Soft light brick surface glaze and soft light brick

A technology of soft light tiles and soft light tiles, which is applied in the field of ceramic glazes and ceramic tiles, which can solve the problems of large differences, poor control of the gloss of soft light tiles, uneven gloss on the surface of tiles, etc., and achieve the effect of bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A kind of soft light brick surface glaze, calculated by weight, comprising: 52 parts of frit, 8 parts of kaolin, 20 parts of potassium feldspar, 10 parts of wollastonite, 2 parts of dolomite, 8 parts of zirconium silicate, 1 part of zinc oxide parts, 60 parts of water.

[0046] Wherein, the frit is composed of the following mass fractions: 50% silicon oxide, 15% aluminum oxide, 8% zinc oxide, 6% barium oxide, 14% calcium oxide, Magnesium oxide 6%, potassium oxide 0.5%, sodium oxide 0.5%.

[0047] The components of the soft light tile surface glaze are crushed and put into a ball mill according to the ratio to grind for 40 minutes, the fineness and viscosity are tested, and if they are qualified, they are filtered and the filtrate is collected to obtain the finished soft light tile surface glaze.

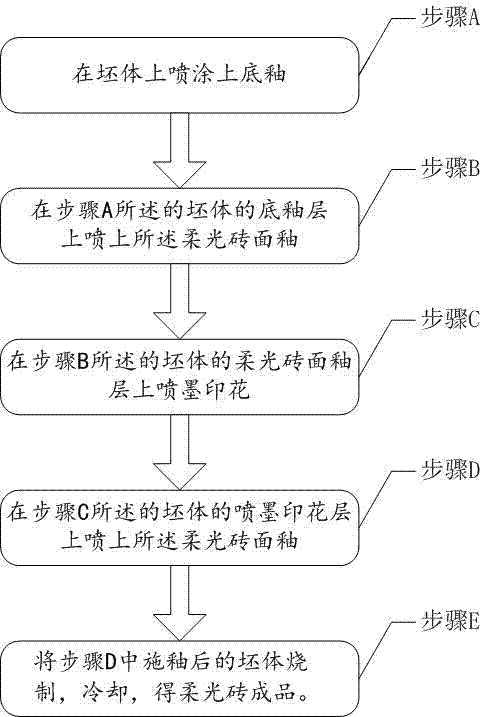

[0048] Use the surface glaze of the soft light brick to make soft light bricks, and the production process of the soft light bricks includes the following steps:

[0049] A....

Embodiment 2

[0055] A kind of soft light brick surface glaze, calculated by weight, comprising: 50 parts of frit, 15 parts of kaolin, 32 parts of potassium feldspar, 16 parts of wollastonite, 3 parts of dolomite, 12 parts of zirconium silicate, 3 parts of zinc oxide parts, 52 parts of water.

[0056] Wherein, the frit is composed of the following mass fractions: 50% silicon oxide, 15% aluminum oxide, 8% zinc oxide, 6% barium oxide, 14% calcium oxide, Magnesium oxide 6%, potassium oxide 0.5%, sodium oxide 0.5%.

[0057] The components of the soft light tile surface glaze are crushed and put into a ball mill according to the ratio to grind for 40 minutes, the fineness and viscosity are tested, and if they are qualified, they are filtered and the filtrate is collected to obtain the finished soft light tile surface glaze.

[0058] Use the surface glaze of the soft light brick to make soft light bricks, and the production process of the soft light bricks includes the following steps:

[0059]...

Embodiment 3

[0065] A kind of soft light brick surface glaze, calculated by weight, comprising: 60 parts of frit, 20 parts of kaolin, 35 parts of potassium feldspar, 20 parts of wollastonite, 5 parts of dolomite, 15 parts of zirconium silicate, 5 parts of zinc oxide part, 80 parts of water.

[0066] Wherein, the frit is composed of the following mass fractions: 50% silicon oxide, 15% aluminum oxide, 8% zinc oxide, 6% barium oxide, 14% calcium oxide, Magnesium oxide 6%, potassium oxide 0.5%, sodium oxide 0.5%.

[0067] The components of the soft light tile surface glaze are crushed and put into a ball mill according to the ratio to grind for 40 minutes, the fineness and viscosity are tested, and if they are qualified, they are filtered and the filtrate is collected to obtain the finished soft light tile surface glaze.

[0068] Use the surface glaze of the soft light brick to make soft light bricks, and the production process of the soft light bricks includes the following steps:

[0069] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap