Anti-scratch conductive coating

A conductive coating, anti-scratch technology, applied in conductive coatings, coatings, polyester coatings, etc., can solve the problems of conductive coating cracks, unfavorable conductive properties, insufficient reliability, etc., to reduce the contact area, improve Anti-scratch performance, the effect of reducing scratch damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

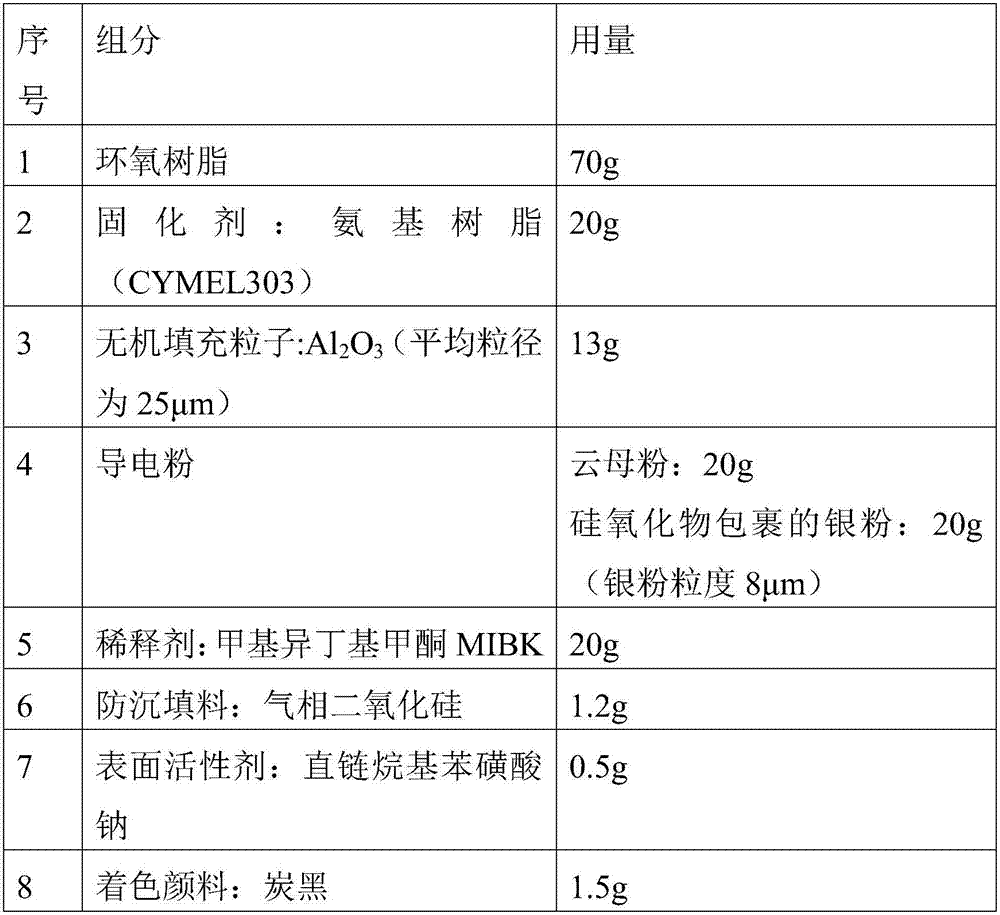

[0025] A formulation of conductive coating is as follows:

[0026]

[0027]

[0028] Preparation of conductive coating:

[0029] (1) Add serial numbers 1, 2, 5, and 9 into the mixing tank and stir evenly;

[0030] (2) Continue stirring, and add serial numbers 3, 4, 6, 7, and 8 and continue stirring to obtain a conductive coating.

[0031] (3) Coating: select the base material, wash and degrease, scrape coat with No. 13 wire rod, bake at 122°C for 12s.

Embodiment 2

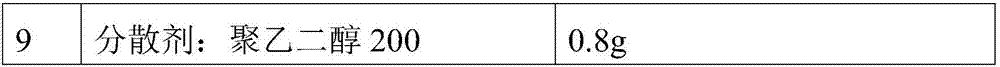

[0033] A formulation of conductive coating is as follows:

[0034]

[0035] Preparation of conductive coating:

[0036] (1) Add serial numbers 1, 2, 5, and 9 into the mixing tank and stir evenly;

[0037] (2) Continue stirring, and add serial numbers 3, 4, 6, 7, and 8 and continue stirring to obtain a conductive coating.

