Preparation method for polymerized aluminum titanium sulfate and application

A technology of polyaluminum sulfate and aluminum sulfate, which is applied in chemical instruments and methods, wastewater treatment in processing, water/sewage treatment, etc., can solve problems such as ineffective sewage treatment, large dosage of chemicals, threats to human health, etc. Achieve the effect of improving the coagulation effect, strong adsorption and bridging ability, and good coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of polyaluminum titanium sulfate, it is the following steps:

[0025] (1) Weigh a certain quality of aluminum sulfate and add deionized water to fully stir and dissolve to obtain a colorless and transparent solution. Dissolve to obtain a colorless and transparent solution, and control the concentration of the titanium sulfate solution to 0.001-0.01mol / L;

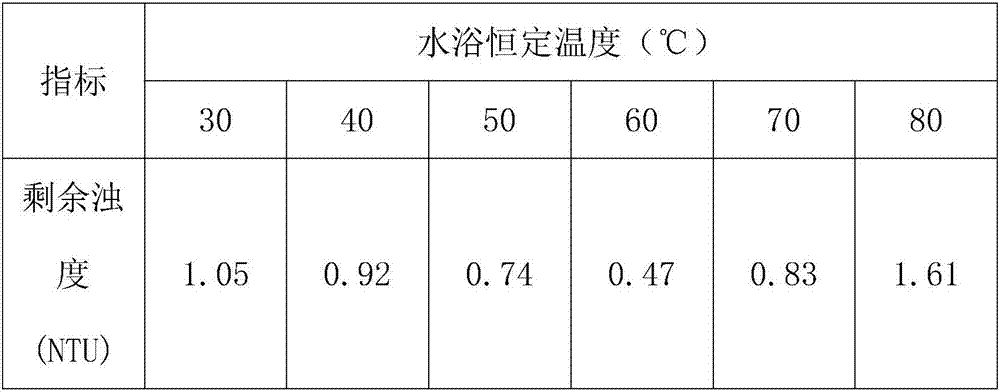

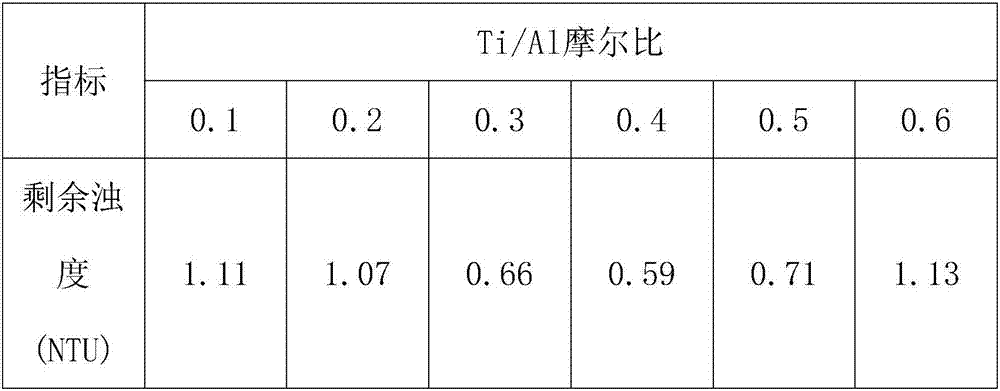

[0026] (2) According to the molar ratio of Ti / Al being 0.1 to 0.6, mix the aluminum sulfate and titanium sulfate solution obtained in step (1), stir in a constant temperature water bath for 1 to 2 hours, and keep the constant temperature at 30-80°C to obtain an aluminum titanium sulfate solution ;

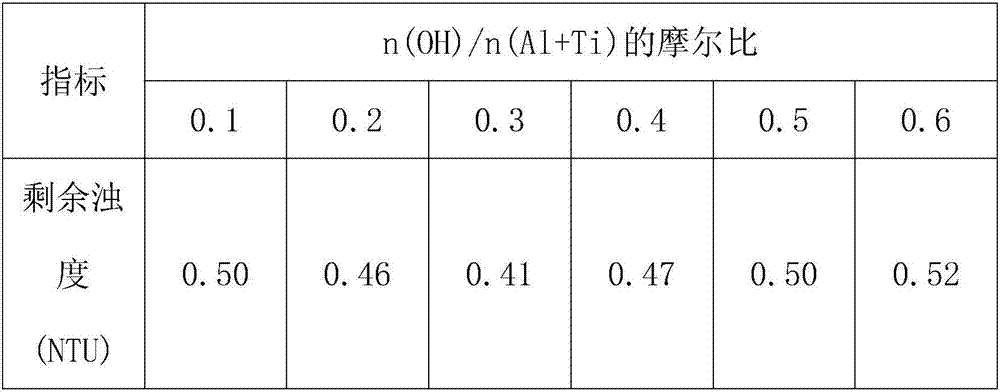

[0027] (3) According to the molar ratio of n(OH) / n(Al+Ti) being 0.1 to 1.0, add sodium hydroxide (NaOH) solution or sodium carbonate (Na 2 CO 3 ) solution, after the dropwise addition, the constant temperature water bath continued to stir for 1 to 2 hours, and the constant temperature was 30...

Embodiment 1

[0034] (1) Weigh 3.3321g of aluminum sulfate (SA) white crystals and dissolve it in about 20mL of deionized water, stir well to dissolve it to obtain a colorless and transparent aluminum sulfate (SA) solution.

[0035] (2) Weigh 0.9600g of titanium sulfate (ST) white crystals and dissolve it in about 20mL of deionized water, stir well to dissolve it to obtain a colorless and transparent titanium sulfate (ST) solution.

[0036] (3) Mix the solutions in (1) and (2) according to the molar ratio of Ti / Al to 0.4, and then place them in a constant temperature water bath at 60°C and stir for 1.0 h to obtain titanium aluminum sulfate with a molar ratio of Ti / Al of 0.4 solution (SAT).

[0037] (4) According to the molar ratio of n(OH) / n(Al+Ti) being 0.3, adding sodium hydroxide (NaOH) or sodium carbonate (NaOH) with a concentration of 1mol / L to the mixed solution in (3) dropwise 2 CO 3 ) solution, after the dropwise addition, the 60°C constant temperature water bath continued to stir...

Embodiment 2

[0040] A kind of preparation method of polyaluminum titanium sulfate, it is the following steps:

[0041] (1) Take a certain quality of aluminum sulfate and add deionized water to fully stir and dissolve to obtain an aluminum sulfate solution with a concentration of 0.03mol / L. Take a certain quality of titanium sulfate and add deionized water to fully stir and dissolve to obtain a concentration of 0.004mol / L Titanium sulfate solution;

[0042] (2) According to the molar ratio of Ti / Al being 0.35, the aluminum sulfate and titanium sulfate solution obtained in step (1) were mixed, stirred in a constant temperature water bath for 1.5 hours, and the constant temperature was 60° C. to obtain an aluminum titanium sulfate solution;

[0043] (3) According to the molar ratio of n(OH) / n(Al+Ti) being 0.4, sodium hydroxide (NaOH) or sodium carbonate (NaOH) or sodium carbonate (Na 2 CO 3 ) solution, after the dropwise addition, the constant temperature water bath continued to stir for 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com