Fine-fraction roasting iron ore full-sealing dry waste-discarding process

A fully-sealed, fine-grained technology, applied in the field of mineral processing, can solve the problems of waste of resources, rising grinding costs, and large dust, and achieve the effect of avoiding waste of resources, reducing grinding costs, and good waste disposal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

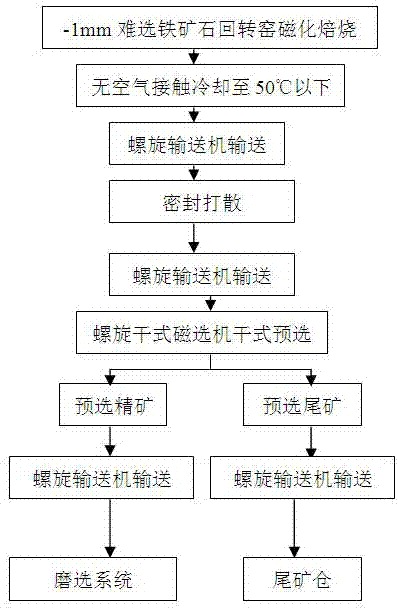

[0013] The refractory iron ore specular iron ore powder ore with a grade of 32% in Jiuquan Iron and Steel Group is subjected to a fully sealed dry-type discarding process, including the following steps:

[0014] A. The specularite powder ore with a particle size of -1mm is granulated and magnetized and roasted at a temperature of 700°C in a rotary kiln, then cooled to 50°C without air contact, and transported by a screw conveyor to a dispersing device for dispersing.

[0015] B. After breaking up, the screw conveyor is sent to the screw dry magnetic separator for fully sealed dry pre-selection and discarding operation. The discarding yield and taste can be controlled by the speed of the screw dry magnetic separator, and the discarding yield is 10%. , The pre-selected tailings with a discarded grade of 7.8% passed the dry separation test of the roasted ore after discarded in the laboratory, and the waste rock content was only 0.2%, and the grade of the dry pre-selected tailings ...

Embodiment 2

[0018] The refractory iron ore hematite powder ore with a grade of 33% in Jiuquan Iron and Steel Group is subjected to a fully sealed dry-type discarding process, including the following steps:

[0019] A. Hematite powder ore with a particle size of -1mm is granulated and magnetized and roasted at a temperature of 650°C in a rotary kiln, then cooled to 45°C without air contact, and transported by a screw conveyor to a dispersing device for dispersing.

[0020] B. After breaking up, the screw conveyor is sent to the screw dry magnetic separator for fully sealed dry pre-selection and discarding operation. The discarding yield and taste can be controlled by the speed of the screw dry magnetic separator, and the discarding yield is 9%. , The pre-selected tailings with a discarded grade of 7.4% passed the dry separation test of the roasted ore after discarded in the laboratory, and the waste rock content was only 0.18%, and the grade of the dry pre-selected tailings met the requirem...

Embodiment 3

[0023] The fully-sealed dry throwing process of refractory iron ore complex paragenetic iron ore powder ore with a grade of 32% in Jiuguan Iron and Steel Group includes the following steps:

[0024] A. The complex symbiotic iron ore powder ore with a particle size of -1mm is granulated and magnetized and roasted at a temperature of 750°C in a rotary kiln, then cooled to 40°C without air contact, and transported by a screw conveyor to a dispersing device for dispersing.

[0025] B. After breaking up, the screw conveyor is sent to the screw dry magnetic separator for fully sealed dry pre-selection and discarding operation. The discarding yield and taste can be controlled by the speed of the screw dry magnetic separator, and the discarding yield is 9.6%. , The pre-selected tailings with a discarded grade of 7.5% passed the laboratory dry separation test of the roasted ore after discarded, and the waste rock content was only 0.21%, and the grade of the dry pre-selected tailings met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com