Method for preparing pure inorganic perovskite film under assistance of polyethylene glycol

A technology of polyethylene glycol and inorganic calcium, applied in chemical instruments and methods, luminescent materials, coatings, etc., can solve the problems of uneven distribution of film components, high probability of non-radiative transition, and short exciton radiation lifetime. Good compactness, short heat treatment time, and excellent luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Present embodiment relates to a kind of method that polyethylene glycol, lead bromide and cesium bromide are dissolved in dimethyl sulfoxide DMSO and one step is spin-coated on the perovskite thin film that obtains on glass slide substrate, and described method comprises The following steps:

[0032] Dissolve 0.0630g of lead bromide and 0.0384g of cesium bromide in 0.5ml of DMSO to obtain 15.57wt% pure inorganic CsPbBr 3 Precursor solution A;

[0033] Weigh 0.04g polyethylene glycol (average molecular weight 2w) and dissolve it in 2ml DMSO to obtain 20mg / ml PEG solution B;

[0034] Take 150ul precursor solution A, then pipette 265ul polyethylene glycol solution B, and mix to obtain solution C. At this time, CsPbBr in solution C 3 The concentration is 6.25wt%, the PEG concentration is 1.15wt%, and stirred at room temperature for 4h;

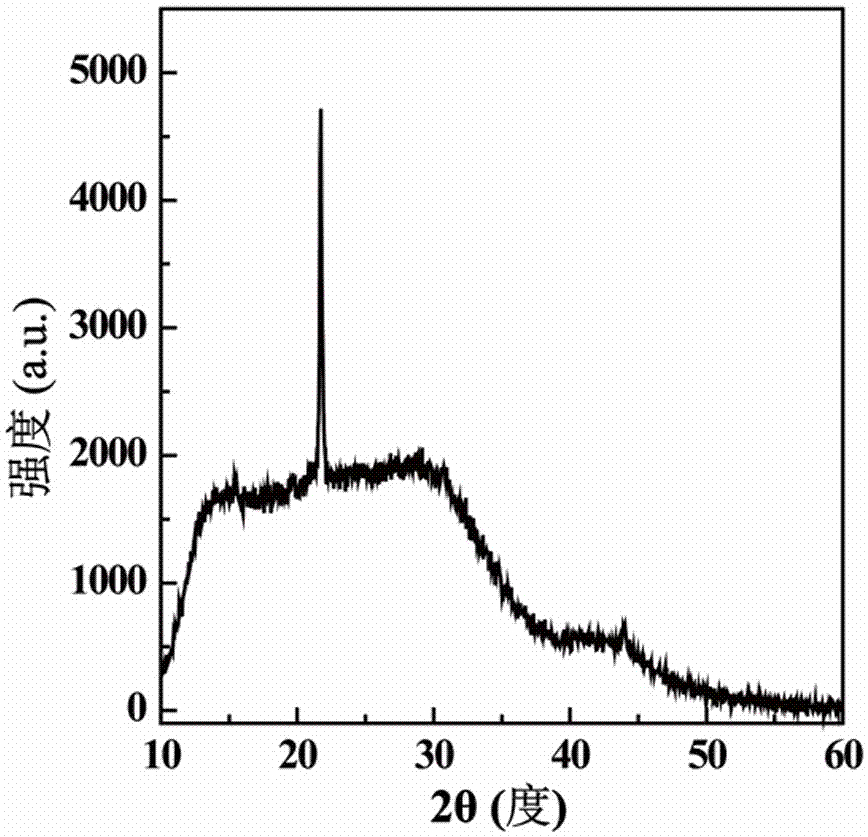

[0035] Spin-coat solution C evenly on a glass slide at 3000rpm for 60s, and dry at 70°C for 5min to obtain a pure inorganic perovskite ...

Embodiment 2

[0040] Present embodiment relates to a kind of method that polyethylene glycol, lead bromide and cesium bromide are dissolved in dimethyl sulfoxide DMSO and one step is spin-coated on the perovskite thin film that obtains on glass slide substrate, and described method comprises The following steps:

[0041] Dissolve 0.0630g of lead bromide and 0.0384g of cesium bromide in 0.5ml of DMSO to obtain pure inorganic CsPbBr 3 Precursor solution A, the solution concentration is 15.57wt%;

[0042] Weigh 0.02g polyethylene glycol (average molecular weight 2w) and dissolve it in 2ml DMSO to obtain 10mg / ml PEG solution B;

[0043] Take 150ul precursor solution A, then pipette 265ul polyethylene glycol solution B, and mix to obtain solution C. At this time, CsPbBr in solution C 3 The concentration is 6.25wt%, the PEG concentration is 0.58wt%, and stirred at room temperature for 4h;

