Harmonic current suppression method, device, equipment and storage medium

A harmonic current and current technology, applied in the field of motors, can solve the problems of poor harmonic suppression effect, complex realization form, and high resource consumption, and achieve the effect of good harmonic suppression effect, saving resource consumption, and reducing the amount of calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

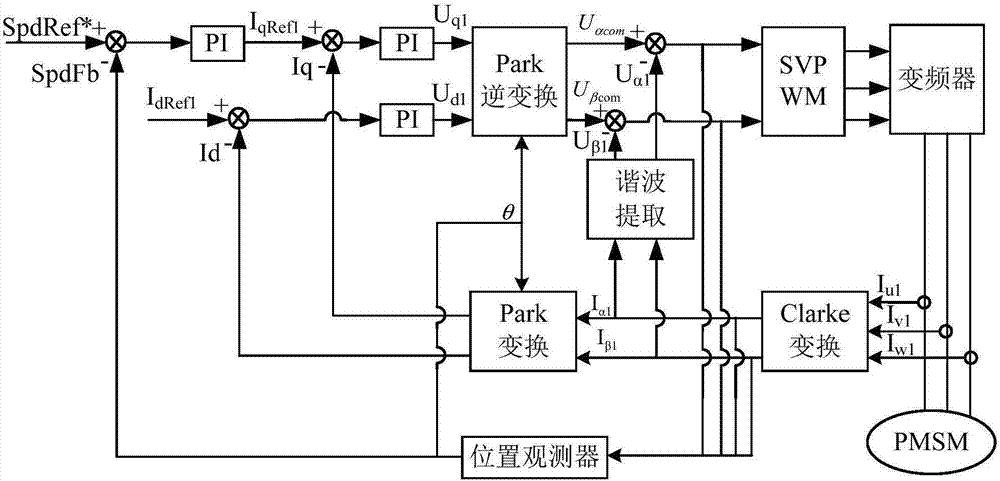

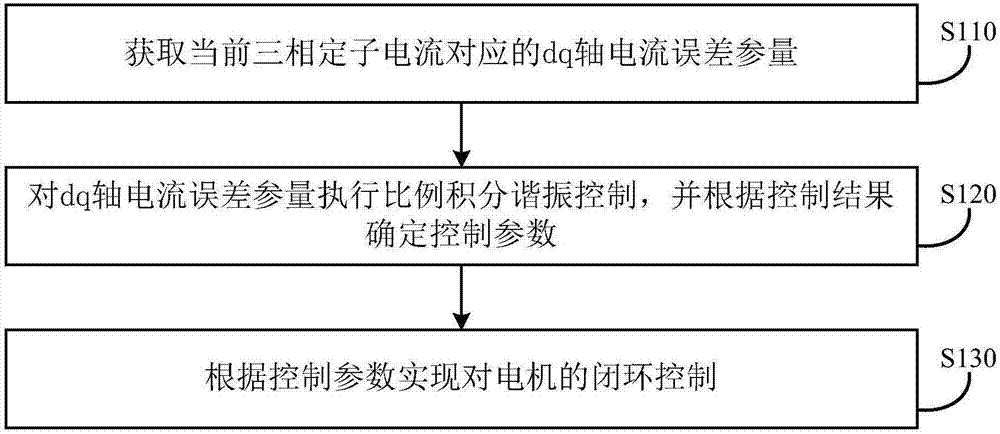

[0059] figure 2 It is a flow chart of a harmonic current suppression method provided by Embodiment 1 of the present invention. The harmonic current suppression method provided in this embodiment is applicable to the situation of suppressing harmonics in PMSM. The method for suppressing harmonic current provided in this embodiment may be executed by a device for suppressing harmonic current, which may be implemented in the form of software and / or hardware, and integrated into a device for suppressing harmonic current.

[0060] refer to figure 2 , the harmonic current suppression method provided in this embodiment specifically includes:

[0061] S110. Obtain dq-axis current error parameters corresponding to the current three-phase stator current.

[0062] Wherein, the motor in this embodiment is PMSM. Three-phase stator windings are used in PMSM, thus generating three-phase stator currents. In this embodiment, the three-phase stator currents are respectively used by I u ...

