A kind of deep hole etching method of sic-based gan crystal

A crystal and deep hole technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of etching rate, hole uniformity that is difficult to meet process requirements, and difficult to effectively control device warpage. , to achieve the effect of good controllability, weak metal erosion and uniform etching in the hole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solutions and advantages of the present application clearer, the present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. For the sake of simplicity, some technical features known to those skilled in the art are omitted from the following description.

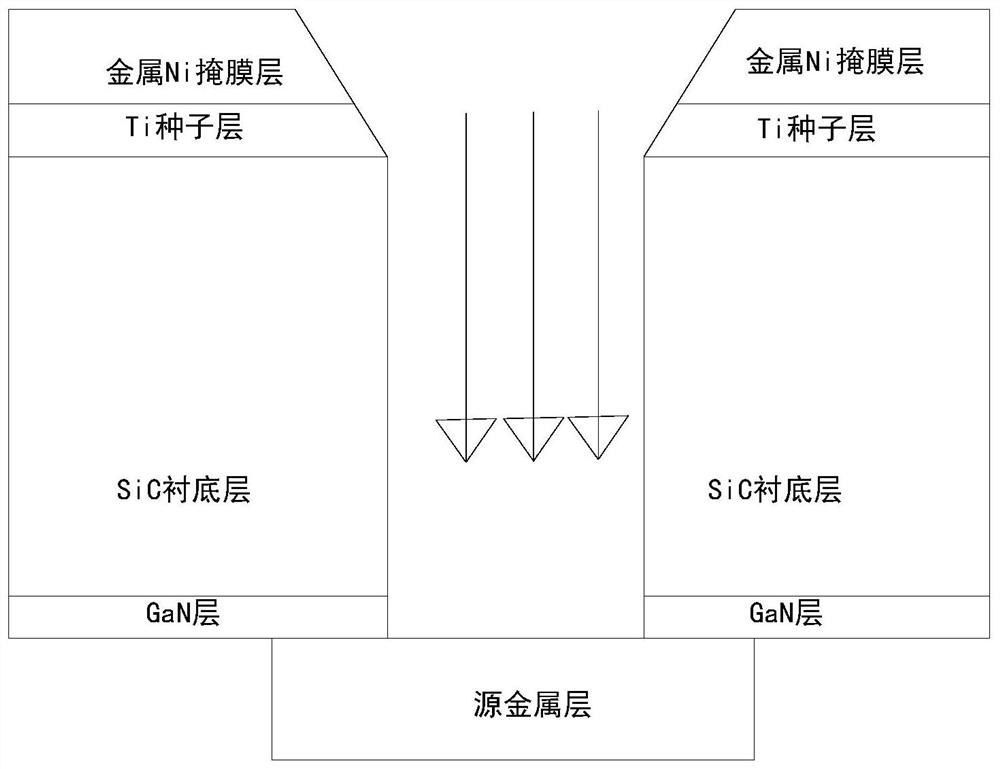

