Sealing gasket for plate heat exchanger

A technology of plate heat exchangers and sealing gaskets, which is applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve problems affecting and restricting the survival and development of enterprises, and limiting the application range of plate heat exchangers. Achieve high sealing performance, limited rebound rate and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

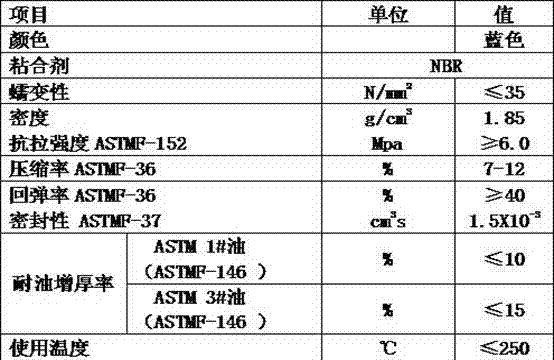

[0015] A sealing gasket for a plate heat exchanger of the present invention uses relatively high content of aramid fibers and artificial rock wool (sepiolite) as reinforcing materials (i.e. fillers), and uses natural rubber, styrene-butadiene or NBR is used as the adhesive, organic and inorganic fibers are used as the frame, and the sheet is specially made by rolling method, that is, NY4250 oil-resistant and asbestos-free rubber sheet. The sheet is 100% asbestos-free and has excellent comprehensive performance. The prepared NY4250 oil-resistant asbestos-free rubber sheet with a thickness of 3.6 mm is laser cut into a shape corresponding to the sealing groove of the sheet, which is the sealing gasket of the present invention. Its main technical characteristics are shown in Table 1 below:

[0016] Table 1 Main technical characteristics of oil-resistant and asbestos-free rubber gaskets

[0017]

[0018] The sealing gasket of the present invention has superior temperature resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com