Solid food acesulfame potassium pretreatment and rapid detection method

A technology of acesulfame potassium and detection method, applied in the field of chemistry, can solve problems such as no published patent documents and the like, and achieve the effects of convenient pretreatment and detection operations, fast and accurate detection, and fast and convenient pretreatment and detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

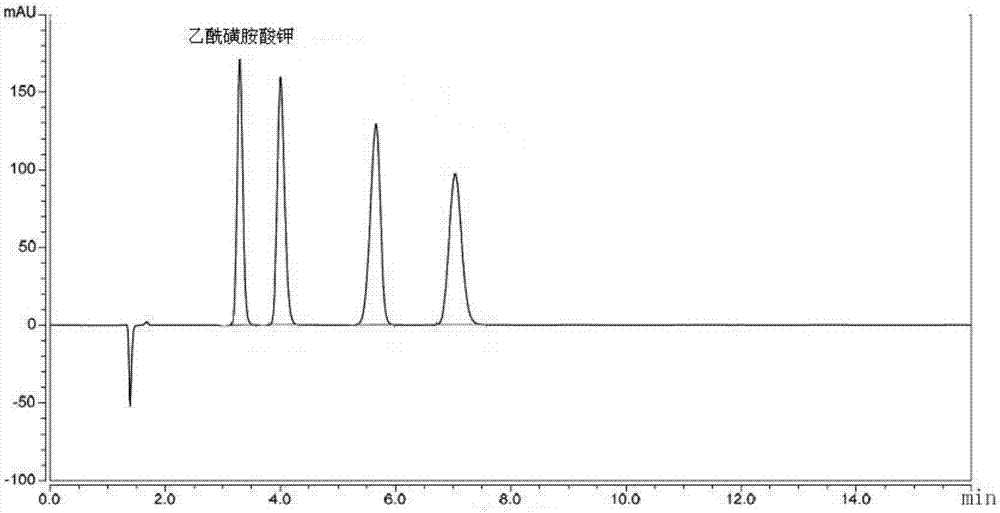

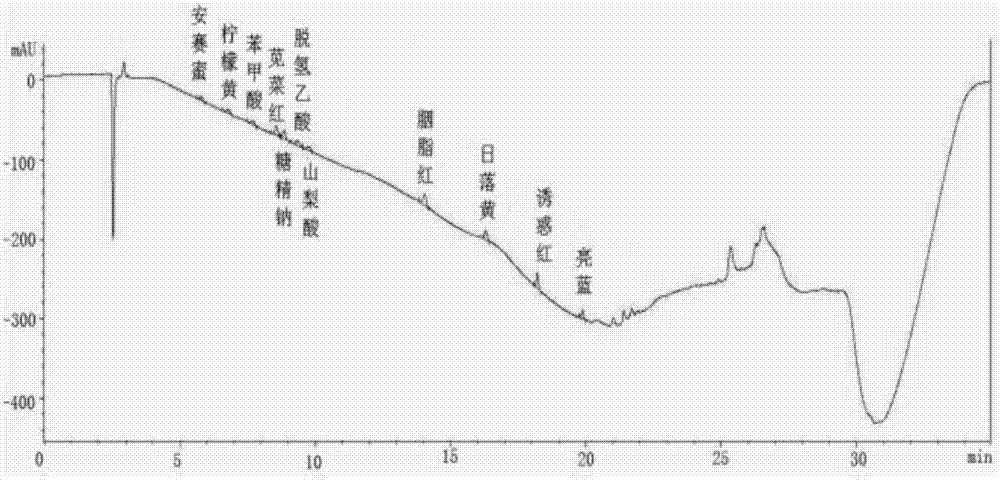

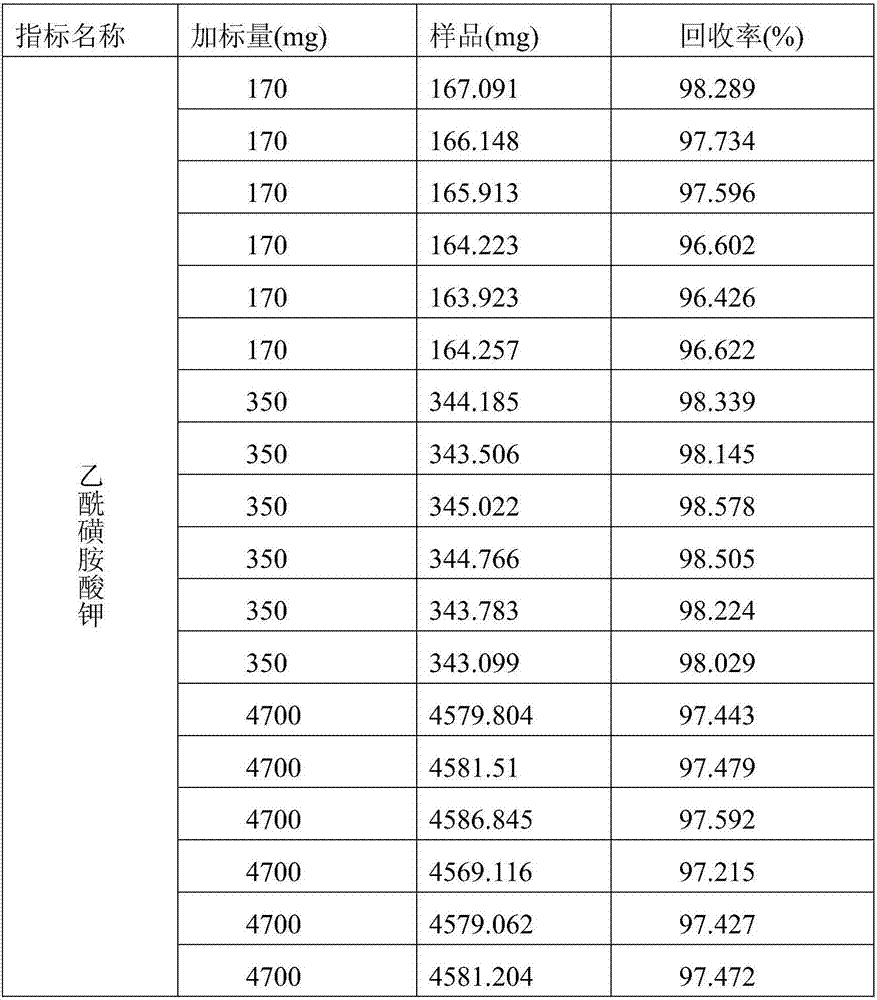

[0042] A method for pretreatment and rapid detection of acesulfame potassium in solid food, characterized in that: the method comprises the following steps:

[0043] 1) Standard solution preparation:

[0044] Accurately weigh the acesulfame potassium standard substance, dissolve and dilute it with ultrapure water, dilute to 1L with a 2:98 methanolic ammonium acetate mixed solution, and prepare acesulfame potassium standard mother solution with a concentration of 0.8g / L. Measure 0.05mL, 0.5mL, 2mL, 5mL, 8mL, 10mL of acesulfame potassium standard mother solution and dilute to 100mL to prepare 0.5mL / L, 5mL / L, 20mL / L, 50mL / L, 80mL / L, 100mL Acesulfame potassium standard solution of / L, standby;

[0045] 2) Sample solution pretreatment and prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com