A system and method for off-line chemical cleaning of mbr membrane units on-line

A technology of chemical cleaning and membrane assembly, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of increasing the construction cost of sewage treatment plants, increasing the operating costs of sewage treatment plants, and long cleaning time, etc. Achieve the effects of saving manpower, reducing construction costs and operating costs, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

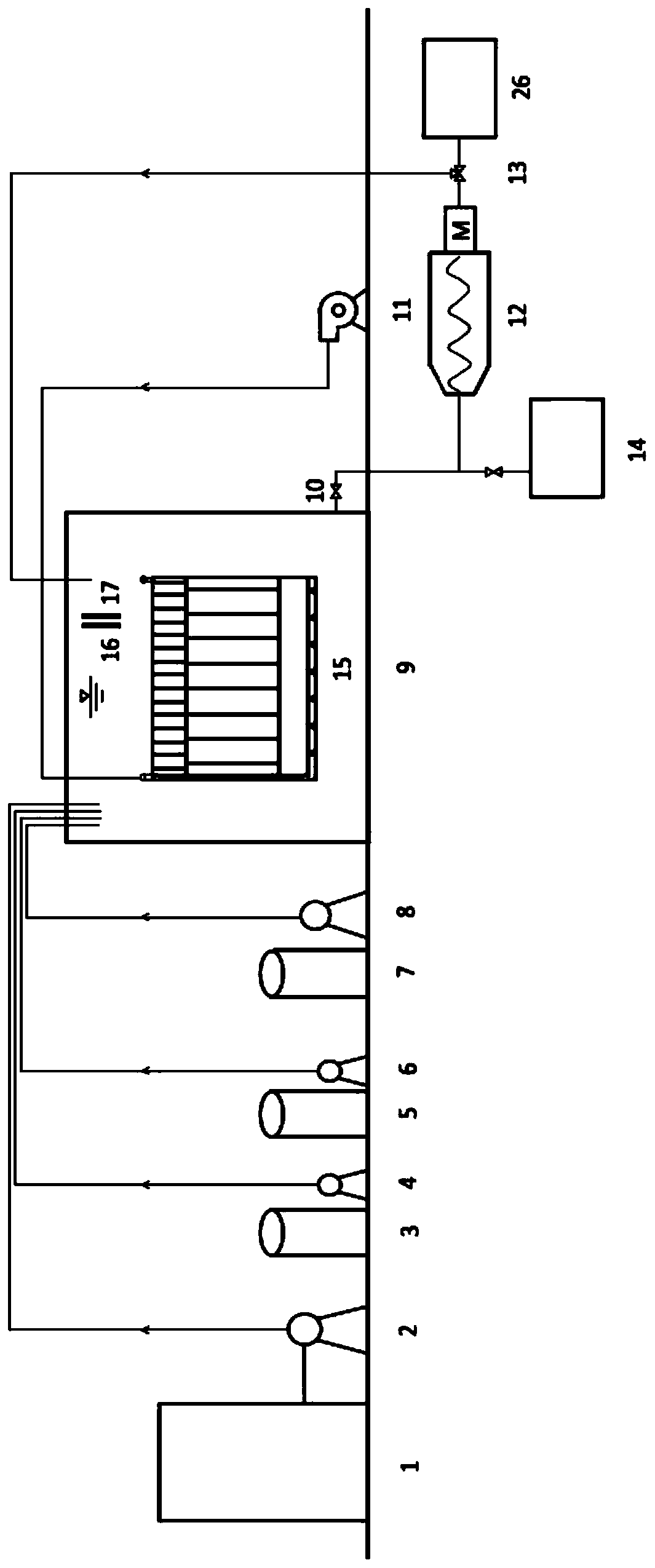

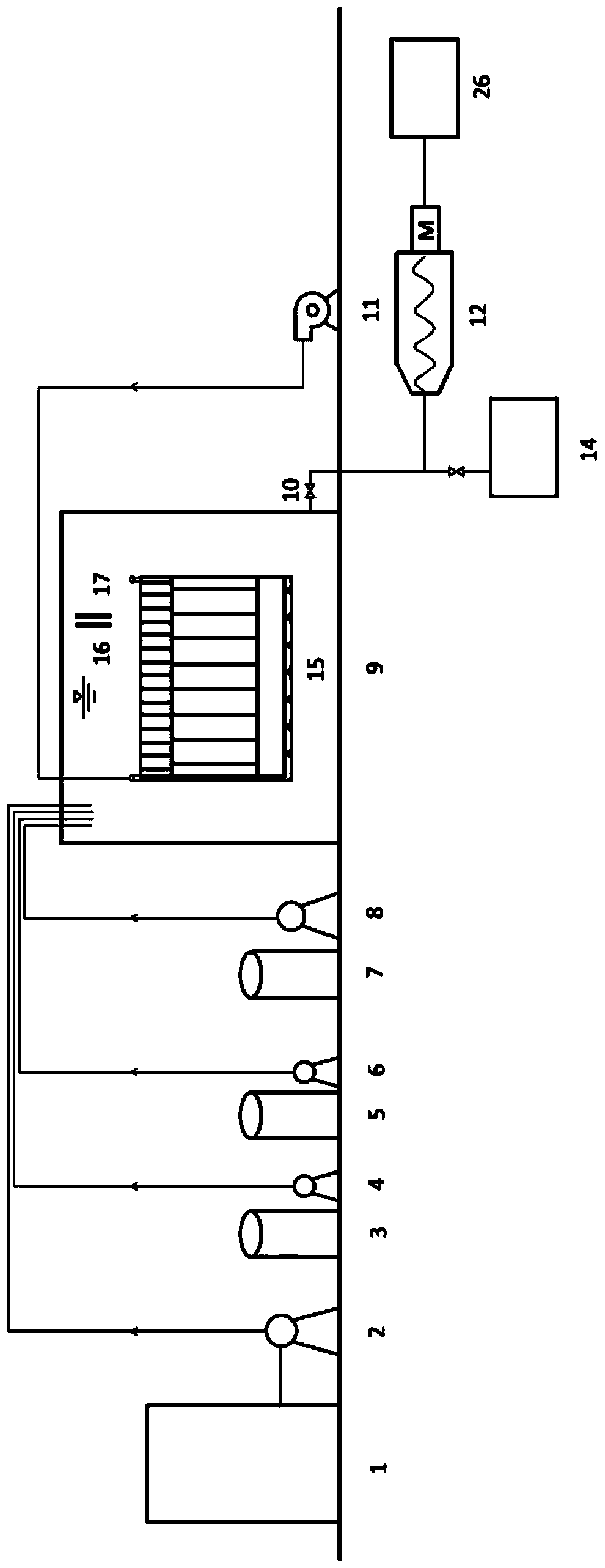

[0058] combined with figure 1 To illustrate the cleaning of an MBR corridor:

[0059] The muddy water in the 1#MBR corridor 9 is emptied to the coarse grid well 14 through the vent valve 10, and then the clean water in the reclaimed water reuse tank 1 is filled with the clean water in the reclaimed water reuse tank 1 with the backwash pump 2, and the 1#MBR corridor is air-exposed for 48 hours to remove the MBR Part of the mud cake on the surface of the membrane is emptied; continue to pour water to the specified level, then add sodium hypochlorite solution, aerate while adding medicine, when the concentration of sodium hypochlorite reaches 3000-5000ppm, pH = 12-12.5, carry out static soaking for 20 hours, Carry out aeration for another 15 minutes; then open the vent valve 10, and empty the sodium hypochlorite medicinal solution to the coarse grid well; inject clear water into the 1#MBR corridor 9 several times until the pH is neutral, and then vent; then use the dosing system...