Embodiment 2

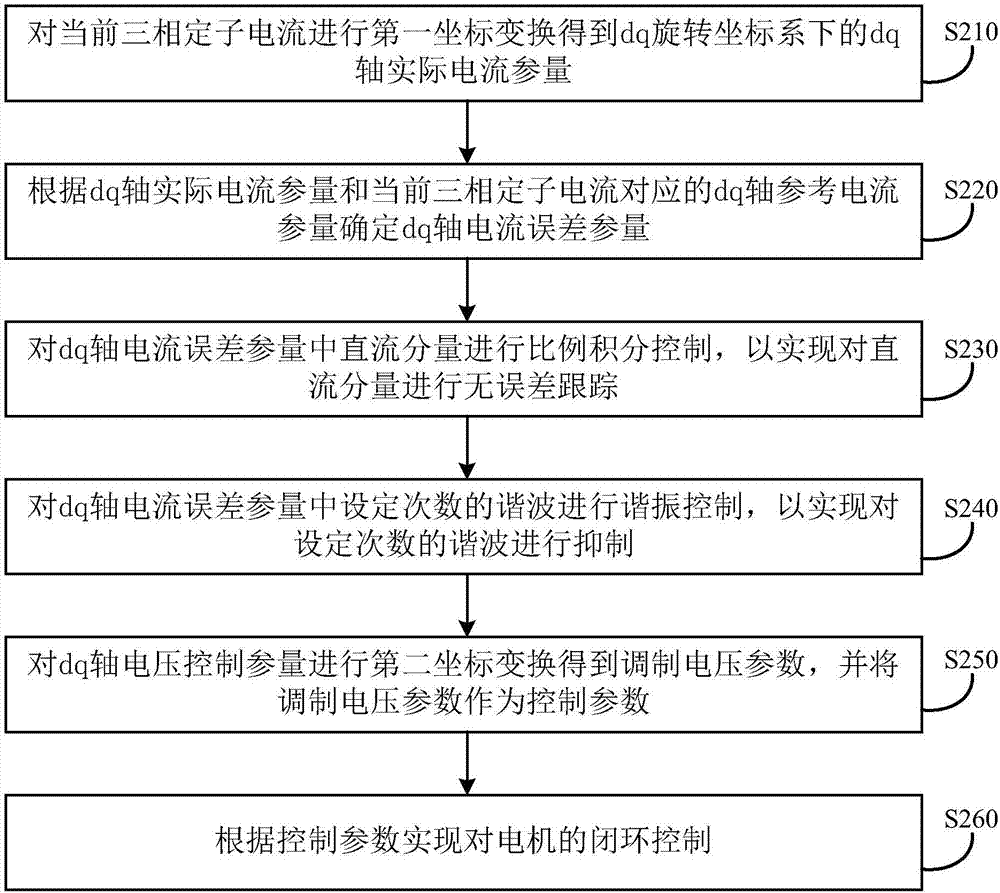

[0082] Figure 3a It is a flow chart of a harmonic current suppression method provided by Embodiment 2 of the present invention. This embodiment is embodied on the basis of the above-mentioned embodiments. Specifically, obtaining the dq-axis current error parameters corresponding to the current three-phase stator current includes: performing the first coordinate transformation on the current three-phase stator current to obtain the dq-axis actual current parameters in the dq rotating coordinate system; according to the dq-axis actual current parameters and the current The dq-axis reference current parameters corresponding to the three-phase stator currents determine the dq-axis current error parameters.

[0083] Further, performing proportional-integral resonance control on the dq-axis current error parameters includes: performing proportional-integral control on the DC component in the dq-axis current error parameter to realize error-free tracking of the DC component; settin...

Embodiment 3

[0136] Figure 4 It is a schematic structural diagram of a harmonic current suppression device provided by Embodiment 3 of the present invention. refer to Figure 4 , the harmonic current suppression device provided in this embodiment includes: an acquisition module 301 , a control module 302 and a closed-loop control module 303 .

[0137] Among them, the obtaining module 301 is used to obtain the dq axis current error parameter corresponding to the current three-phase stator current; the control module 302 is used to perform proportional integral resonance control on the dq axis current error parameter, and determine the control parameter according to the control result; closed-loop control Module 303, used to realize the closed-loop control of the motor according to the control parameters.

[0138] The technical solution provided in this embodiment obtains the dq-axis current error parameters corresponding to the three-phase stator currents, and performs proportional integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com