Thermal spraying insulating coating and preparation method thereof

A technology of insulating coating and thermal spraying, which is applied to coatings, devices for coating liquid on the surface, special surfaces, etc., can solve problems such as difficulty in bearing high-speed loads, poor bonding strength, and low withstand voltage strength, and achieve improved insulation Good strength, good insulation performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

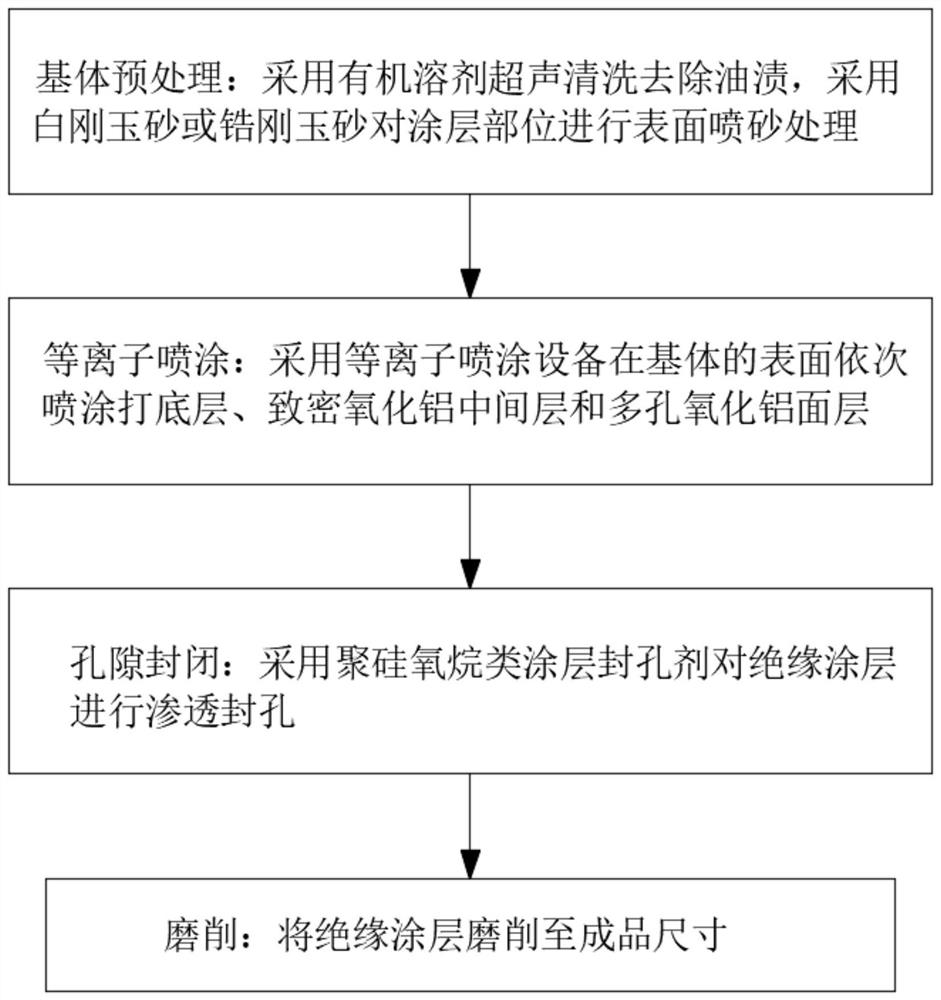

[0025] The present invention provides such figure 1 A kind of thermal spraying insulating coating, thermal spraying insulating coating comprises, primer layer, dense aluminum oxide middle layer and porous alumina surface layer, primer layer is positioned at the surface of substrate, and primer layer is formed by plasma spraying process, and its thickness is 50μm;

[0026] The dense alumina intermediate layer is arranged on the surface of the primer layer, and the dense alumina intermediate layer is formed by a plasma spraying process with fine-grained alumina powder, and its thickness is 100 μm. Among them, the dense alumina intermediate layer adopts 10-30 μm Aluminum powder as raw material;

[0027] The porous alumina surface layer is arranged on the outer surface of the dense alumina intermediate layer, and the porous alumina surface layer is formed by plasma spraying process with coarse-grained alumina powder, and its thickness is 200 μm. Among them, the porous alumina sur...

Embodiment 2

[0046]The difference with embodiment 1 is that a kind of thermal spraying insulation coating, thermal spraying insulation coating comprises, primer layer, compact aluminum oxide intermediate layer and porous alumina surface layer, primer layer is positioned at the surface of substrate, and primer layer nickel The thickness of chromium molybdenum is 75μm;

[0047] The dense alumina intermediate layer is arranged on the surface of the primer layer, and the dense alumina intermediate layer is formed by a plasma spraying process of fine-grained alumina powder, and its thickness is 150 μm. Among them, the dense alumina intermediate layer is 5-22 μm oxide Aluminum powder as raw material;

[0048] The porous alumina surface layer is arranged on the outer surface of the dense alumina intermediate layer, and the porous alumina surface layer is formed by a plasma spraying process with coarse-grained alumina powder, and its thickness is 500 μm. Among them, the porous alumina surface laye...

Embodiment 3

[0052] The difference with embodiment 1 is that a kind of thermal spraying insulation coating, thermal spraying insulation coating comprises, primer layer, compact aluminum oxide intermediate layer and porous alumina surface layer, primer layer is positioned at the surface of substrate, and primer layer nickel Aluminum clad thickness is 100μm;

[0053] The dense alumina intermediate layer is arranged on the surface of the base layer, and the dense alumina intermediate layer is formed by a plasma spraying process with fine-grained alumina powder, and its thickness is 100 μm. Among them, the dense alumina intermediate layer is 5-22 μm oxide Aluminum powder as raw material;

[0054] The porous alumina surface layer is arranged on the outer surface of the dense alumina intermediate layer, and the porous alumina surface layer is formed by plasma spraying process with coarse-grained alumina powder, and its thickness is 1000 μm. Among them, the porous alumina surface layer is made of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com