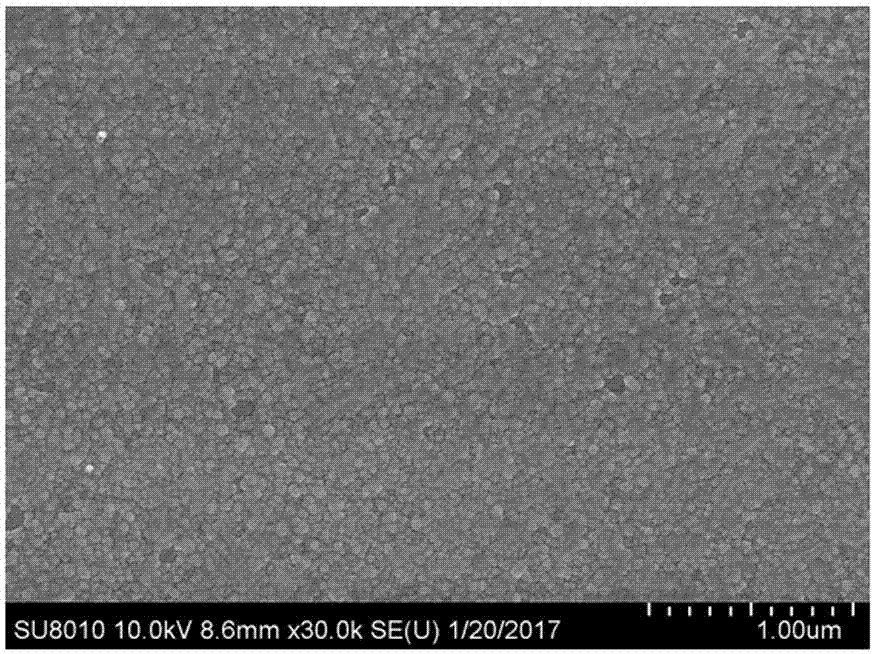

[0044]Spin-coat solution C evenly on a glass slide at 3000rpm for 60s, and dry at 70°C for 5min to obtai...

Embodiment 3

[0047] Present embodiment relates to a kind of method that polyethylene glycol, lead bromide and cesium bromide are dissolved in dimethyl sulfoxide DMSO and one step is spin-coated on the perovskite thin film that obtains on glass slide substrate, and described method comprises The following steps:

[0048] Dissolve 0.0630g of lead bromide and 0.0384g of cesium bromide in 0.5ml of DMSO to obtain pure inorganic CsPbBr 3 Precursor solution A, the solution concentration is 15.57wt%;

[0049] Weigh 0.05g polyethylene glycol (average molecular weight 2w) and dissolve it in 2ml DMSO to obtain 25mg / ml PEG solution B;

[0050] Take 150ul precursor solution A, then pipette 265ul polyethylene glycol solution B, and mix to obtain solution C. At this time, CsPbBr in solution C 3 The concentration is 6.25wt%, the PEG concentration is 1.43wt%, and stirred at room temperature for 4h;

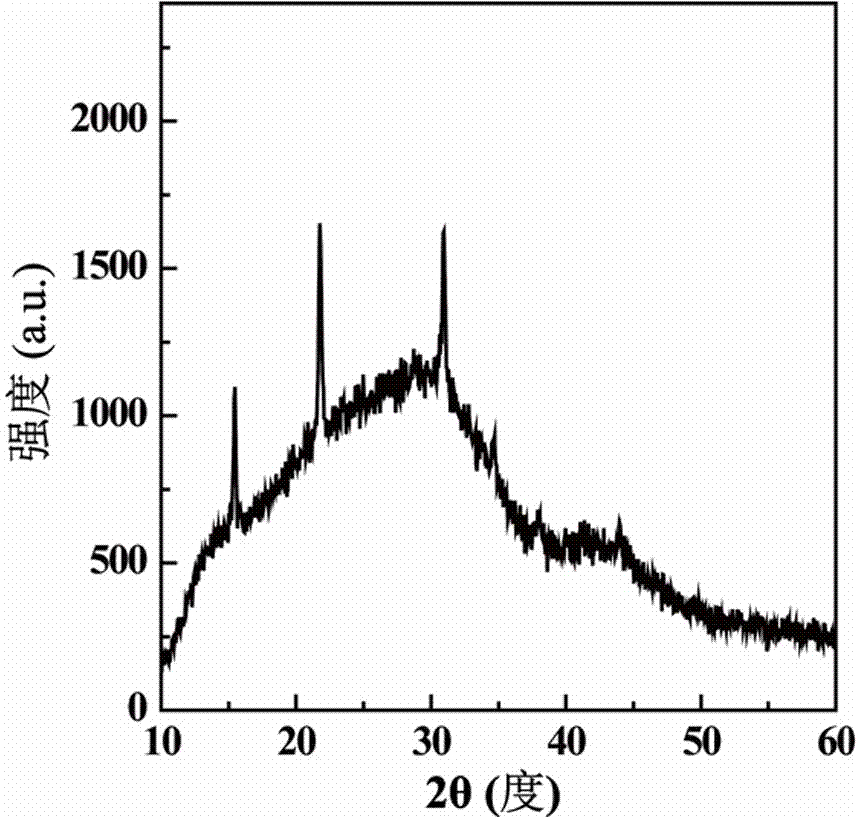

[0051] The obtained solution C was evenly covered on the glass slide by spin coating at 3000rpm for 60s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com