Non-fried instant noodles and preparation method thereof

A technology of non-fried instant noodles and oil, which is applied in the direction of food science, food preservation, and the function of food ingredients, etc., can solve the problems of long brewing time and single nutritional structure, and achieve short brewing time, rich nutrition, and nutritional structure Full and Rich Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

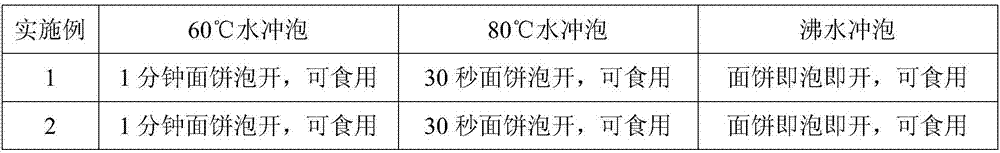

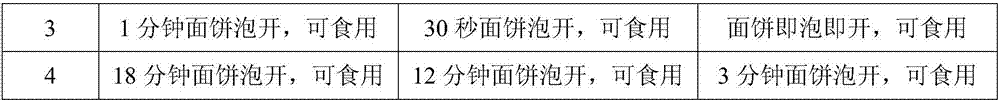

Examples

preparation example Construction

[0031] A kind of preparation method of non-fried instant noodles of the present invention specifically comprises the following steps:

[0032] Step 1: Prepare raw materials: take the raw materials by weight;

[0033] Step 2: mixing: adding water to the material and mixing evenly, so that the water content of the mixed material is 25-35%;

[0034] Step 3: ripening: ripening the mixed material at 30-50°C;

[0035] Step 4: Cutting into strips: Cutting and calendering the cured mixed material, and then shredding to obtain wet noodles;

[0036] Step 5: Drying and packaging: Freeze-dry the wet noodles, pack them, and get ready.

[0037] In the step 2, the water content of the mixed material is 30%.

[0038] The aging temperature in step 3 is 40° C., and the aging time is 1-2 hours.

Embodiment 1

[0040] A preparation of non-fried instant noodles.

[0041] The weight ratio of raw materials is: 78 parts of wheat starch, 40 parts of corn starch, 20 parts of mung bean powder, 21 parts of cornstarch, 25 parts of peanut powder, and 18 parts of pregelatinized starch.

[0042] Among them, the peanut powder is obtained after extracting oil by cold pressing process. All the above-mentioned raw materials are passed through a 180-mesh sieve.

[0043] The preparation method specifically comprises the following steps:

[0044] Step 1: Prepare materials: Weigh 78 parts of wheat starch, 40 parts of cornstarch, 20 parts of mung bean powder, 21 parts of cornstarch, 25 parts of peanut powder, and 18 parts of pregelatinized starch by weight;

[0045] Step 2: Mixing: add water to the above materials and mix evenly, so that the water content of the mixed materials is 30%;

[0046] Step 3: ripening: aging the mixed material at 40°C for 2 hours;

[0047] Step 4: Cutting into strips: Cutti...

Embodiment 2

[0050] A preparation of non-fried instant noodles.

[0051] The weight ratio of raw materials is: 60 parts of wheat starch, 50 parts of corn starch, 30 parts of mung bean powder, 25 parts of cornstarch, 15 parts of peanut powder, and 28 parts of pregelatinized starch.

[0052] Among them, the peanut powder is obtained after extracting oil by cold pressing process. All the above-mentioned raw materials are passed through a 180-mesh sieve.

[0053] The preparation method specifically comprises the following steps:

[0054] Step 1: Prepare materials: take by weight 60 parts of wheat starch, 50 parts of corn starch, 30 parts of mung bean powder, 25 parts of cornstarch, 15 parts of peanut powder, and 28 parts of pregelatinized starch;

[0055] Step 2: Mixing: add water to the above materials and mix evenly, so that the water content of the mixed materials is 25%;

[0056] Step 3: ripening: aging the mixed material at 50°C for 1 hour;

[0057]Step 4: Cutting into strips: Cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com