Solvent-controlled full-color-emitting copper cluster assembly fluorescent material and preparation method thereof, and application of fluorescent material to white LED devices

A fluorescent material and solvent regulation technology, which is applied in the direction of luminescent materials, semiconductor devices, chemical instruments and methods, etc., can solve the problems of energy transfer, weak luminescence of fluorescent powder, and difficult manufacturing process, and achieve low copper toxicity and green synthesis method , Experiment simple and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

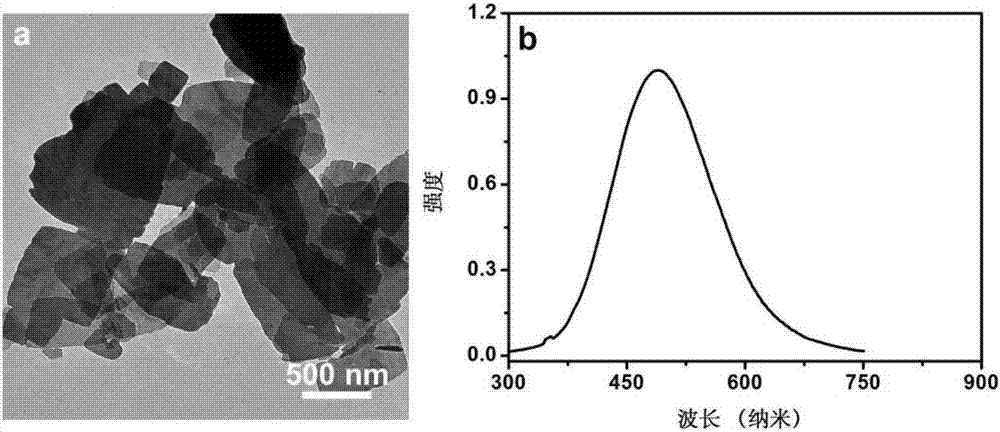

[0028] Add 200 μL of n-hexane and dissolve 0.06 mmol of CuCl in a 25 mL single-necked bottle 2 2H 2 O, ultrasonically dissolve the copper source completely, add 10mL of liquid paraffin, under magnetic stirring at room temperature, add 1.2mmol of octyl mercaptan, ultrasonically mix evenly, and then keep stirring at room temperature for 30min. Pour 10mL of the reacted solution into a 100mL centrifuge tube, add 20mL of dichloromethane and 40mL of ethanol successively, shake well, and centrifuge at 3000r / min for 3min; repeat the centrifugation operation of the above product three times with the same steps, and drain the product to obtain Thiol-stabilized copper nanocluster sheet assembly materials, such as figure 1 As shown, it is a blue fluorescent powder with a fluorescence peak at 490nm.

Embodiment 2

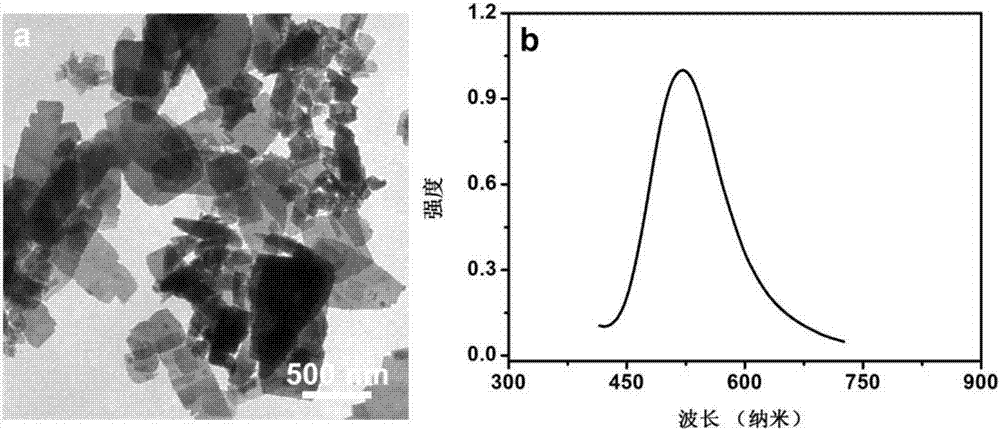

[0030] Add 200 μL of acetonitrile and dissolve 0.06 mmol of CuCl in a 25 mL single-necked bottle 2 2H 2 O, ultrasonically dissolve the copper source completely, add 10mL of liquid paraffin, under magnetic stirring at room temperature, add 1.2mmol of octyl mercaptan, ultrasonically mix evenly, and then keep stirring at room temperature for 30min. Pour 10mL of the reacted solution into a 100mL centrifuge tube, add 20mL of dichloromethane and 40mL of ethanol successively, shake well, centrifuge at 3000r / min for 3min, repeat the centrifugation operation of the above product three times with the same steps, and drain the product to obtain Thiol-stabilized copper nanocluster sheet assembly materials, such as figure 2 As shown, it is a green fluorescent powder with a fluorescence peak at 521nm.

Embodiment 3

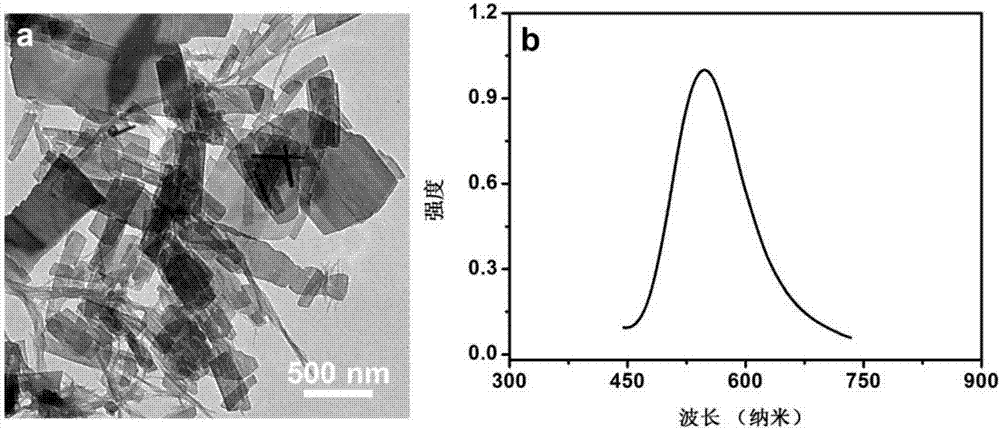

[0032] Add 200 μL of ethanol and dissolve 0.06 mmol of CuCl in a 25 mL single-necked bottle 2 2H 2 O, ultrasonically dissolve the copper source completely, add 10mL of liquid paraffin, under magnetic stirring at room temperature, add 1.2mmol of octyl mercaptan, ultrasonically mix evenly, and then keep stirring at room temperature for 30min. Pour 10mL of the reacted solution into a 100mL centrifuge tube, add 20mL of dichloromethane and 40mL of ethanol successively, shake well, centrifuge at 3000r / min for 3min, repeat the centrifugation operation of the above product three times with the same steps, and drain the product to obtain Thiol-stabilized copper nanocluster sheet assembly materials, such as image 3 As shown, it is a yellow-green fluorescent powder with a fluorescence peak at 548nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com