Thermal spraying ceramic insulating coating and preparation method thereof

A technology of ceramic insulation and thermal spraying, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of low withstand voltage, difficult to bear high-speed load, poor bonding strength, etc., to achieve good product quality, Low production cost, excellent insulation and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

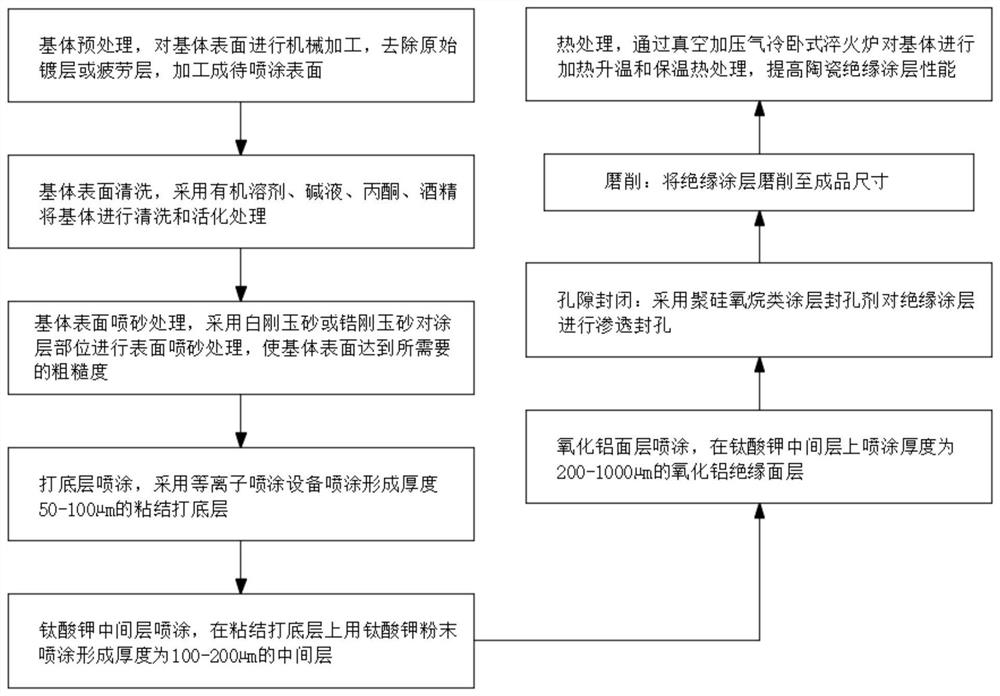

Method used

Image

Examples

Embodiment 1

[0031] The invention provides a thermal spraying ceramic insulating coating, the thermal spraying ceramic insulating coating comprises a primer layer, a potassium titanate intermediate layer and an aluminum oxide surface layer, the primer layer is located on the outer surface of the substrate, the titanium The potassium oxide intermediate layer is located on the bottom layer, and the alumina surface layer is located on the potassium titanate intermediate layer;

[0032] The bottom layer is formed by plasma spraying process, and its thickness is 50-100 μm;

[0033] The intermediate layer is formed of potassium titanate powder by plasma spraying process, and its thickness is 100-200 μm;

[0034] The surface layer is formed from alumina powder by plasma spraying process, and its thickness is 200-1000 μm.

[0035] Wherein, the primer layer is set to be one of nickel-chromium-molybdenum composite powder, nickel-clad aluminum, nickel-chromium-aluminum composite powder and molybdenu...

Embodiment 2

[0052] The difference from Example 1 is that 24 mesh zirconium corundum is used for sandblasting, and the surface roughness is Ra=8μm; the bottom layer is sprayed with nickel-chromium-molybdenum composite powder with a thickness of 50μm; Potassium powder is sprayed with a thickness of 100μm; the thickness of the insulating surface layer is 200μm.

[0053] The insulation performance is: withstand voltage 2500V, resistance value> 200ΩM; bonding strength 65MPa.

Embodiment 3

[0055] The difference from Example 1 is that the roughness of the surface is Ra=10 μm; the thickness of the base layer is 75 μm; the thickness of the intermediate layer potassium hexatitanate is 150 μm; the thickness of the insulating surface layer is 500 μm.

[0056] The insulation performance is: withstand voltage 6400V, resistance value> 200ΩM; bonding strength 61MPa.

[0057] To sum up: the present invention uses potassium titanate as the filter layer, which can form a completely dense coating structure, preventing corrosion or electrolyte from entering the interior of the coating; the good heat insulation performance of potassium titanate can prevent frictional heat from being conducted to the substrate; using Neutral alumina sol or neutral silica sol can replace epoxy resin or silicone sealing agent, which has better insulation and temperature resistance; the ceramic insulating coating structure prepared by the preparation method of thermal spraying ceramic insulating coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com