Sewage treatment system

A sewage treatment system and sewage technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

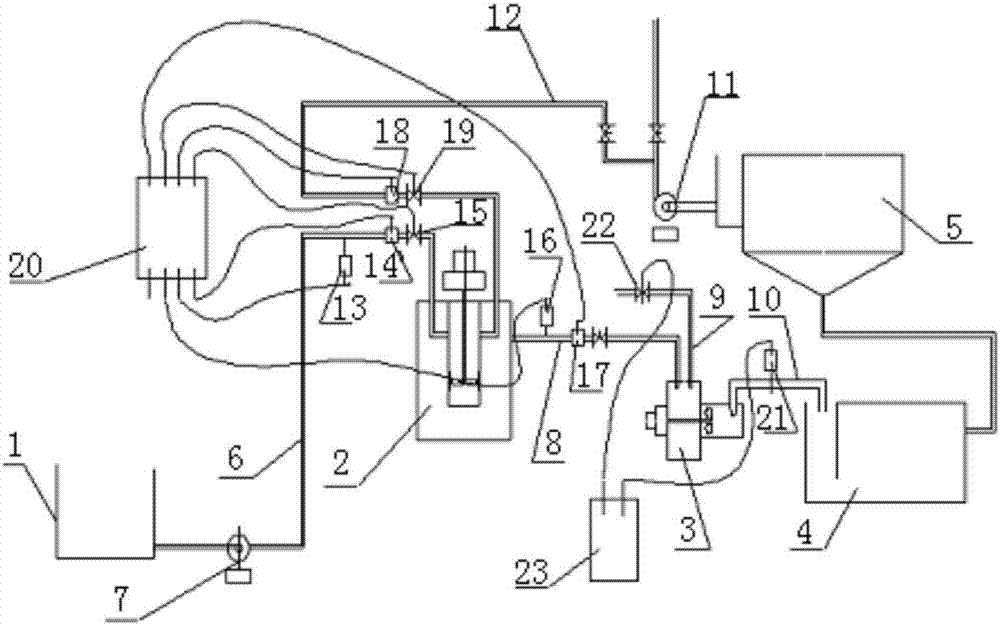

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0025] Such as figure 1 As shown, a sewage treatment system includes a sewage tank 1, an agitator 2, a neutralizer 3, a biochemical tank 4 and a sedimentation tank 5, the sewage tank 1 and the agitator 2 are communicated through a sewage pipe 6, and the sewage pipe 6 is provided with The sewage lifting pump 7, the sewage lifting pump 7 pumps the sewage in the sewage pool 1 into the agitator 2 through the sewage pipe 6; the output end of the agitator 2 communicates with the input end of the neutralizer 3 through the sewage reconciliation pipe 8, neutralizes The input end of the device 3 is also communicated with the lime milk pipe 9 that introduces lime milk; the output end of the neutralizer 3 is communicated with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com