Heat insulation board with improved structure

A technology of thermal insulation board and thermal insulation layer, which is applied in the field of thermal insulation of board materials, can solve problems such as waste of resources, potential safety hazards, and difficulty in meeting requirements, and achieve the effects of increasing service life, promoting physical health, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

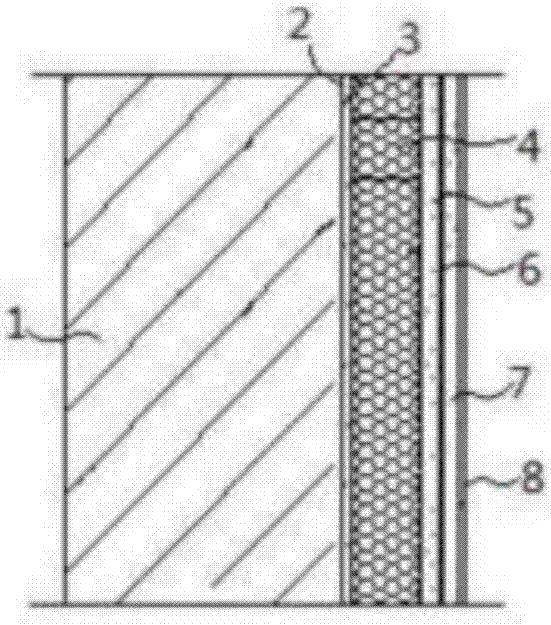

[0018] Such as figure 1 As shown, a structure-improved insulation board of this embodiment includes a base layer 1, a first adhesive 2, an interface layer 3, an insulation layer 4, a protective layer 5, a reinforcement layer 6, a flexible putty 7, a finishing layer 8 and a second Two adhesives; one side of the insulation board is provided with a base layer 1, and the other side of the insulation board is provided with a facing layer 8; the base layer 1 is poured into concrete by the concrete cast-in-place method, and one side of the base layer 1 is provided with an insulation layer 4 for heat preservation The two sides of the layer 4 are supplemented with cement polymer sheets as the surface layer, and an interface layer 3 is arranged between the insulation layer 4 and the base layer 1, and the interface layer 3 is bonded to the base layer 1 and the insulation layer 4 respectively through the first adhesive 2; A reinforced layer 6 is provided on the side of the layer 4 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com