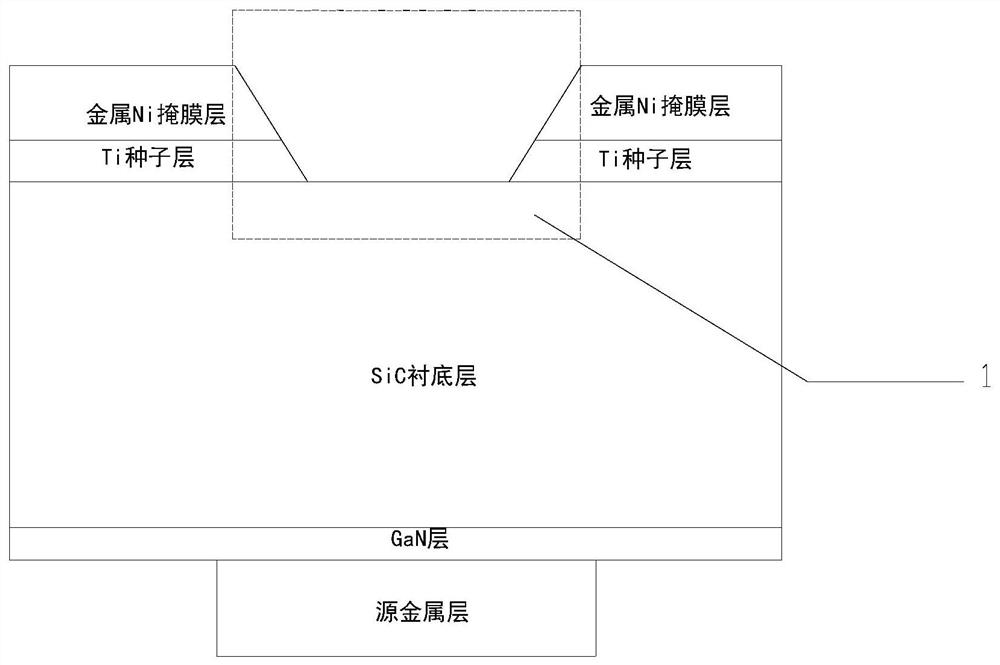

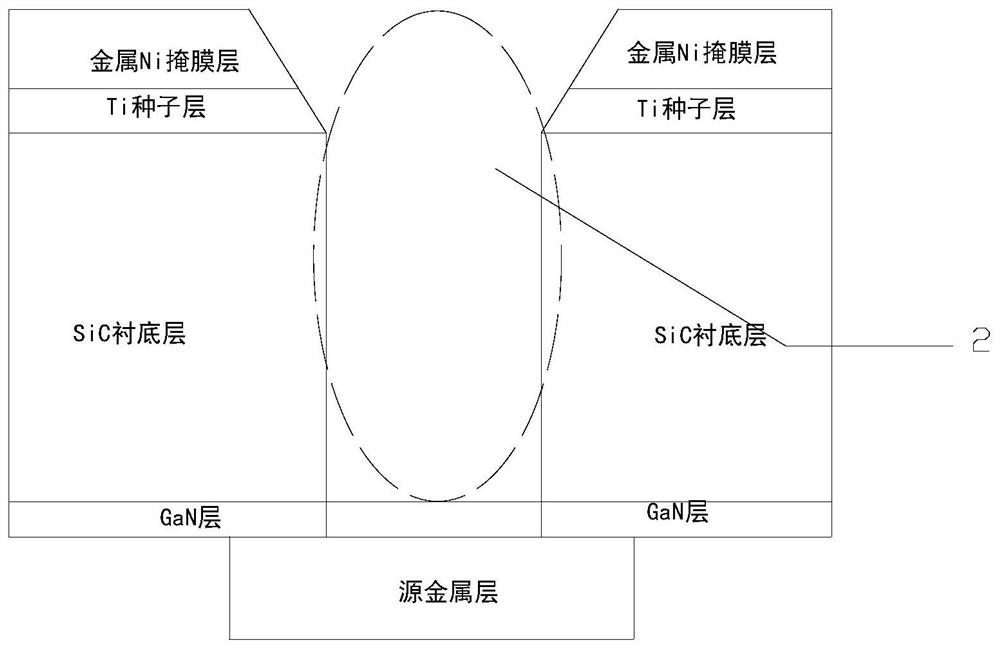

[0031] See Figure 1 to Figure 6 , a deep hole etching method for SiC-based GaN crystals, SiC-based GaN crystals (see figure 1 ) from bottom to top are the SiC substrate layer, GaN layer, and source metal layer. The deep hole etching is to perform dry etching on the SiC substrate layer and the GaN layer to form the back hole of the SiC-based GaN crystal. The complete etching steps (see Figure 5 )as follows:

[0032] S1: Pre-etching treatment, mechanically grind the SiC substrate layer to thin it to 90um-110μm, and then photolithography and deposit Ti on the back of the SiC substrate layer, thereby formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com