High-emission-rate and high-collection-efficiency single photon source device

A single-photon source, emission rate technology, applied in the field of quantum information and ion-polar photonics, to achieve the effect of improving emission rate and huge application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

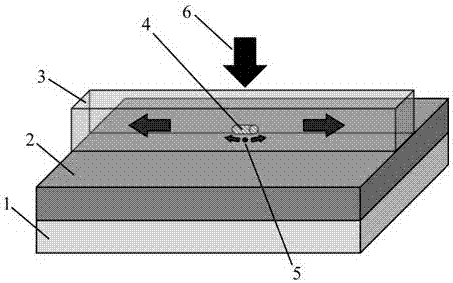

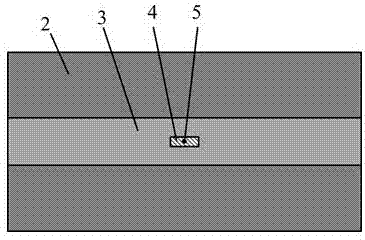

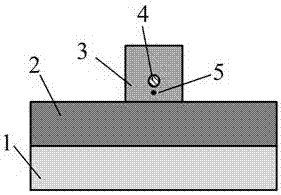

[0029] as attached figure 1 , 2 , 3, the present invention provides a single-photon source device with high emission rate and high collection efficiency based on gap plasmons and dielectric-carried surface plasmon waveguides, the single-photon source device includes SiO 2 A substrate 1 , a medium-carrying surface plasmon waveguide, a gap plasmon microcavity, and a quantum dot 5 .

[0030] The gap plasmon microcavity is composed of a metal thin film 2 and a metal nanorod 4 for forming a gap plasmon; wherein: the metal thin film 2 is a gold thin film, and the metal nanorod 4 is a gold nanorod.

[0031] The quantum dot 5 is located in the gap plasmon microcavity composed of the gold film 2 and the gold nanorod 4; the medium-loaded surface plasmon waveguide includes the gold film 2 and SiO 2 The dielectric strip 3 is used to collect photons emitted by the quantum dots 5 . The distance between the gold nanorod 4 and the gold film 2 is 10nm, the quantum dot 5 is located in the mi...

Embodiment 2

[0044] A high emission rate, high collection efficiency single-photon source device based on gap plasmons and dielectric-supported surface plasmon waveguides, such as figure 1 , 2 , 3, the single photon source device includes Si substrate 1, silver film 2, Si 3 N 4 Dielectric strip 3, gold nanorod 4 and fluorescent molecule 5.

[0045] The silver thin film 2 and the gold nanorod 4 constitute a gap plasmon microcavity, which is used to form a gap plasmon; the fluorescent molecule 5 is located in the gap plasmon microcavity composed of the silver thin film 2 and the gold nanorod 4; the silver Film 2 and Si 3 N 4 The dielectric strip 3 forms a dielectric-carried surface plasmon waveguide for collecting photons emitted by the fluorescent molecules 5 .

[0046]The distance between the gold nanorod 4 and the silver film 2 is 10nm, the fluorescent molecule 5 is located in the middle of the interstitial plasmon microcavity, and the distance from the upper surface of the silver fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com