A method for waterproof sealing of pipe gallery deformation joints

A technology of waterproof sealing and deformation joints, applied in water conservancy projects, underwater structures, buildings, etc., can solve problems such as easy to fall off or tear, difficult to replace, pollute the environment, etc., to achieve excellent aging resistance and weather resistance, Improve overall construction efficiency and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

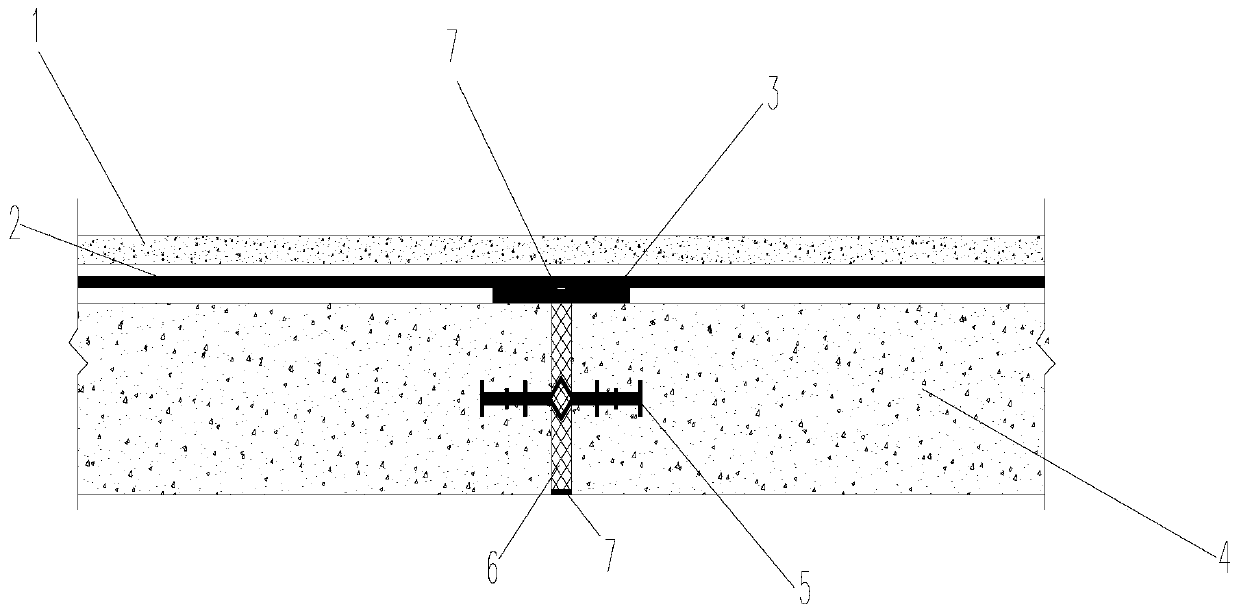

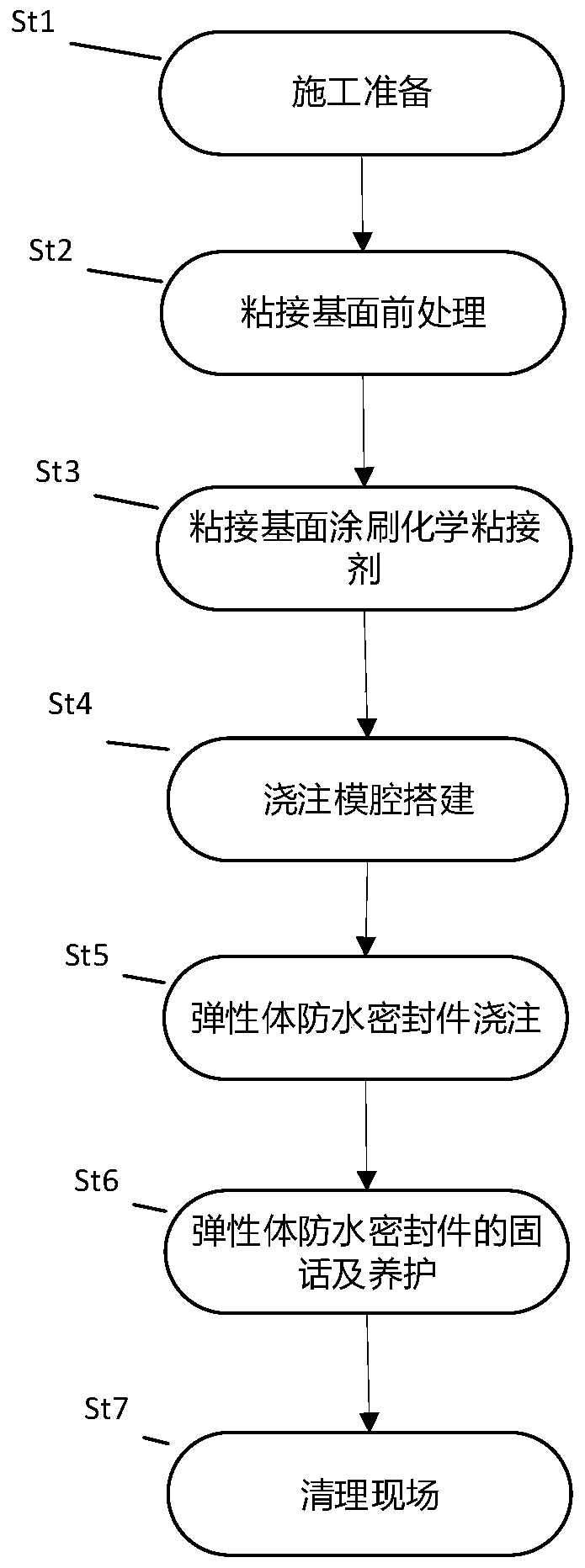

[0049] Such as Figure 2~3 As shown, the present invention discloses a method for waterproof sealing of deformation joints of pipe gallery, the steps of which include:

[0050] St1: construction preparation;

[0051] St2: Pre-treatment of bonding base;

[0052] St3: Apply chemical adhesive to the bonding base surface;

[0053] St4: Casting cavity construction;

[0054] St5: pouring of elastomer waterproof seals;

[0055] St6: Fixing and maintenance of elastomer waterproof seals;

[0056] St7: Clean up the scene.

[0057] In the steps of the method for waterproofing and sealing the deformation joints of the pipe gallery according to the present invention, in step St2, the pre-adhesive treatment of the bonding base is mainly to remove the pre-embedded foam board, bond the weak interface on the surface of the cast-in-place concrete, and remove holes and numbness. surface, etc., including the removal and grinding of the pre-embedded foam boards in the deformation joints, the...

Embodiment 2

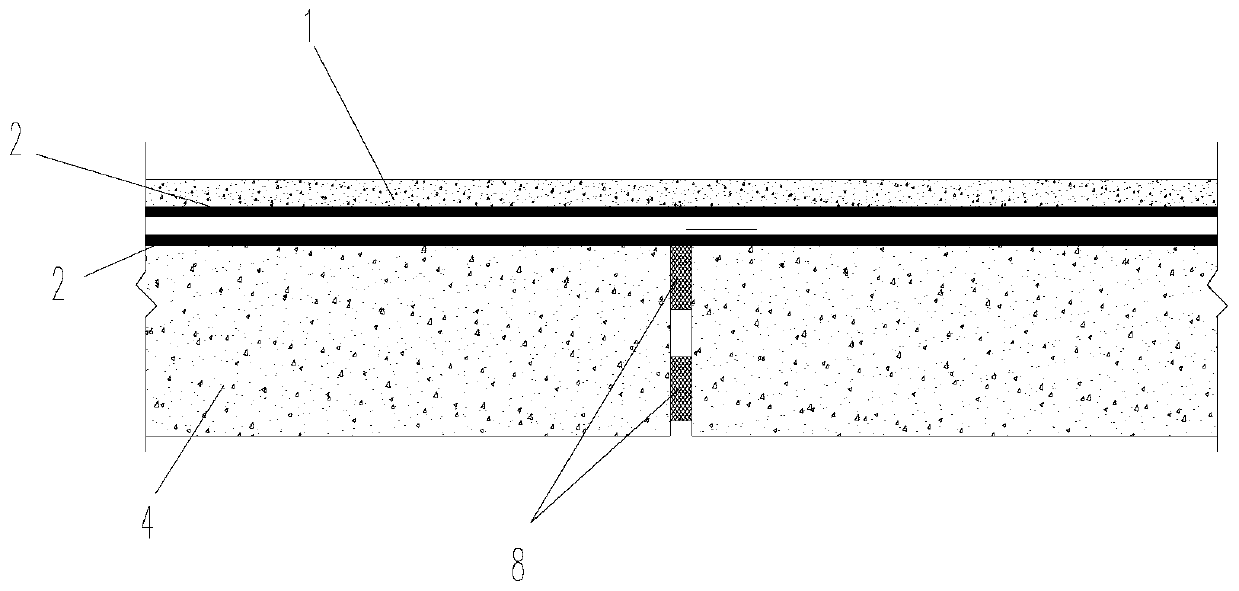

[0071] As an embodiment of the present invention, such as Figure 4 As shown, in the step St2 bonding base treatment, after the concrete base surface treatment, add the step St21 beam joint inspection, by checking whether the concrete water content between the deformation joints of the pipe gallery is less than 25%, if so, go to step St3 Apply chemical adhesive to the bonding base surface; if not, dry the deformation joints of the pipe gallery, and then transfer to the step of St21 beam joint inspection until the concrete water between the deformation joints of the pipe gallery is less than 25%, enter step St3 to apply chemical adhesive on the bonding base surface.

[0072] This setting further ensures the reliability of the bonding surface between the elastic body waterproof seal 8 and the concrete 4 , and ensures the durability and shear resistance of the bond between the elastic body waterproof seal 8 and the concrete 4 .

Embodiment 3

[0074] As an embodiment of the present invention, such as Figure 5 As shown, compared with Example 2, before applying the chemical adhesive on the bonding base surface in step St3, the process of grinding the deformation joints of St23 is added to polish the deformation joints of the pipe gallery, and then enter the step St3 bonding base surface Apply chemical adhesive. This setting makes the surface of the treated concrete base should be flat, clean, and dry without hollowing, looseness, honeycomb pitting, scum, floating soil, release agent, oil and other dirt. This setting is more conducive to elastomer waterproof seals 8. Better adhesion between chemical adhesive and concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com