Fiber spinning and winding processing structure

A fiber and winding head technology, applied in the field of fiber textile winding processing structure, can solve the problems of automatic alarm and other problems, and achieve the effect of increasing intelligent control ability, stable and continuous maintenance, and expanding production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

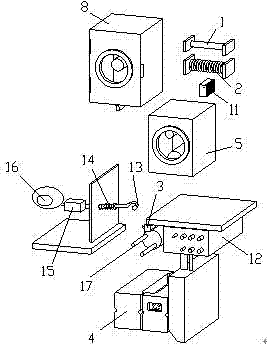

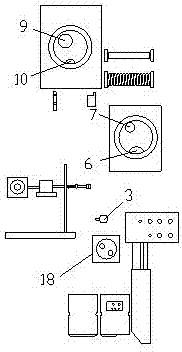

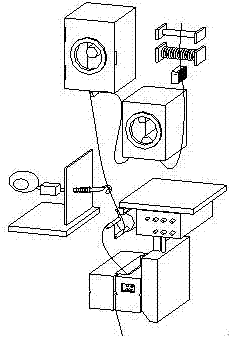

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0019] Please refer to the attached Figures 1 to 3 , the embodiment of the present invention includes:

[0020] A fiber textile winding processing structure, the tow first passes through the wire pressing rod 1 in the winding room, the wire pressing rod 1 makes the tow tense, and then enters the pre-network nozzle 2 to be processed by high-speed air flow and intertwined; after winding The tow enters the first wire roller mechanism after being sorted by the splitting comb 11. The first wire roller mechanism includes the first heat roller 6 and the first separation roller 7 in the first incubator. The first heat roller 6 and the first separation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com