[0038] (3) Coating: select the base material, wash and degrease, scrape coat with No. 13 wire rod, bake at 110°C for 15s.

Embodiment 3

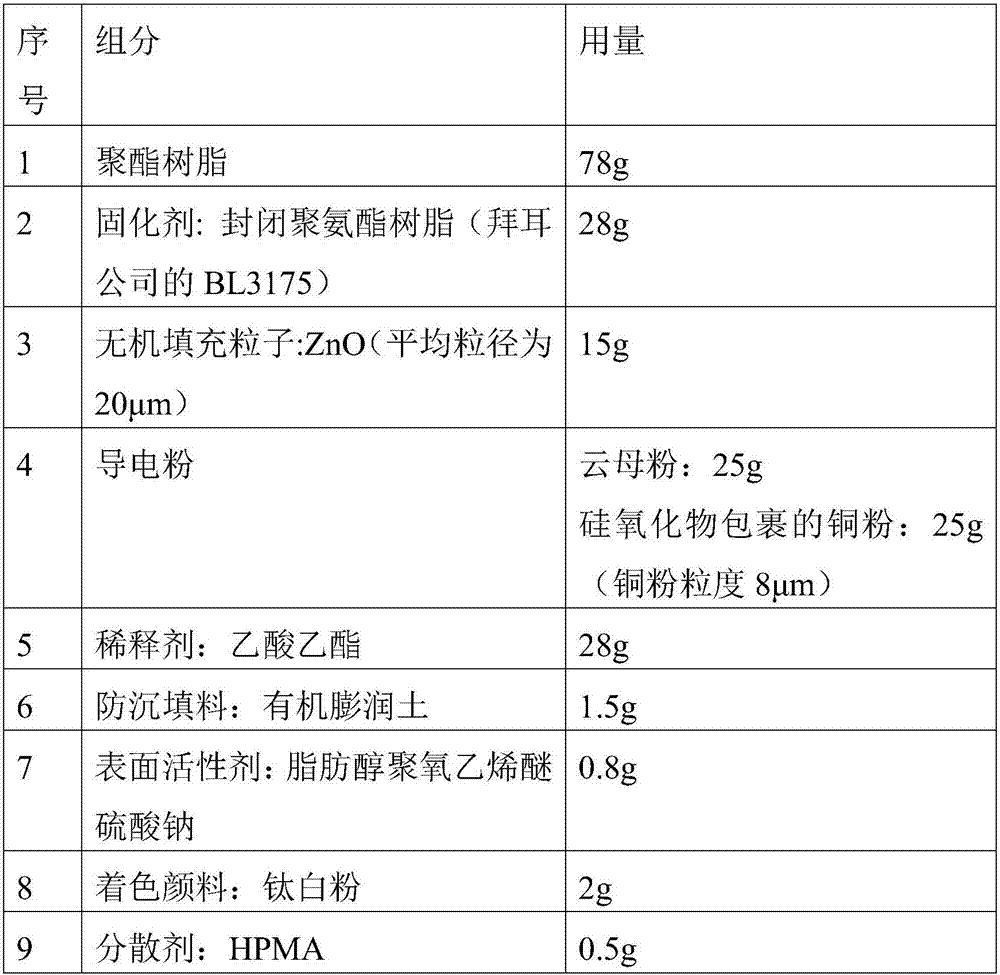

[0040] A formulation of conductive coating is as follows:

[0041]

[0042] Preparation of conductive coating:

[0043] (1) Add serial numbers 1, 2, 5, and 9 into the mixing tank and stir evenly;

[0044] (2) Continue stirring, and add serial numbers 3, 4, 6, 7, and 8 and continue stirring to obtain a conductive coating.

[0045] (3) Coating: select the base material, wash and degrease, scrape coat with No. 13 wire rod, bake at 130°C for 5s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com