Preparation method of polyvinyl acetate woodworking adhesive with long open time

A polyvinyl acetate and vinyl acetate technology, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, etc., can solve the problems of insufficient bonding strength and insufficient opening time of the glue, and achieve The effect of extending the opening hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

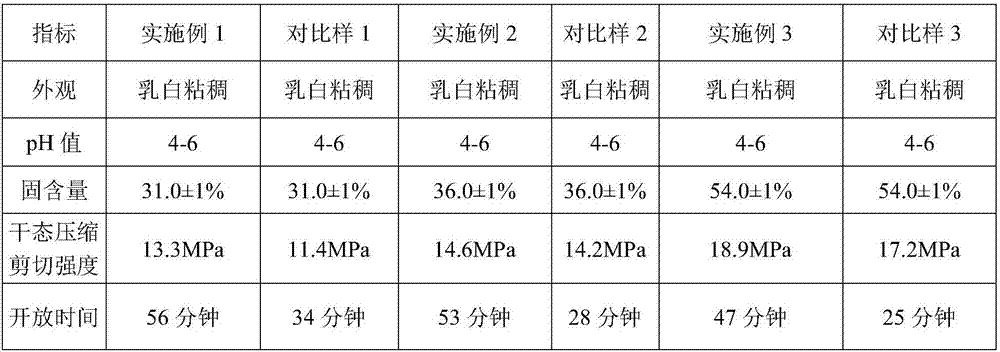

Examples

Embodiment 1

[0014] Embodiment one total amount=1000kg

[0015] (1) 1 kilogram of ammonium persulfate is dissolved in 50 kilograms of water, obtains the ammonium persulfate initiator solution of polymerization;

[0016] (2) 210 kilograms of vinyl acetate, 50 kilograms of hydroxyethyl methacrylate, and 3 kilograms of diacetone acrylamide are mixed and stirred evenly to make 263 kilograms of mixed monomers;

[0017] (3) Add 634 kg of water, 1 kg of defoamer F681, 1 kg of buffer sodium bicarbonate, 3 kg of emulsifier Co436 into the reaction kettle, add 10 kg of PVA2488 and 10 kg of PVA1788 under the condition of dispersing and stirring, stir and disperse for 10 minutes Then heat up to 85°C to dissolve for 50 minutes, then cool down to 50°C, add 20 kg of vinyl acetate and 15 kg of ammonium persulfate solution, stir and disperse for 10 minutes;

[0018] (4) Raise the temperature to 72°C, keep warm for 15 minutes until there is no reflux, and add 263 kg of mixed monomers in step (2) dropwise wi...

Embodiment 2

[0019] Embodiment two total amount=1000kg

[0020] (1) 2 kilograms of ammonium persulfate are dissolved in 50 kilograms of water, obtain the ammonium persulfate initiator solution of polymerization;

[0021] (2) 240 kilograms of vinyl acetate, 100 kilograms of hydroxyethyl methacrylate, and 5 kilograms of diacetone acrylamide are mixed and stirred evenly to make 345 kilograms of mixed monomers;

[0022] (3) Add 548 kg of water, 1 kg of defoamer F681, 2 kg of buffer sodium bicarbonate, 4 kg of emulsifier Co436 into the reaction kettle, add 10 kg of PVA2488 and 30 kg of PVA1792 under the condition of dispersing and stirring, stir and disperse for 10 minutes Then heat up to 85°C to dissolve for 50 minutes, then cool down to 50°C, add 20 kg of vinyl acetate and 15 kg of ammonium persulfate solution, stir and disperse for 10 minutes;

[0023] (4) Raise the temperature to 72°C, keep warm for 15 minutes until there is no reflux, and add 345 kg of mixed monomers in step (2) with a co...

Embodiment 3

[0024] Embodiment three total amount=1000kg

[0025] (1) 2 kilograms of ammonium persulfate are dissolved in 50 kilograms of water, obtain the ammonium persulfate initiator solution of polymerization;

[0026] (2) 29 kilograms of vinyl acetate, 150 kilograms of hydroxyethyl methacrylate, and 8 kilograms of diacetone acrylamide are mixed and stirred evenly to make 448 kilograms of mixed monomers;

[0027] (3) Add 400 kg of water, 2 kg of defoamer F681, 2 kg of buffer sodium bicarbonate, and 5 kg of emulsifier Co436 into the reaction kettle, add 60 kg of polyvinyl alcohol PVA1792 under the condition of dispersing and stirring, and stir and disperse for 10 minutes Heat up to 90°C to dissolve for 60 minutes, then cool down to 60°C, add 30 kg of vinyl acetate and 15 kg of ammonium persulfate solution, stir and disperse for 15 minutes;

[0028] (4) Raise the temperature to 78°C, keep it warm for 15 minutes until there is no reflux, and add 448 kg of mixed monomers in step (2) dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com