Embodiment 2

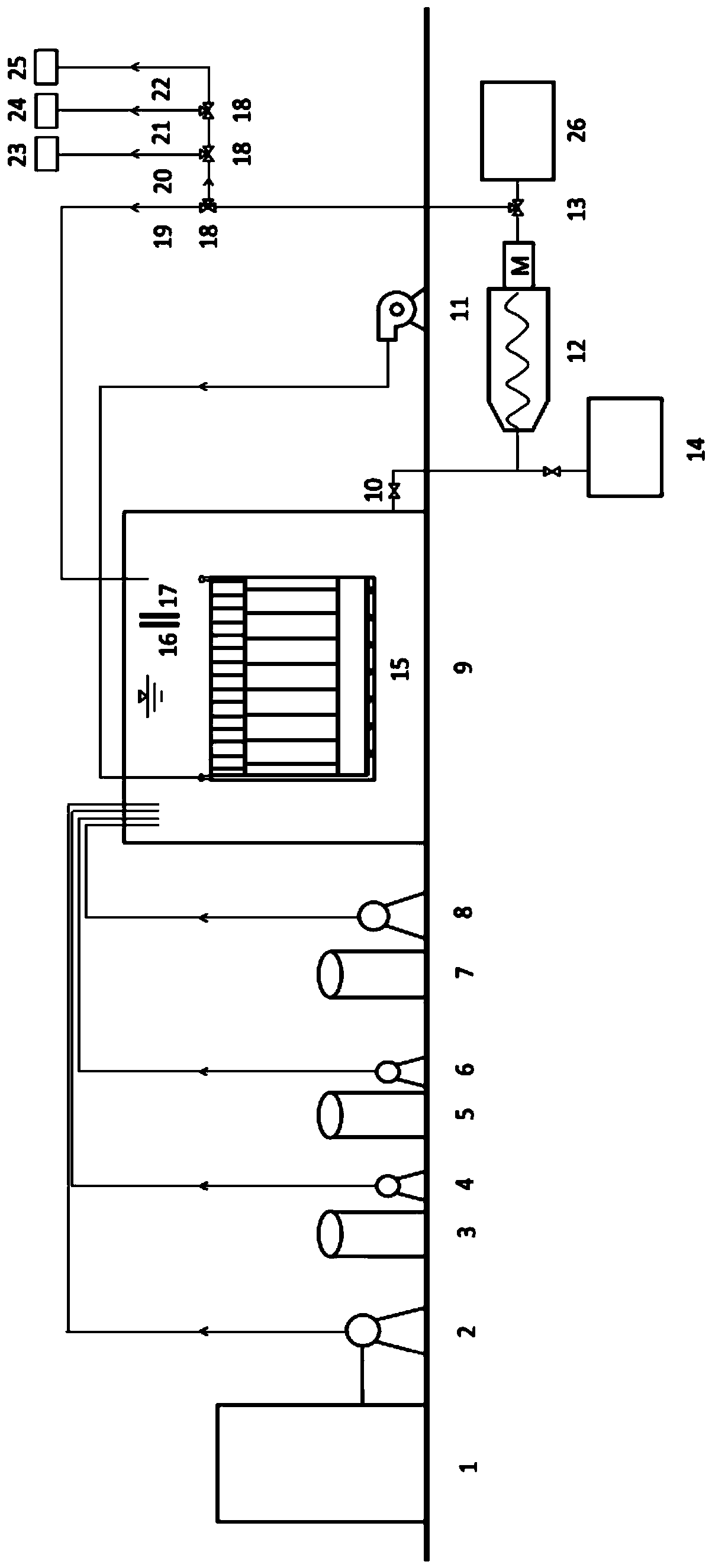

[0061] combined with image 3 To illustrate the cleaning of the four MBR corridors:

[0062] Vent the muddy water that needs to be cleaned in the 1#MBR corridor 9 to the coarse grid well 14 through the vent valve 10, and then use the backwash pump 2 to fill the 1#MBR corridor with clear water for 48 hours. Remove part of the mud cake on the surface of the MBR membrane and empty it; continue to pour water to the specified level, then add sodium hypochlorite solution, aerate while adding medicine, when the concentration of sodium hypochlorite reaches 3000-5000ppm, pH = 12-12.5, carry out static soaking 20h, then carry out aeration for 15min; then use the remaining sludge pump 12 to pump the sodium hypochlorite liquid through the three-way main valve 13, the three-way valve 18 and the pipeline 20 leading to the 2#MBR corridor to another 2#MBR that needs to be cleaned Corridor 23 is cleaned, and 5% of the sodium hypochlorite dosage is added, and the cleaning method is the same as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com