PC/ABS alloy with noise reduction performance and preparation method of PC/ABS alloy

A noise reduction and high performance technology, which is applied in the field of PC/ABS alloy with noise reduction performance and its preparation, can solve the problems of constraints and complex structure parts that cannot be well applied, so as to improve applicability and physical Mechanical properties, the effect of improving the phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

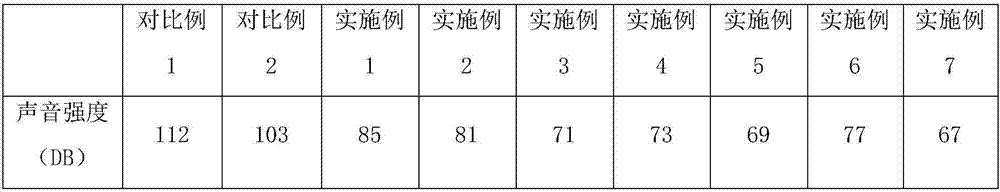

Examples

Embodiment 1

[0056] The present embodiment provides a kind of PC / ABS alloy with noise-reducing performance, and its preparation method comprises the following steps:

[0057] (1) take each component by weight: organic intercalation montmorillonite (2.0nm interlayer distance) is 95Kg, acrylonitrile-styrene copolymer resin is 5Kg,

[0058] (2) Place the other components of the prepared material in the mixer, and mix for 20 minutes to obtain the mixed material;

[0059] (3) Put the mixed material in the internal mixer, feed supercritical carbon dioxide, keep the pressure at 10MPa, the temperature is 230°C, and after melting and banburying for 30s, granulate to obtain the noise reduction masterbatch;

[0060] (4) Take each component by the following weight: PC-1100 is 28Kg, PC-2200 is 29Kg, ABS8391 is 33Kg, MBS (methyl methacrylate-butadiene-styrene copolymer): M521 is 4Kg, The compatibilizer is SZ23110 1Kg, the noise reduction masterbatch is 5Kg, the antioxidant 245 is 0.1Kg, the antioxidant...

Embodiment 2

[0064] The present embodiment provides a kind of PC / ABS alloy with noise-reducing performance, and its preparation method comprises the following steps:

[0065] (1) Take each component by weight: organic intercalation montmorillonite (2.3nm interlayer distance) is 95Kg, acrylonitrile-styrene copolymer resin is 3Kg, and coupling agent KH550 is 2Kg;

[0066] (2) Place the other components of the prepared material in the mixer, and mix for 20 minutes to obtain the mixed material;

[0067] (3) Put the mixed material in the internal mixer, feed supercritical carbon dioxide, keep the pressure at 15MPa, and the temperature is 200°C, after melting and banburying for 2 minutes, granulate to obtain the masterbatch;

[0068] (4) Take each component by weight: PC-1100 is 30Kg, PC-2200 is 30Kg, ABS8391 is 29Kg, MBS (methyl methacrylate-butadiene-styrene copolymer): M521 is 3Kg, The compatibilizer is SZ23110 1Kg, the noise reduction masterbatch is 7Kg, the antioxidant 245 is 0.1Kg, the an...

Embodiment 3

[0072] The present embodiment provides a kind of PC / ABS alloy with noise-reducing performance, and its preparation method comprises the following steps:

[0073] (1) each component is taken by weight: organic intercalation montmorillonite (layer spacing 2.8nm) is 90Kg, acrylonitrile-styrene copolymer resin is 7Kg, and coupling agent KH550 is 3Kg;

[0074] (2) Place the other components of the prepared material in the mixer, and mix for 20 minutes to obtain the mixed material;

[0075] (3) Put the mixed material in the internal mixer, feed supercritical carbon dioxide, keep the pressure at 20MPa, and the temperature is 190°C, after melting and banburying for 5 minutes, granulate to obtain the masterbatch;

[0076] (4) Take each component by weight: PC-1100 is 30Kg, PC-2200 is 30Kg, ABS8391 is 29Kg, MBS (methyl methacrylate-butadiene-styrene copolymer): M521 is 5Kg, The compatibilizer is SZ23110 1Kg, the noise reduction masterbatch is 5Kg, the antioxidant 245 is 0.1Kg, the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com