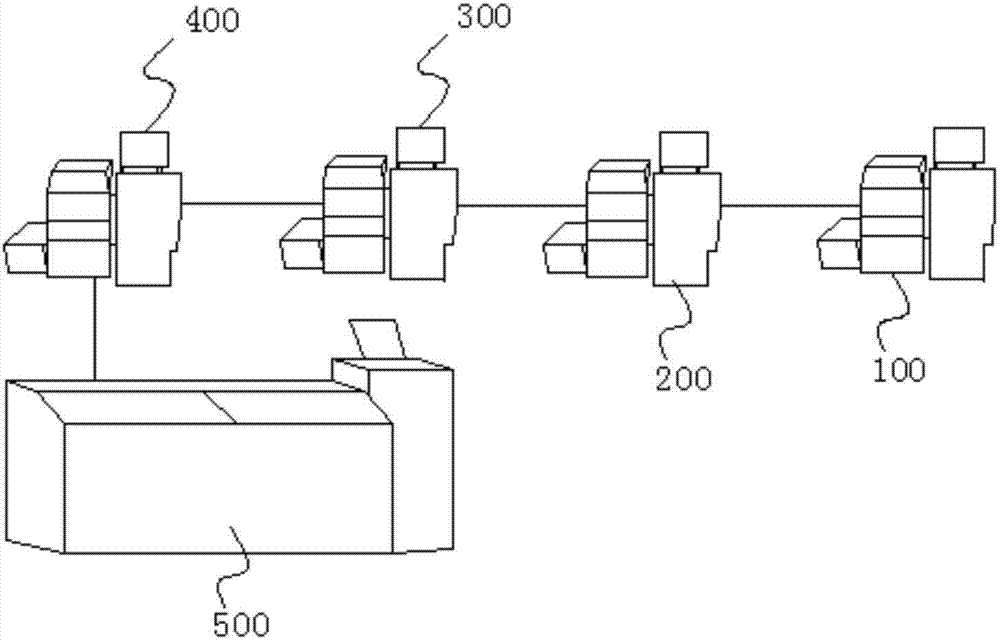

[0035] Embodiment: a kind of ultrafine conductor production line, such as Figure 1 to Figure 3 As shown, it includes a first wire drawing machine 100, a second wire drawing machine 200, a third wire drawing machine 300 and a fourth wire drawing machine 400 arranged in sequence according to the conductor production process;

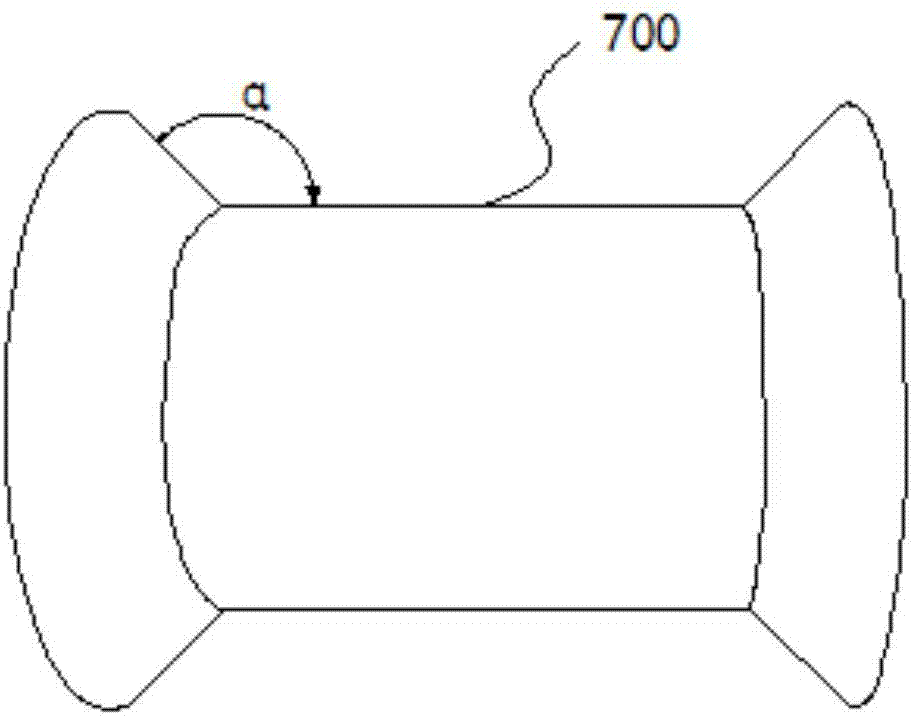

[0036] The first wire drawing machine is sequentially provided with 24 molds according to the conductor processing direction, and the apertures of the eye molds of the molds are successively reduced, wherein the aperture of the eye mold of the first mold is 0.83000-0.85520mm, and the aperture of the eye mold of the 24th mold is The aperture of the eye mold is 0.16000-0.17000mm;

[0037] The second wire drawing machine is sequentially provided with 23 molds according to the conductor processing direction, and the apertures of the eye molds of the molds are successively reduced, wherein the aperture of the eye mold of the first mold is 0.16600-0.15900mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com