Automobile electrical machine heat dissipation fan noise-reduction and anti-vibration system

A motor cooling and fan technology, applied in the field of auto parts, can solve problems such as the deterioration of the working condition of the cooling fan, the increase of the working noise of the cooling fan, and the aggravation of the rotational vibration of the fan blades, so as to improve the NVH performance, avoid the vibration noise, and improve the work. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

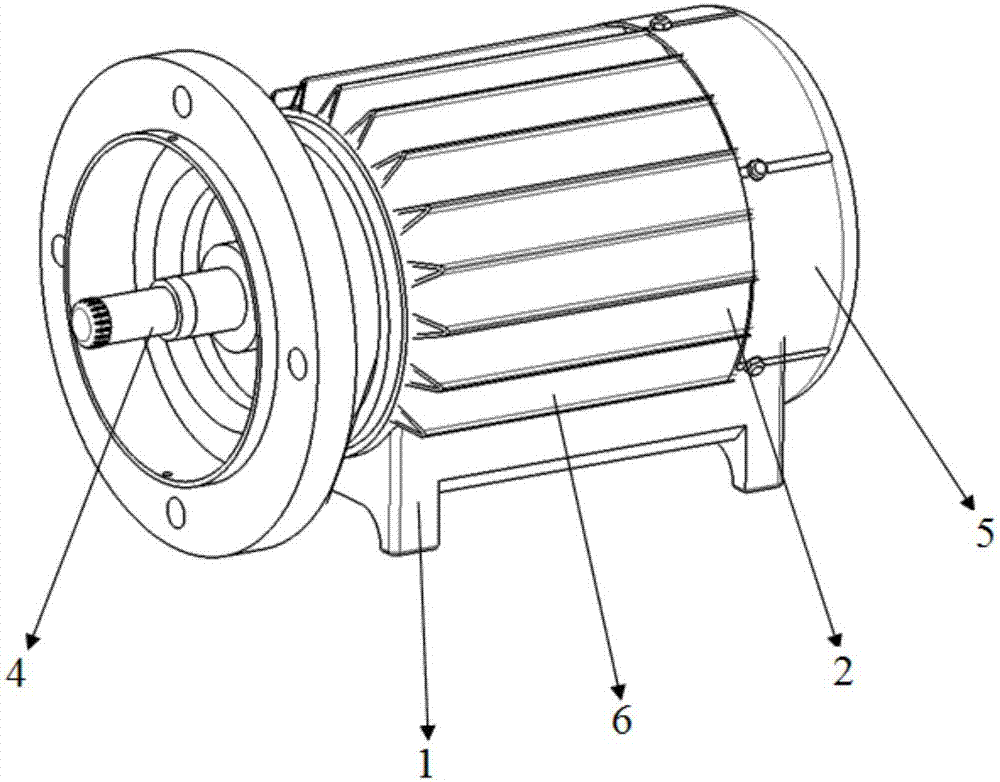

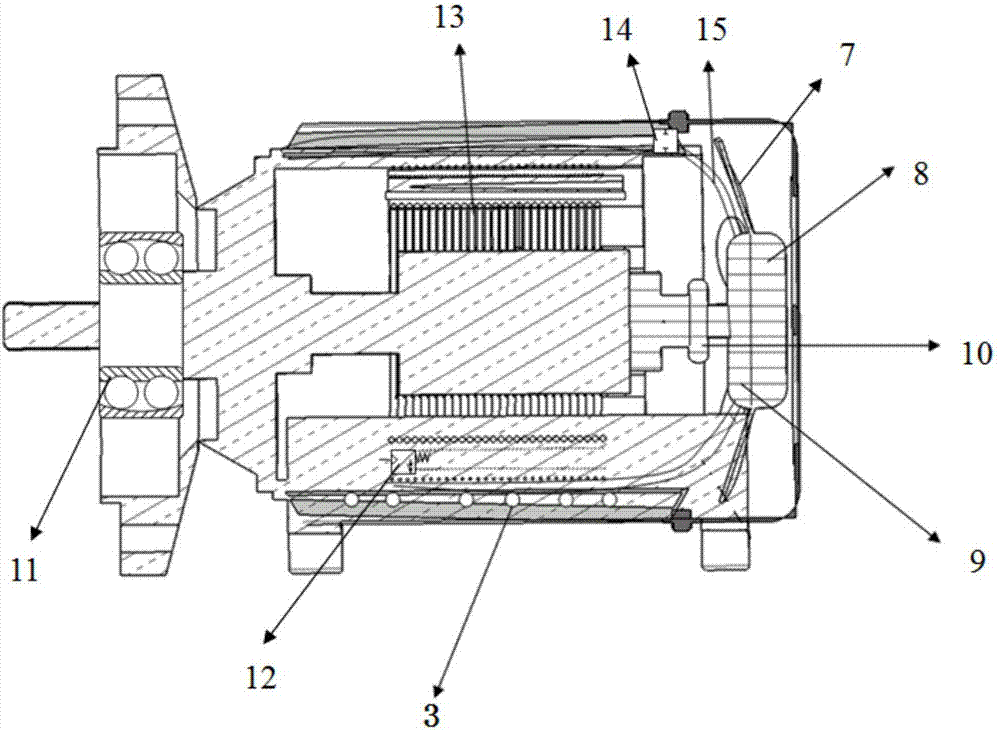

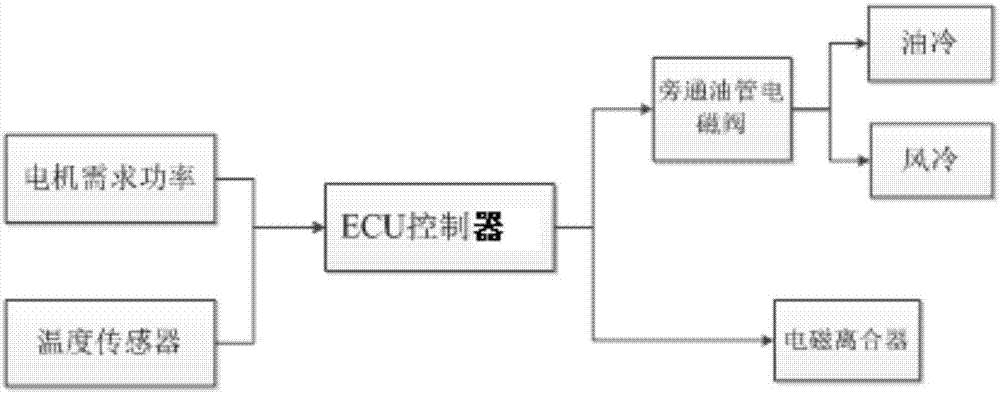

[0030] Such as Figure 1-2 As shown, an automotive motor cooling fan noise reduction and anti-vibration system, the motor includes a base 1, a motor housing 2 arranged on the base 2, a rear cover 5 fixedly connected to the motor housing 2, and evenly arranged on The radiating fins 6 on the motor housing 2, the drive shaft 4 and the electromagnetic coil 13 arranged in the motor housing 2. The device includes a fluid coupling that is connected to the drive shaft 4 in transmission, and is evenly arranged on the fluid coupling The radiating fan 7 around the turbine 8 of the turbocharger, the electromagnetic clutch 10 that connects the pump wheel 9 of the hydraulic coupling with the drive shaft 4, the bypass cooling oil pipe 15 arranged between the electromagnetic coils 13, and the bypass cooling oil pipe The solenoid valve 14 on 15 and the ECU controller electrically connected with the fluid coupling, the electromagnetic clutch 10 and the solenoid valve 14 respectively.

[0031] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com