Longitudinal stiffness control method and bridge of long-span concrete continuous rigid frame bridge with high piers

A technology of longitudinal stiffness and control method, applied in instrumentation, geometric CAD, calculation, etc., can solve the problems that it is difficult to control the longitudinal stiffness of continuous rigid frame bridges with high piers and large spans, and the longitudinal stiffness of bridges is difficult to meet the coupling dynamic characteristics of vehicles and bridges.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Such as Figure 26 As shown, the longitudinal stiffness control method of long-span concrete continuous rigid frame bridge with high piers includes the following steps:

[0077] a. Establish an integrated calculation model of line piers, and simplify the rigid frame piers to the way that fixed supports correspond to independent piers;

[0078] b. Check and calculate the strength and stability of the track under different working conditions;

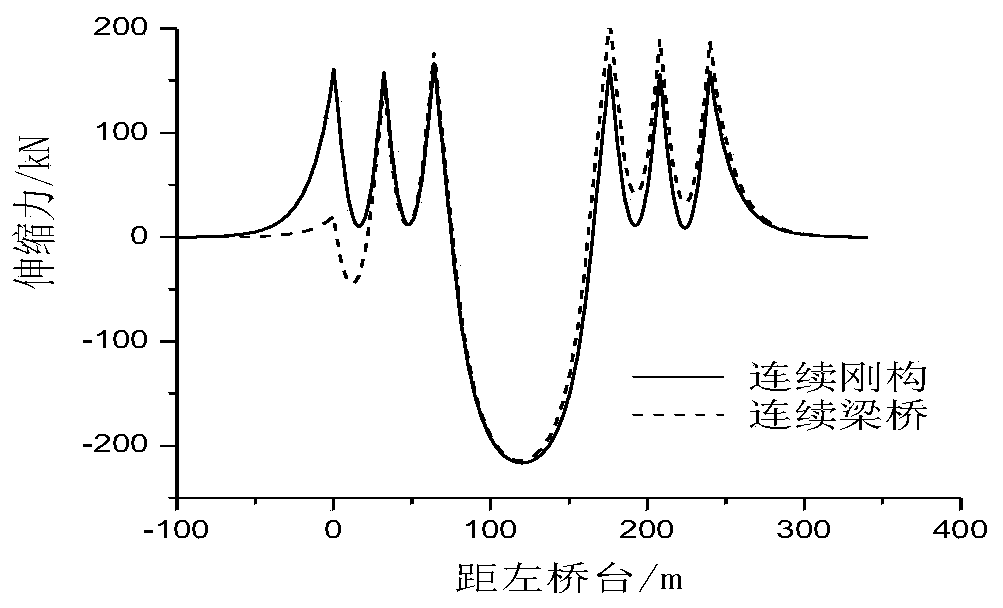

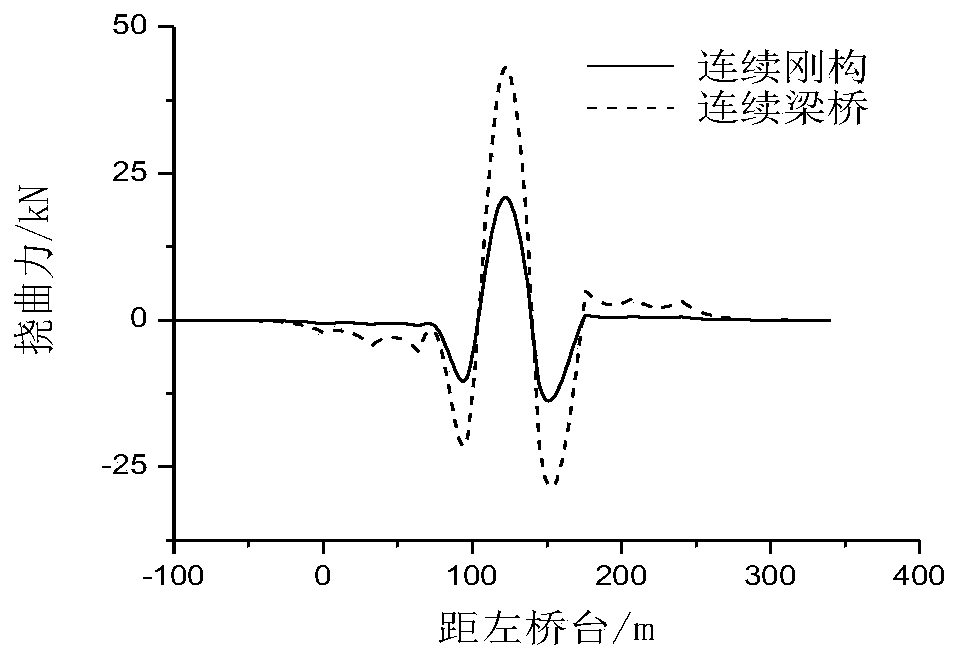

[0079] c. Apply loads, apply different loads to the continuous rigid frame bridge, and check the influence of each load on the force deformation of the seamless line, the loads include wind loads, temperature loads and loads generated by foundation settlement;

[0080] d. Determine the stiffness limit, use the finite element method to analyze the beam-rail interaction force and mutual displacement, and perform numerical solutions to determine the longitudinal stiffness limit of the fixed pier;

[0081] e. Determine the beam layou...

Embodiment 2

[0101]High-pier long-span concrete continuous rigid-frame bridge, the continuous rigid-frame bridge is a ballasted track, the high-pier long-span concrete continuous rigid-frame bridge obtained according to the longitudinal stiffness control method described in Example 1, the continuous rigid-frame bridge is In the case of different nominal temperature spans, the longitudinal stiffness limit of the fixed pier and the track treatment measures meet the following table 1.

[0102] Table 1 The rigidity limit of the longitudinal line of the fixed pier of the ballasted track continuous rigid frame beam

[0103]

[0104]

[0105] The calculation results of the seamless track on ballast track rigid frame bridges under various working conditions are highly correlated with the value of the stiffness of the abutment. Value, so that the pier stiffness selection of rigid frame bridges with different spans is more rational and scientific, on the one hand, it can ensure the safety of t...

Embodiment 3

[0131] High-pier long-span concrete continuous rigid-frame bridge, the continuous rigid-frame bridge is a ballastless track, the high-pier long-span concrete continuous rigid-frame bridge obtained according to the longitudinal stiffness control method described above, the continuous rigid In the case of temperature span, the longitudinal stiffness limit of the fixed pier and the track treatment measures meet the following table 4.

[0132] Table 4 Limits of longitudinal line stiffness of fixed piers of ballastless track continuous rigid frame beams

[0133]

[0134]For ballastless track rigid frame bridges, the calculation results of the seamless track under various working conditions are highly correlated with the value of the abutment stiffness. Value, so that the pier stiffness selection of rigid frame bridges with different spans is more rational and scientific, on the one hand, it can ensure the safety of the line, and on the other hand, it can also save engineering in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com